Air flue applied to ring-pull can aluminum scrap packing machine

A technology of cans and air ducts, applied in transportation and packaging, cleaning methods and utensils, and dust removal, etc., can solve problems such as easy blockage and easy pollution of the environment, and achieve the effect of easy maintenance and replacement, and increase the ventilation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

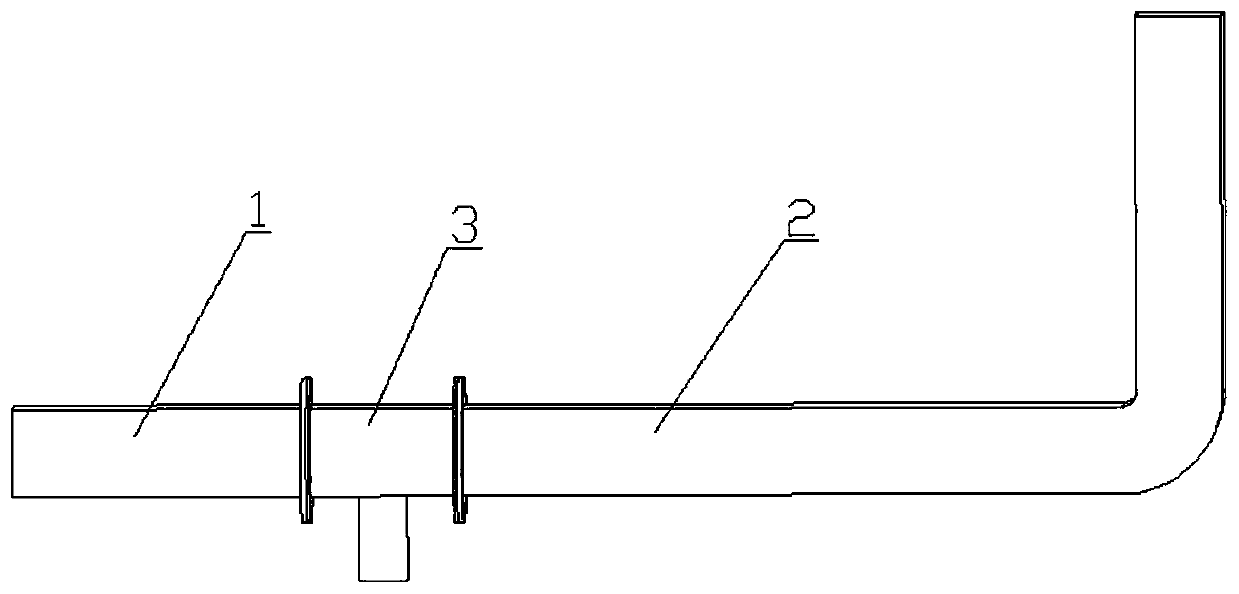

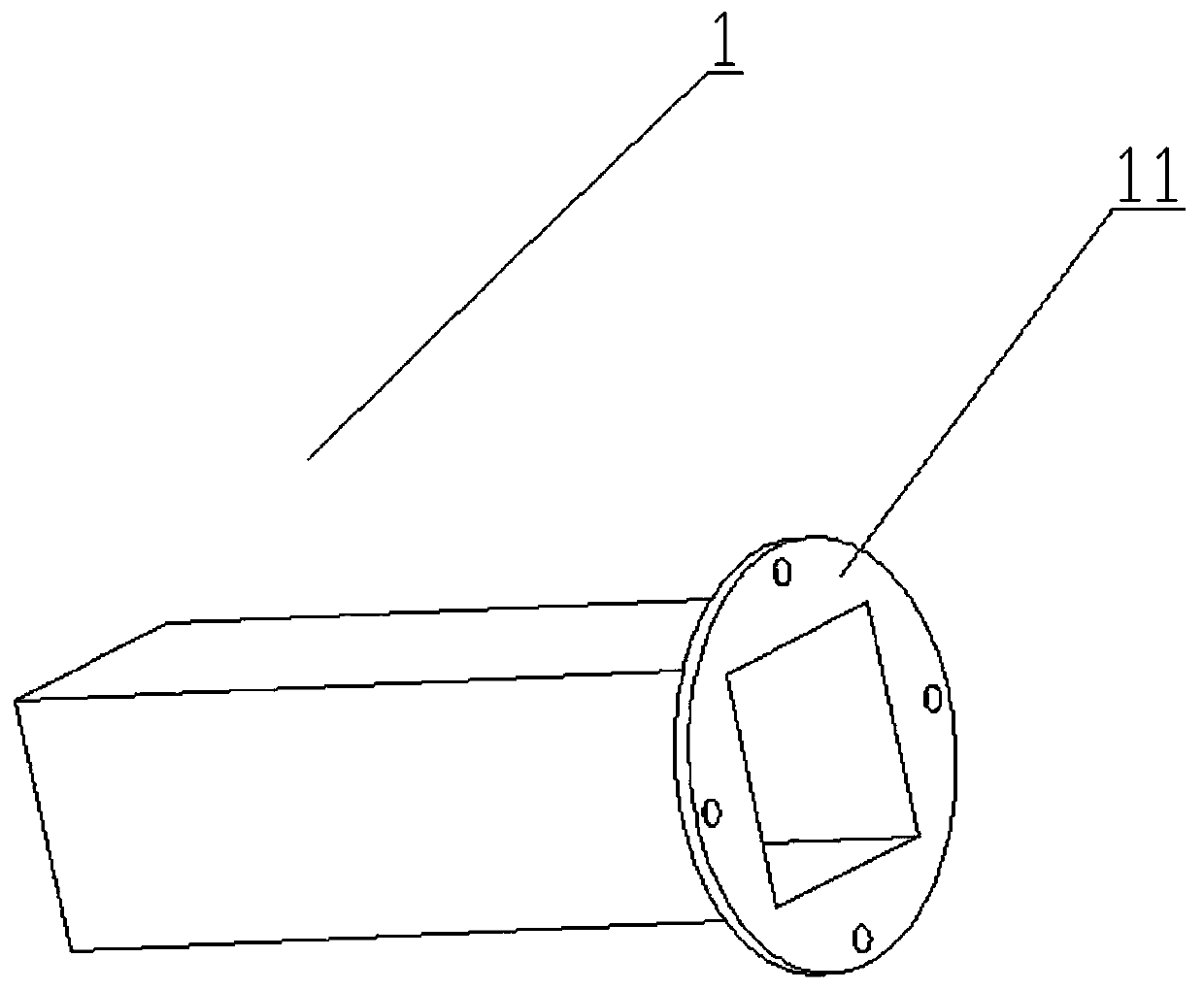

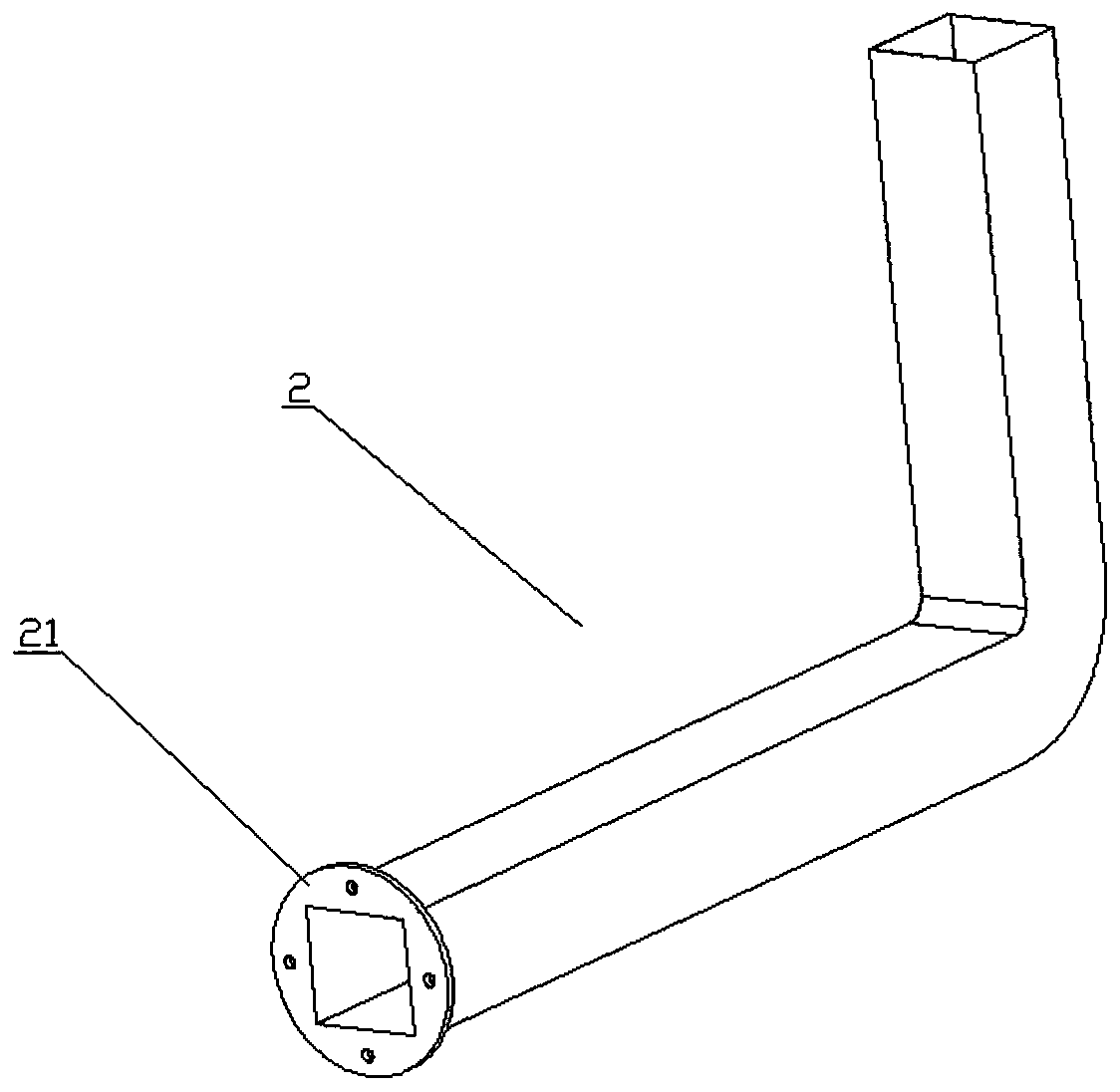

[0032] see figure 1 as well as Figure 4 , an air duct applied to a scrap aluminum baler for cans, including a main air duct 1 and a residual air duct 2, the air duct also includes a crushing device 3, the crushing device 3 includes a conveying pipe 31, and the bottom end of the conveying pipe 31 is provided with waste The aluminum channel 32, the waste aluminum channel 32 includes a feed port and a discharge port. Pressing device 33, extruding device 33 is arranged on the outer side wall of the upper end of conveying pipe 31, and the feeding port of waste aluminum channel 32 is provided with filter screen 35, and filter screen 35 is arranged obliquely in conveying pipe 31, is provided with on the filter screen 35 The dust bag 36 covers the outside of the filter screen 35 .

[0033] see figure 2 , image 3 as well as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com