Steel-sleeve-steel steam thermal insulation pipe

A technology of steam insulation pipe and steel jacket steel, which is applied in the direction of heat preservation, pipe support through heat insulation, etc. It can solve the problems of steel pipe space reduction, steel pipe can not run smoothly, and become larger, so as to achieve the effect of ensuring thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

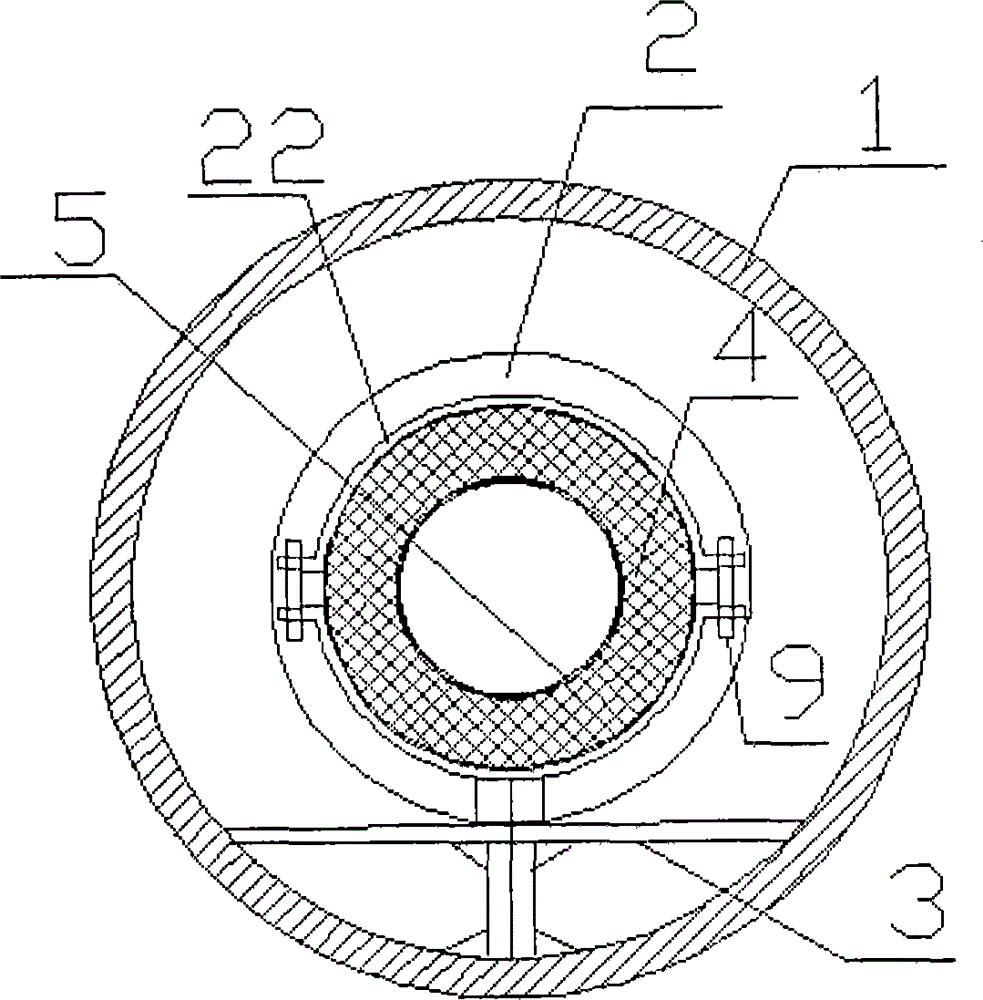

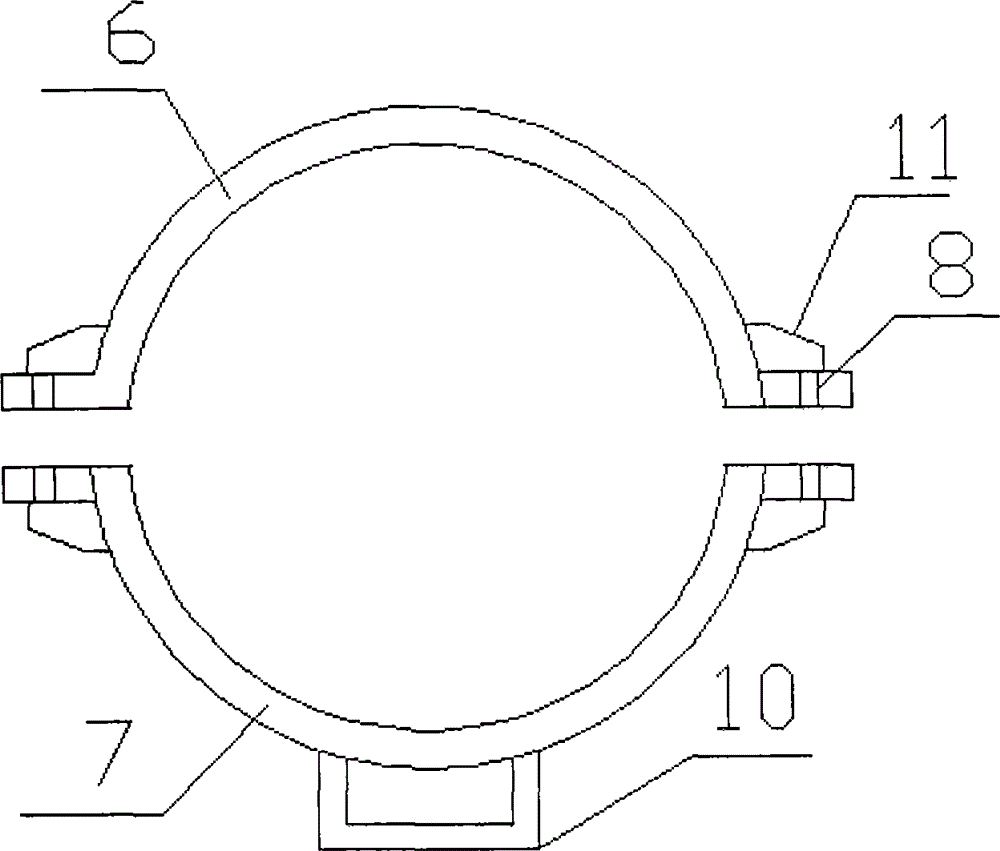

[0014] refer to figure 1 with figure 2 A steel-sheathed steel steam heat insulation pipe shown includes an outdoor steel pipe 1, an insulation layer 2, a bottom support 3, a hard asbestos heat insulation pad 4 and a working steel pipe 5, and the heat preservation layer 2 is installed on the bottom support 3, Between the thermal insulation layer 2 and the hard asbestos heat insulation pad 4, a sliding support 22 that can move longitudinally or laterally is provided. The sliding support 22 is composed of an upper support 6 and a lower support 7. The upper support Both ends of the seat 6 and the lower support 7 are provided with bolt holes 8 and ribs 11, the upper support 6 and the lower support 7 are connected with bolts 9 through the bolt holes 8, and the lower support 7 is also fixedly installed There are bases 10 .

[0015] Wherein, more than four bolt holes 8 are provided.

[0016] More than four ribs 11 are provided.

[0017] The beneficial effects of the automatic sta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap