On-site calibration test line self-priming cable management clip

An on-site calibration and test line technology, applied in the direction of measuring devices, measuring electrical variables, and parts of electrical measuring instruments, can solve the problems of falling off, complex structure, inconvenience, etc., and achieve reliable finishing and fixing, and realize fixed limit , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

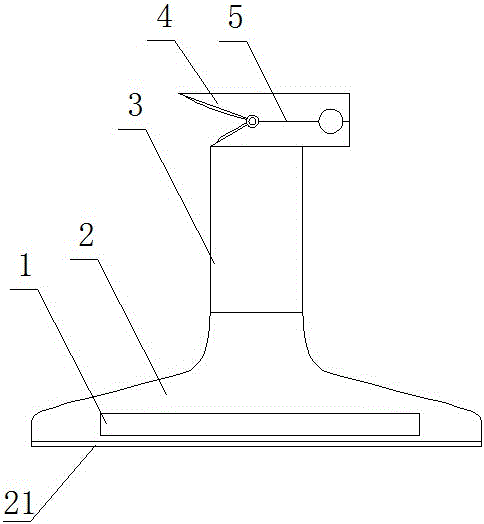

[0032] Such as figure 1 Shown: a field verification test line self-priming type cable management clip, including a base 2 with a strong magnet 1, a test line fixed support 3 that is threaded and movably connected to the base 2, and the test line fixed support 3 There is a push-type test line fixing mechanism 5 on the top, and the push-type test line fixing mechanism 5 is a spring clip. The upper and lower clips of the spring clip are provided with opposite arc-shaped grooves for holding the test line to avoid loss. At the same time, the tail of the upper clip body of the spring clip is longer than the lower clip body, which is convenient for labor-saving and more convenient when pressing. The bottom of the base 1 is provided with a buffer pad 21, and the buffer pad 21 is a rubber pad. Both the base 1 and the test line fixing support 3 are made of hard plastic.

Embodiment 2

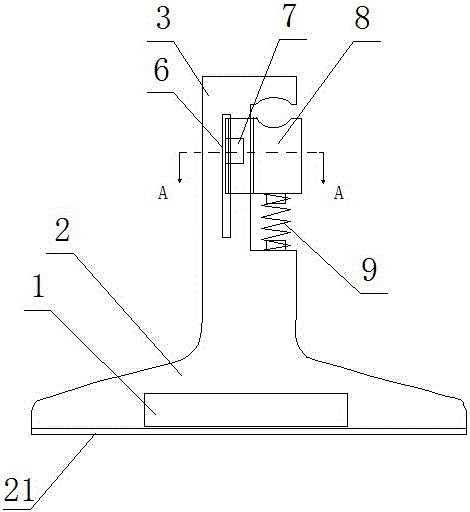

[0034] Such as Figure 2-4 Shown: a self-suction cable management clip for on-site verification test lines, including a base 2 with a strong magnet 1 and a test line fixing support 3 integrated with the base 2, and the test line fixing support 3 is set There is a sliding sleeve 8, the side of the test line fixing support 3 is provided with an open slot 10, the top of the open slot 10 is provided with an upper arc groove, and the top of the sliding sleeve 8 is provided with a The lower arc-shaped groove corresponding to the shaped groove, the opening groove 10 of the test line fixing support 3 has a strip-shaped hole 6 parallel to the opening groove 10, and one side of the sliding sleeve 8 has a Shaped hole 6 fits and 11 of the sliding surface that slides in described bar-shaped hole 6, and described sliding sleeve 8 is also provided with pressing member 7, and described pressing member 7 is pressing block or pressing plate, and described sliding sleeve 8 The bottom of the ope...

Embodiment 3

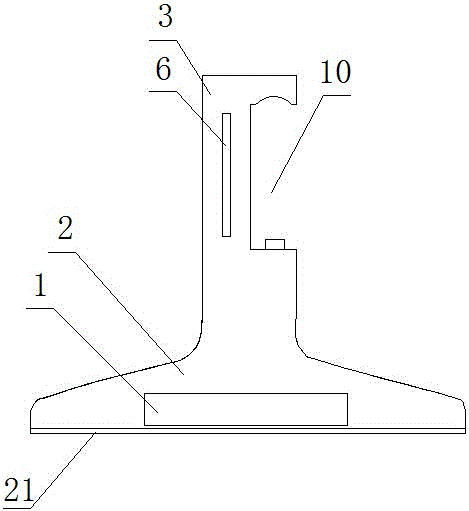

[0036] Such as Figure 3-10 Shown: a self-priming cable management clip for on-site verification test line, including a base 2 with a strong magnet 1 and a test line fixing support 3 arranged on the base 2, and a rubber buffer is provided at the bottom of the base 2 Pad 21. The test line fixing support 3 is provided outside the test line fixing support 3, which includes a support body arranged on the base 2 and having an open groove 10 on the side, and a support body that is sleeved outside the support body and is connected with the support body. The sliding sleeve 16 that is slidably connected to the support body, the pressing sleeve 12 is arranged outside the sliding sleeve 16, the sliding sleeve is movably connected with the support body through a locking mechanism, and the locking mechanism includes setting The slider 13 and the elastic mechanism in the open groove 10, the top of the open groove 10 and the top of the slider 13 are provided with a symmetrical arc wire slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com