Flexible dye-sensitized solar cell and preparation method thereof

A dye-sensitized, solar cell technology, applied in the field of flexible dye-sensitized solar cells and their preparation, can solve problems such as adverse effects on device efficiency and lifespan, high requirements for preparation instruments, complicated processes, etc., and achieves improved photoelectric conversion efficiency, The effect of low resistivity and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a flexible dye-sensitized solar cell, comprising the steps of:

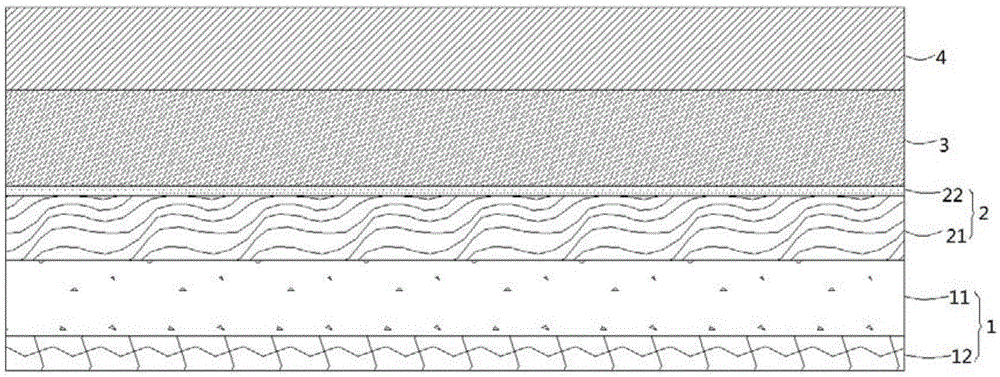

[0031] S1. Select a rigid substrate, and prepare a flexible silver nanowire polymer composite conductive substrate layer 1 on the rigid substrate;

[0032] S2. Prepare the oxide porous film layer 21 on the flexible silver nanowire polymer composite conductive substrate layer 1 prepared in step S1, then soak the oxide porous film layer 21 in the dye solution, after cleaning Dry to obtain photoanode layer 2;

[0033] S3, making a counter electrode layer 4 on the surface of the flexible silver nanowire polymer composite conductive substrate layer 1;

[0034] S4. Pouring electrolyte dye between the photoanode layer 2 and the counter electrode layer 4 to form the electrolyte layer 3 .

[0035] In the step S1, the preparation process of the flexible silver nanowire polymer composite conductive substrate layer 1 includes: ①. Prepare the configured silver nanowire dispersion solution on th...

Embodiment 1

[0040] S1. Preparation of the flexible silver nanowire polymer composite conductive substrate layer 1: select the glass substrate and clean it, and configure the isopropanol dispersion solution of the silver nanowire at room temperature, wherein the mass concentration of isopropanol is 0.1%-1%. , coated on the cleaned glass substrate surface with a squeegee bar to make a silver nanowire thin film layer 11 with a thickness of 0.7 μm, the transmittance of the silver nanowire thin film layer 11 is as high as 83%; The acrylate monomer with a concentration of 1-5% photoinitiator is spin-coated on the surface of the silver nanowire film layer 11, and then the silver nanowire film layer 11 coated with the acrylate monomer is placed under an ultraviolet lamp to initiate Acrylate monomers are polymerized to obtain a polymer layer 12 with a thickness of 300 μm, and the glass substrate is removed after cooling to obtain a flexible silver nanowire polymer composite conductive substrate lay...

Embodiment 2

[0046] S1. Preparation of the flexible silver nanowire polymer composite conductive substrate layer 1: select the glass substrate and clean it, and configure the isopropanol dispersion solution of the silver nanowire at room temperature, wherein the mass concentration of isopropanol is 0.1%-1%. , using the screen printing method to prepare the configured dispersion solution on the surface of the cleaned glass substrate to prepare a silver nanowire film layer 11 with a thickness of 0.5 μm, and the transmittance of the silver nanowire film layer 11 is as high as 90%. Then the acrylate monomer of the photoinitiator added with the mass concentration of 1 to 5% is drop-coated on the surface of the silver nanowire film layer 11, and then the silver nanowire film layer 11 coated with the acrylate monomer is placed on the Initiate the polymerization of acrylate monomers under an ultraviolet lamp to obtain a polymer layer 12 with a thickness of 500 μm, and remove the glass substrate aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com