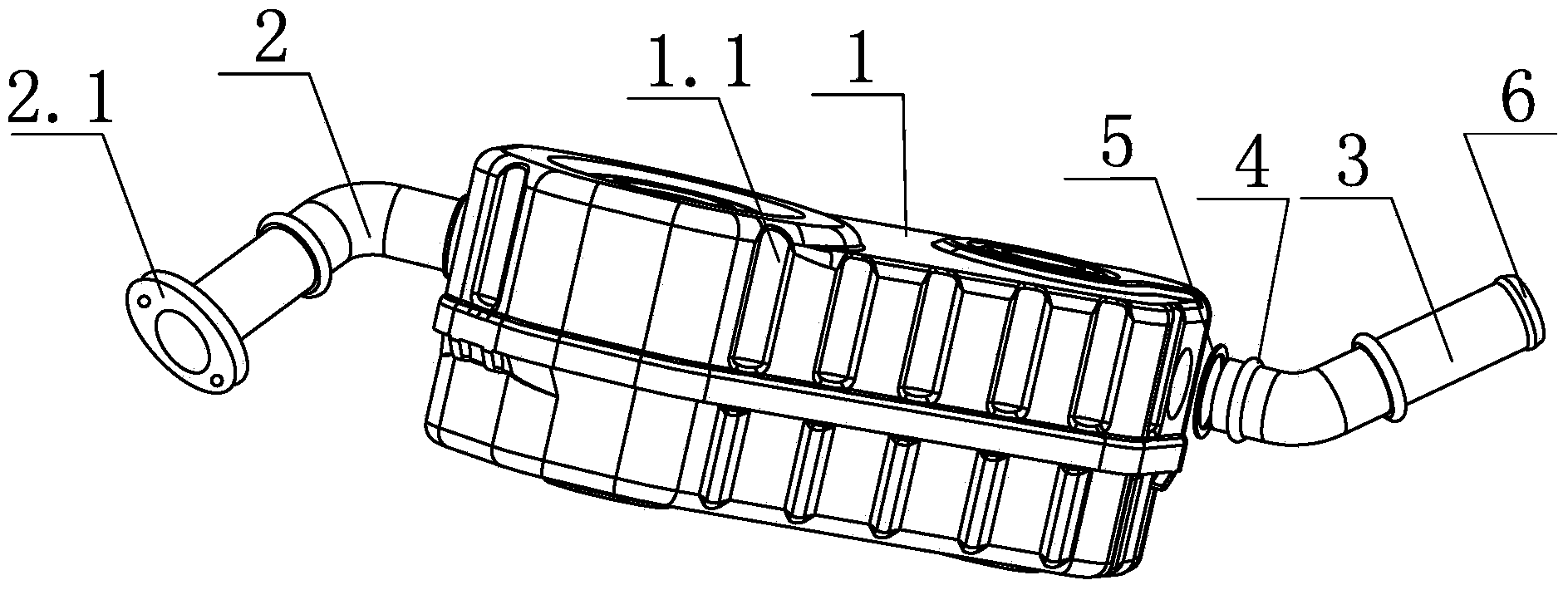

Aluminum oil cooler

An oil cooler, aluminum base material technology, applied in machine/engine, engine cooling, engine components, etc., can solve the problems of affecting product reliability, small welding area, poor welding seam quality, etc., to increase flow spreadability , The effect of increasing the welding area and saving flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

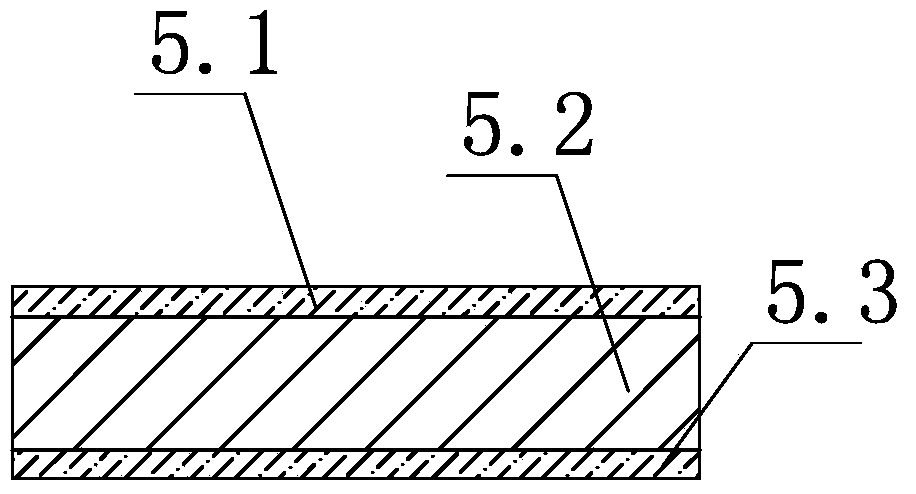

[0019] Embodiment 1: The components and weight percentages of the upper solder layer 5.1 and the lower solder layer 5.3 are:

[0020] Si5%; Fe0.1%; Mn0.005%; Mg1%; Bi0.1%; Sr0.05%; P0.001%, Ge0.002%, and the rest is Al.

Embodiment 2

[0021] Embodiment 2: The components and weight percentages of the upper solder layer 5.1 and the lower solder layer 5.3 are:

[0022] Si12%; Fe1.0%; Mn0.025%; Mg2.5%; Bi0.3%; Sr0.25%; P0.01%, Ge0.03%, and the rest is Al.

Embodiment 3

[0023] Embodiment 3: The components and weight percentages of the upper solder layer 5.1 and the lower solder layer 5.3 are:

[0024] Si10%; Fe0.8%; Mn0.02%; Mg2%; Bi0.15%; Sr0.18%; P0.007%, Ge0.01%, the rest is Al.

[0025] The preparation method of specific embodiment solder involved in the present invention comprises the steps:

[0026] 1. Put all the above-mentioned material components in a furnace in proportion to process them into alloys.

[0027] 2. The alloy processed in the above steps is crystallized in proportion to obtain the solder of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com