Optical engine and lengthened piston thereof

A technology for optical engines and pistons, applied to engine components, machines/engines, pistons, etc., can solve problems such as backwardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

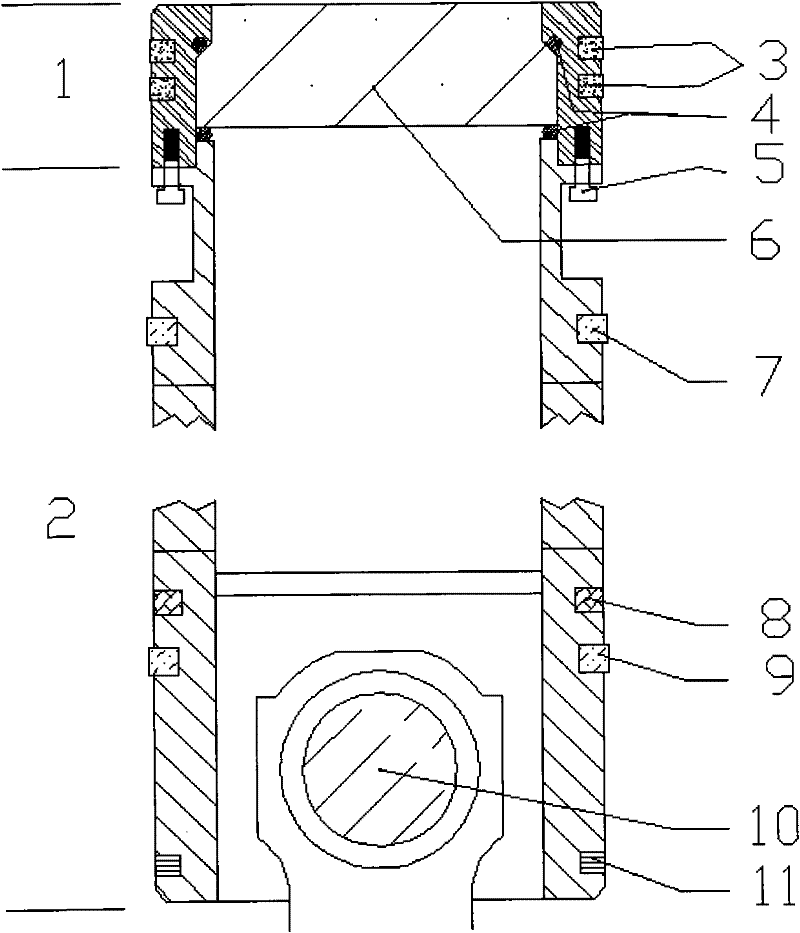

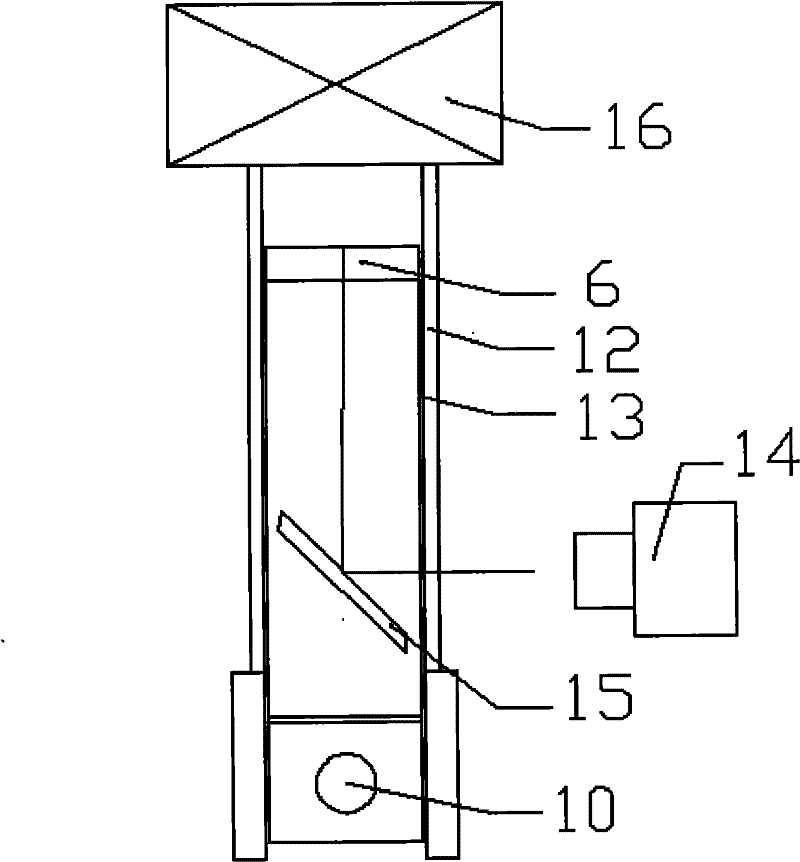

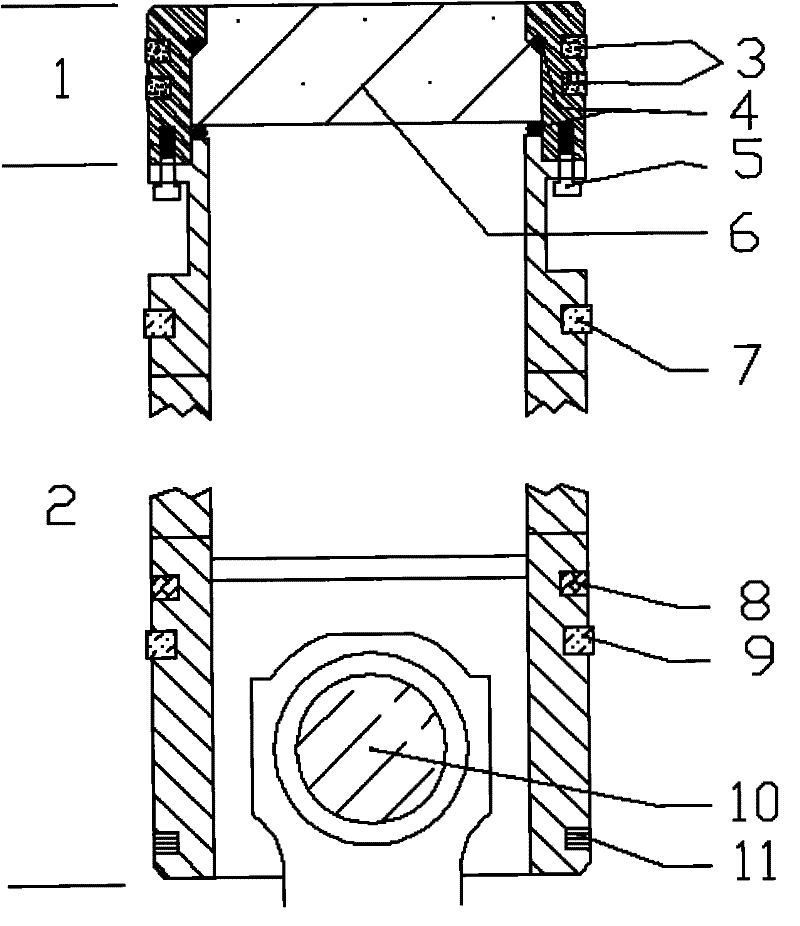

[0025] This embodiment relates to an extended piston of an optical engine, which mainly consists of a piston top window part 1, a piston extended part 2, two sets of piston compression rings 3, two Inconel alloy C-rings 4, bolts 5, a transparent window 6, Lining ring 7,9, oil control ring 8, piston pin hole 10, scraper ring 11, etc. are composed of parts. The piston top window part 1 and the piston extension part 2 of the extended piston are connected by bolts 5, the structure is simple, and the transparent window is easy to disassemble. Simultaneously, two groups of liner rings are arranged on the extended piston to ensure that the extended piston moves vertically along the cylinder liner 12 axes.

[0026] 1. The extended piston 13 is composed of two parts: the window part 1 at the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com