Ceramic plug valve

A plug valve and ceramic technology, which is applied in the field of ceramic plug valves, can solve the problems that the channel is not provided with a ceramic lining, and the advantages of the ceramic material cannot be fully reflected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

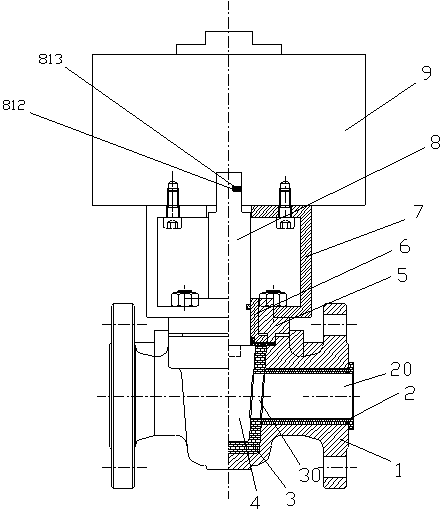

[0036] like figure 1 As shown, the embodiment of the present invention includes a valve body 1, a channel lining 2, a cavity lining 3, a cock 4, a valve cover 5, a stuffing box 6, a bracket 7, a cock rod 8, an actuator 9, an anti-static spring 812, Steel ball 813.

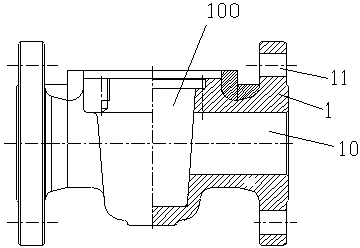

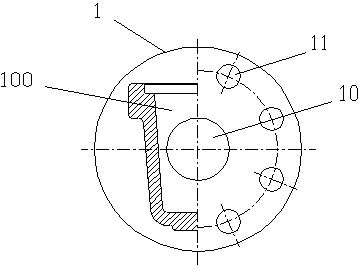

[0037] Specifically, as figure 1 , figure 2 , image 3 As shown, the valve body 1 includes a cavity 100 in the center and passages 10 on both sides. The passage 10 and the cavity 100 pass through. The outer edge of the passage 10 is provided with a through hole 11 to facilitate connection with the pipe flange.

[0038] like figure 1 , Figure 5 , Image 6 As shown, the cavity lining 3 is made of ceramic material, in the shape of a barrel, thick at the top and thin at the bottom. The interior of the cavity lining 3 is a cavity 300 conforming to the contour of the coc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com