Bicycle for aloft work

A technology for high-altitude work and bicycles, which is applied to overhead lines/cable equipment, etc., can solve the problems of inconvenient operation and movement, difficult speed control, and difficulty in carrying out operations, and achieves the effect of convenient operation, easy operation, and preventing the car body from rolling away.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

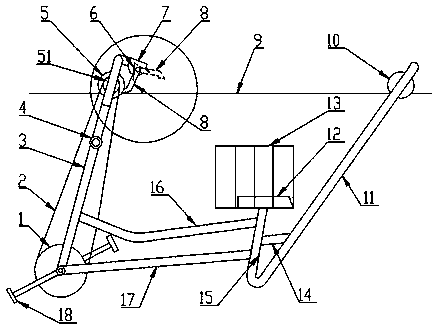

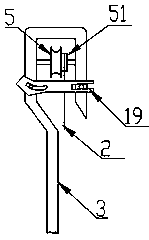

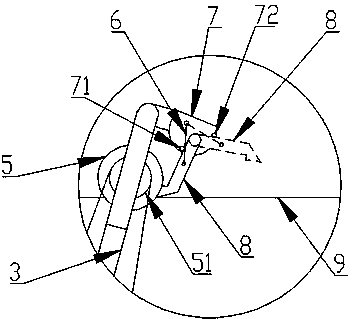

[0035] Aerial work bicycles, such as Figure 1~3 Shown, comprise main beam, seat 12, support forearm 3, support rear arm 11, pedal wheel disc 1, flywheel 51, front roller 5, passive rear roller 10.

[0036] The main beam includes an upper arc beam 16 , a lower straight beam 17 and a vertical beam 15 . The upper arc beam 16 and the lower straight beam 17 are arranged up and down, the upper arc beam 16 is a curved beam with a slight curvature at the front, the lower straight beam 17 is obliquely upward from front to back, the vertical beam 15 is basically vertically arranged, and the vertical beam 15 It is connected to the rear ends of the upper arc beam 16 and the lower straight beam 17. Seat 12 is arranged on the upper end of vertical beam 15, and safety fence 13 is set around seat 12.

[0037] The supporting forearm 3 is connected to the front ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com