Annular magnetic ultrasonic transducer applicable to pipeline installation

A pipeline installation and ultrasonic technology, applied in the direction of fluid using vibration, cleaning method using liquid, chemical instrument and method, etc., can solve the problems of reducing equipment performance, reducing flow area, reducing heat transfer coefficient, etc. Conduction distance, uniform distribution in all directions, favorable for aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

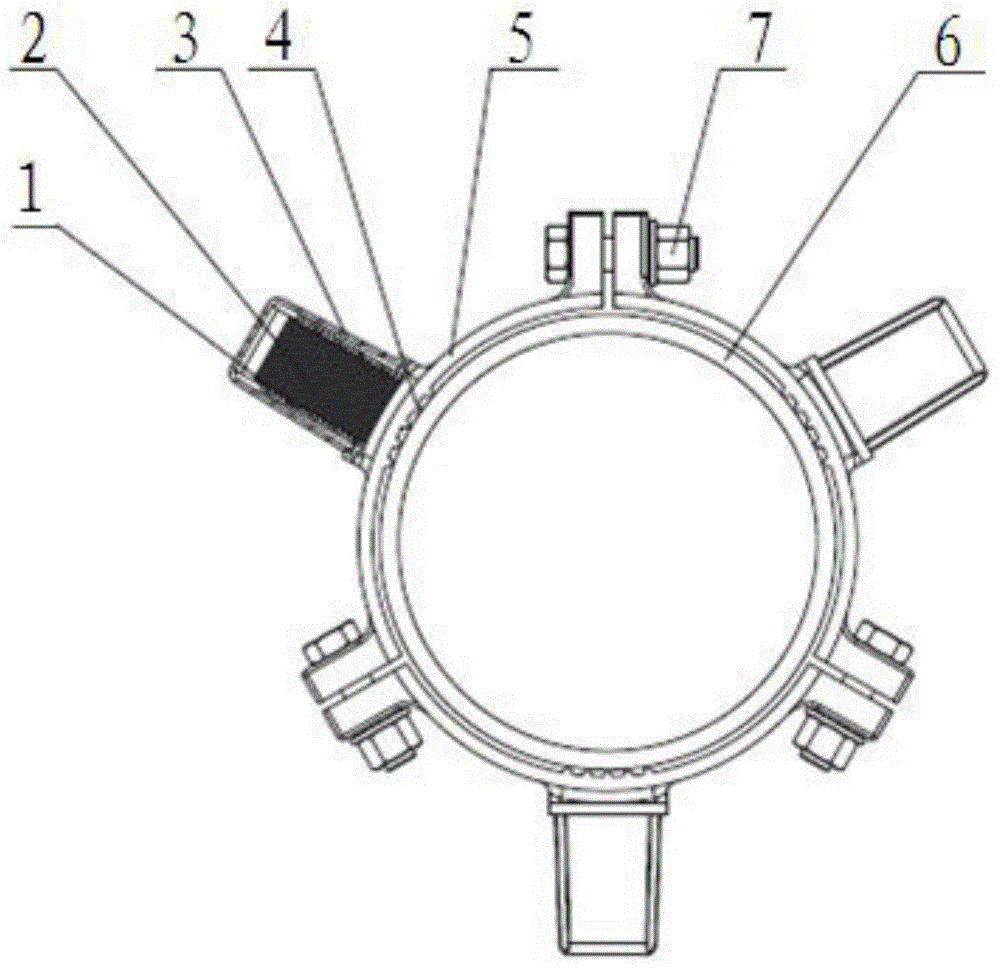

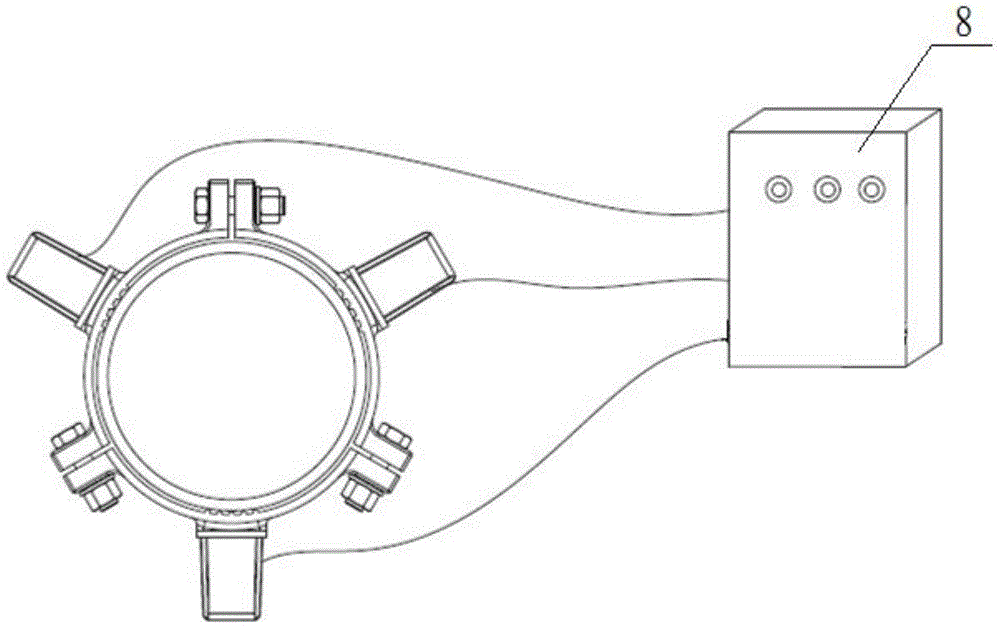

[0022] Such as figure 1 , figure 2 As shown, the technical solution of the present invention is: a ring-shaped magneto-ultrasonic transducer suitable for pipeline installation, including an excitation coil 1, a magnetostrictive body 2, an electrical protection shell 3, an energy conducting ring 5, a connecting Part 7 and ultrasonic controller 8;

[0023] Wherein, the excitation coil 1 is three groups; the magnetostrictive body 2 is three;

[0024] The energy conducting ring piece 5 is three pieces, the energy conducting ring piece 5 is an arc plate structure, and the two ends of the energy conducting ring piece 5 extend outward to form a convex edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com