Method for producing inspection well cover and evanescent mold for casting inspection well cover

A production method and manhole cover technology, which are applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of serious environmental pollution, complex production process, and many production process points, and achieve serious environmental pollution and process yield. Low, labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

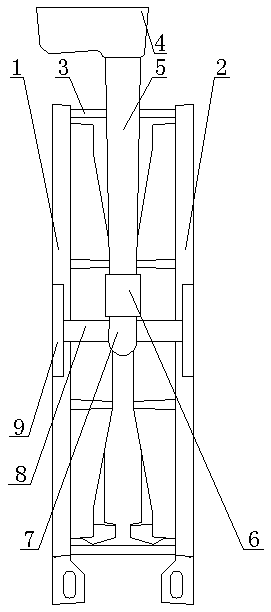

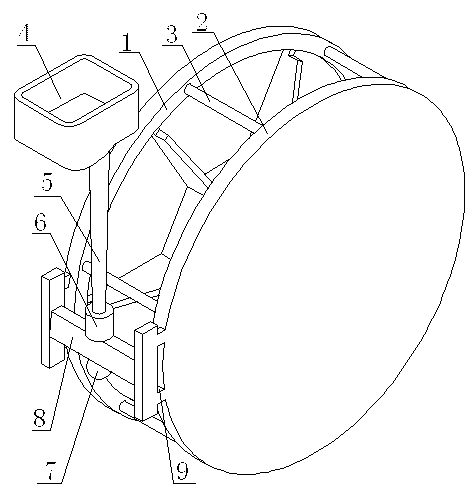

[0021] Embodiment 1: see figure 1 and figure 2 , the lost pattern of casting manhole cover has the first lost pattern 1; the second lost pattern 2; the lost pattern of the sprue buffer chamber 7; the lost pattern of the runner 8; the lost pattern of the sprue 5; ; ceramic connecting sleeve 6; a plurality of coated sand supports 3, the first disappearing pattern 1 and the second disappearing pattern 2 are connected symmetrically with six coated sand supports 3; the sprue buffer chamber disappearing pattern 7 is located in the The bottom of the runner disappearing pattern 8 is integrated with it; the two ends of the runner disappearing pattern 8 are respectively connected with the inner runner disappearing pattern 9 of the first disappearing pattern 1 and the second disappearing pattern 2; the sprue The disappearing pattern 5 and its integrated sprue cup disappearing pattern 4 are connected to the runner disappearing pattern 8 through a ceramic connecting sleeve 6 .

[0022] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap