Hydraulic starting system, method and crane

A hydraulic start and cold start technology, applied in the hydraulic field, can solve the problems of hydraulic system resistance torque increase, system compound action limitation, poor engine adaptability, etc., to achieve the effect of avoiding resistance torque and smooth start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

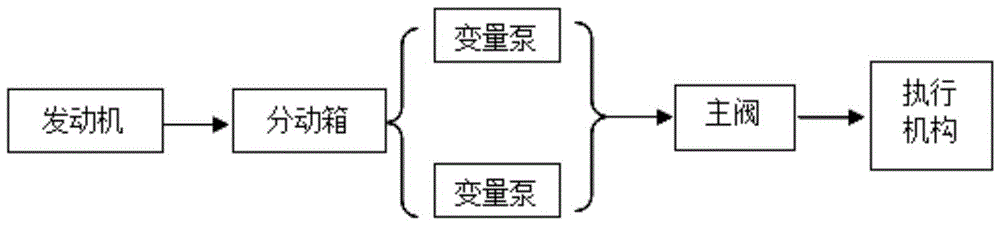

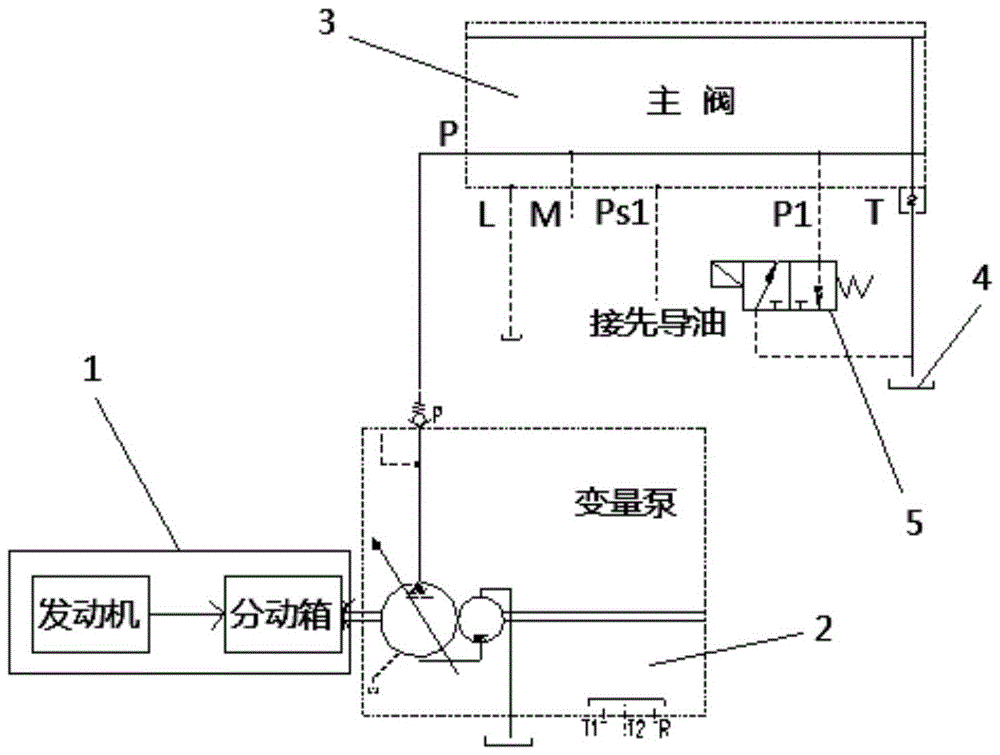

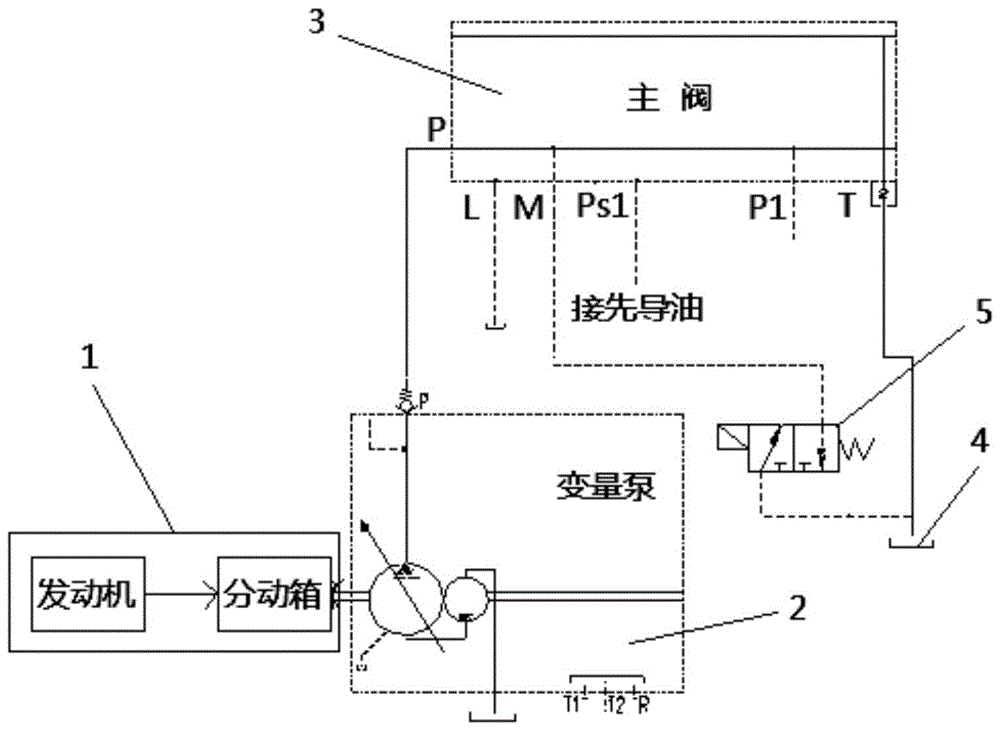

[0029] like figure 2 Shown is a schematic structural view of an embodiment of the hydraulic starting system of the present invention. In this embodiment, the hydraulic starting system includes: a power mechanism 1, a variable pump 2, a main valve 3 and a hydraulic oil tank 4. The power mechanism 1 provides driving power to the variable pump 2. connected through the oil circuit.

[0030] The main valve 3 is provided with a plurality of oil ports, among which the oil inlet P is connected with the oil supply circuit of the variable pump 2, and the main valve 3 also has a cold start oil drain port, between the cold start oil drain port and the hydraulic oil tank 4 There is a solenoid valve 5 that controls the discharge of the variable displacement pump 2 during cold start. During cold start, the system can use the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com