Device for unidirectional straight drawing forming of high-strength metal wire

A metal wire, straight-forward technology, applied in the direction of wire drawing dies, etc., can solve the problems of performance impact, poor dimensional stability of finished products, etc., and achieve stable quality, reduced bending and twisting, and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below with reference to the drawings and specific embodiments:

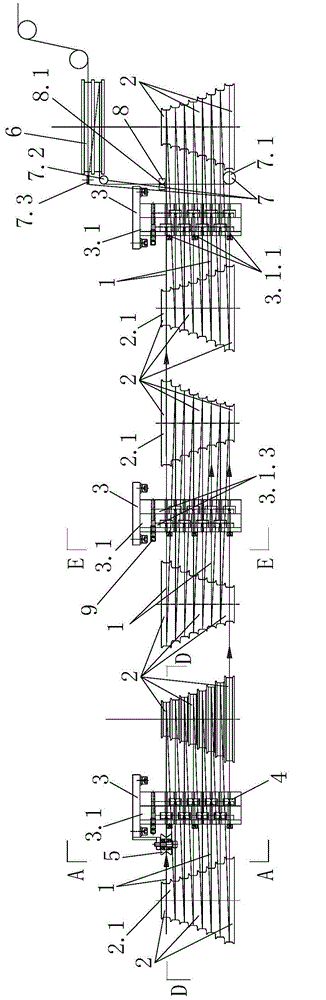

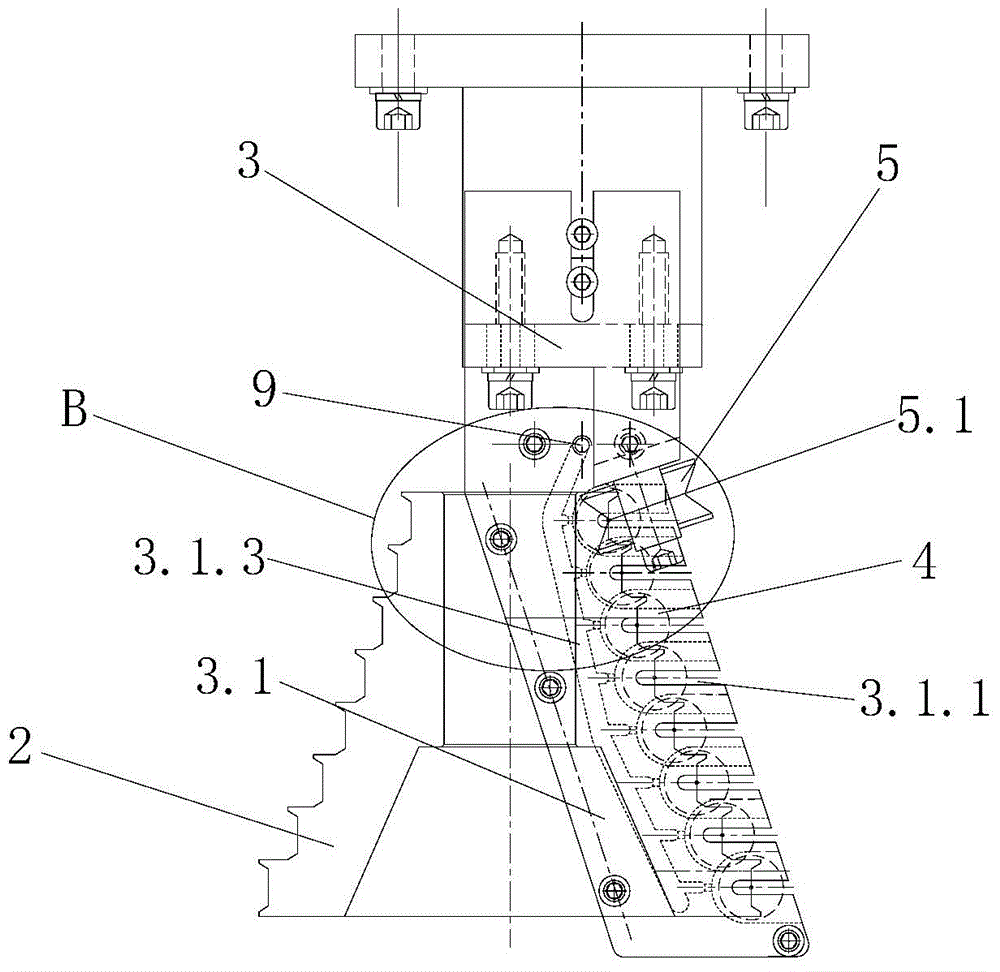

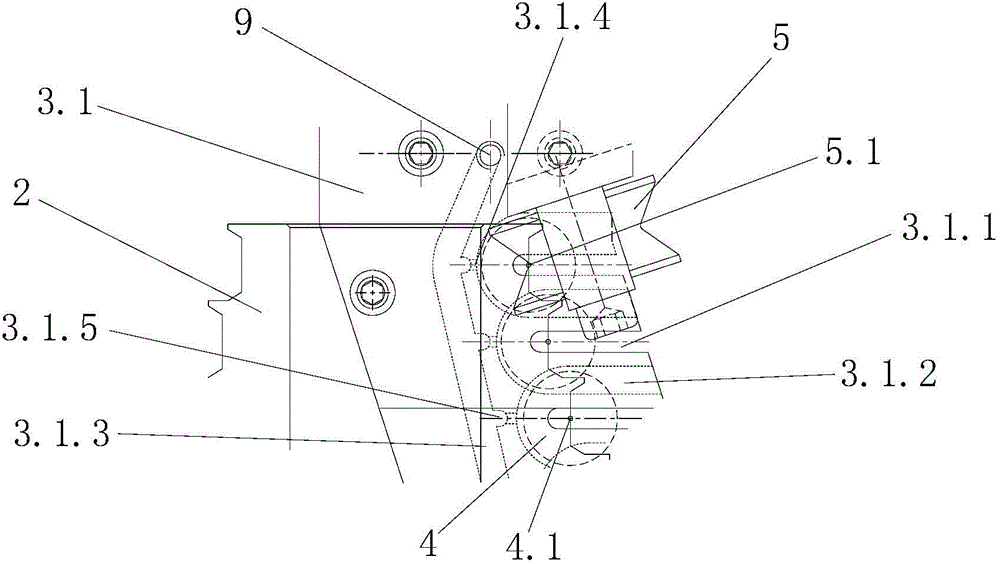

[0048] See Figure 1 to Figure 7 , The one-way straight wire drawing device for high-strength metal wire of the present invention includes a tower wheel set 2, a die box 3, an embedded wire drawing die 4, a wire crimping wheel 5, a traction wheel 6, and a reversing wire wheel 7. Longitudinal drawing die 8 and nozzle 9.

[0049] See Figure 2 to Figure 7 , All tower wheel groups 2 are arranged in a straight line, every two tower wheel groups 2 are arranged in the same direction, and the two adjacent pairs of tower wheel groups 2 are arranged in opposite directions, the first pair of tower wheel groups 2 and the third pair of tower wheels Group 2 is arranged in a regular trapezoid with a small head and a big bottom, and the second pair of tower wheels 2 is arranged in an inverted trapezoid with a small head and big bottom. There are three pairs of tower w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com