A kind of macro-preparation device and method of carboxyl functionalized graphene

A technology for preparing devices and fossils, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of complex preparation process, inability to disperse well, and low reactivity, and achieve good dispersion effect and improved mechanical properties. The effect of good sexual effect and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

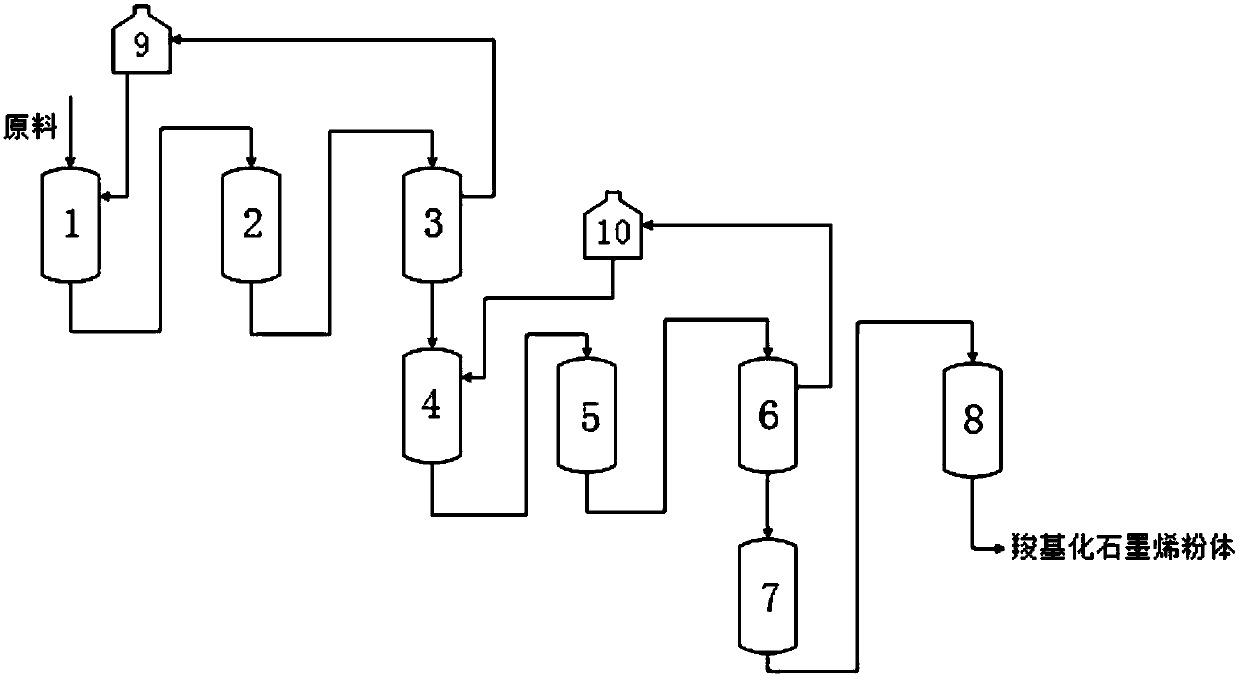

[0038] A kind of macro-preparation device of carboxyl functionalized graphene of the present embodiment, such as figure 1 As shown, it includes the first dispersion tank 1, activation reactor 2, first filter washing tower 3, second dispersion tank 4, reaction kettle 5, second filter washing tower 6, third dispersion tank 7, drying tower 8, the first A storage tank 9 and a second storage tank 10, the first dispersion tank 1, the activation reactor 2, the first filter washing tower 3, the second dispersion tank 4, the reaction tank 5, the second filtration washing tower 6, and the third dispersion tank 7 and the drying tower 8 are connected in sequence, the first filter washing tower 3, the first storage tank 9 and the first dispersion tank 1 are connected in sequence, and the second filter washing tower 6, the second storage tank 10 and the second dispersion tank 4 are connected in sequence.

[0039] Among them: the first dispersing kettle 1 is the place where the raw material ...

Embodiment 2

[0050] This embodiment also adopts the device described in Example 1 to carry out the macro-preparation of carboxyl-functionalized graphene, including the following steps:

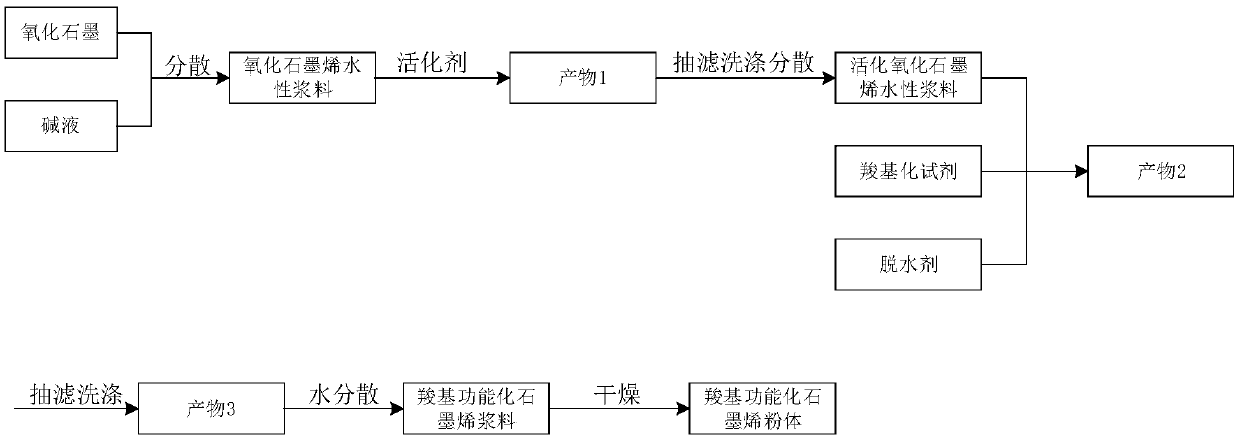

[0051] Step 1, put graphite oxide and sodium hydroxide solution into the first dispersing kettle 1, disperse and strip through the simultaneous operation of high-shear emulsifier and ultrasonic dispersing device, and adjust the amount and concentration of sodium hydroxide solution to make the pH of the system To 8.5, through the cooling coil installed in the kettle, the dispersion temperature is controlled below 40°C, the speed of the high-shear emulsifier is 600r / min, the ultrasonic power is 10kW, and the ultrasonic time is 60min to obtain graphene oxide water-based slurry.

[0052] Step 2: Pass the slurry obtained in Step 1 into the activation reactor 2 through pipeline transportation, and add sodium chloroacetate, after fully stirring, control the reaction temperature at 75°C, and carry out the carboxyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com