Ice drink bottle mold and method for preparing ice drink bottle

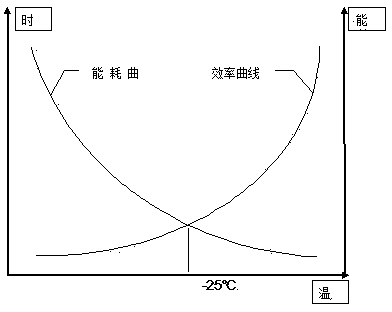

A beverage bottle and mold technology, which is used in ice making, ice making, household appliances, etc., can solve the problems of large bottle body and invalid water quality materials, and achieve the effects of protecting hands, balancing energy consumption costs, and selecting safe and reliable mold materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

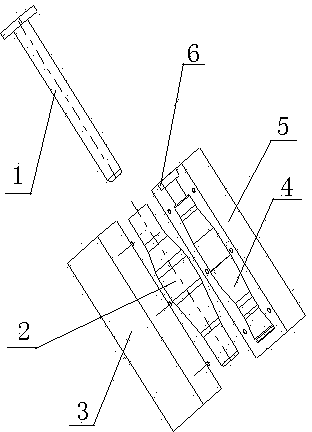

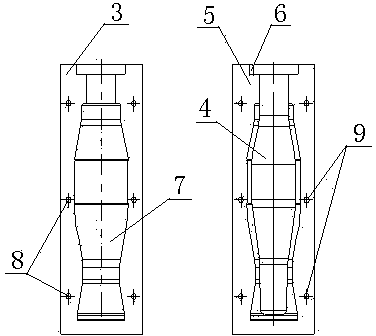

[0031] A beverage bottle mold made of ice, comprising a lower mold 3, an upper mold 5, and a core 2, characterized in that the lower mold 3 is provided with a lower die cavity 7 and a gate, and the upper die 5 is provided with an upper die cavity 4 and riser 6, the core 2 has an axial cylindrical cavity, the T-shaped positioning rod 1 is inserted into the cylindrical cavity, and the core 2 is placed in the lower die after the upper mold 5 and the lower mold 3 are closed. Between the cavity 7 and the upper die cavity 4, the outer surface of the core 2 and the inner wall of the lower die cavity 7 and the inner wall of the upper die cavity 4 form a bottle-shaped cavity with a large middle part and a small upper mouth. 5 communicates with the gate and riser 6 on the lower mold 3.

[0032] The upper mold 5, the lower mold 3 and the core 2 are made of silica gel materials with different hardness; the mold adopts a T-shaped groove to limit the height of the core, and at the same time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com