A kind of preparation method of titanium-based amorphous coating on the surface of titanium alloy

A technology of amorphous coating and titanium alloy, which is applied in the field of preparation of titanium-based amorphous coating on the surface of titanium alloy, can solve the problems of low work hardening ability, adhesive wear, poor friction performance of titanium alloy, etc. The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

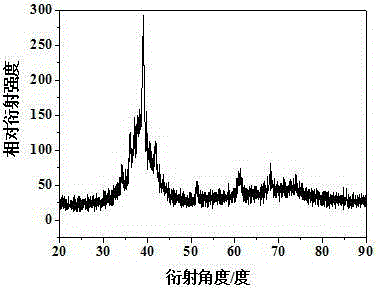

[0025] Now take the titanium alloy Ti6Al4V as an example, and the titanium-based amorphous composite material is Ti46Zr20V12Cu5Be17.

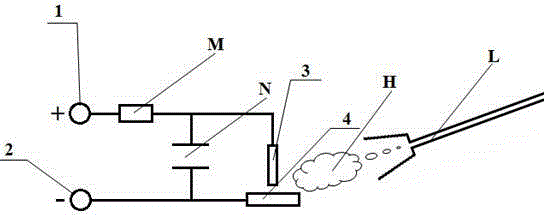

[0026] Implement the present invention, such as figure 1 Shown:

[0027] (1) Pretreatment of the titanium alloy workpiece: after degreasing the surface of the titanium alloy workpiece 4, use SiC water sandpaper to grind, clean and dry the titanium alloy workpiece step by step;

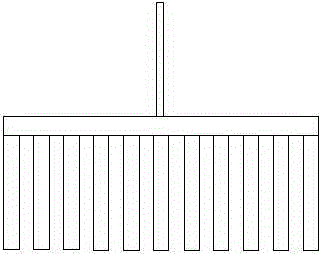

[0028] (2) Connect the pretreated titanium alloy workpiece 4 to the cathode 2 of the power supply of the surface strengthening processor to become a workpiece pole, and then connect the comb-shaped titanium-based amorphous composite material 3 to the anode 1 of the power supply of the surface strengthening processor through a clamp , become the processing electrode;

[0029] (3) Turn on the power of the surface strengthening processor, apply a DC voltage of 15-70V between the workpiece pole and the processing electrode, when the distance between the workpiece pole an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com