Evaporative cooling medium leakage monitoring and treating system

A medium leakage and treatment system technology, which is applied in the field of monitoring and treatment systems, can solve problems that cannot guarantee the personal safety of staff, and does not involve the monitoring and treatment of evaporative cooling medium leakage, so as to reduce operational risks, ensure personal safety, and improve The effect of the factor of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

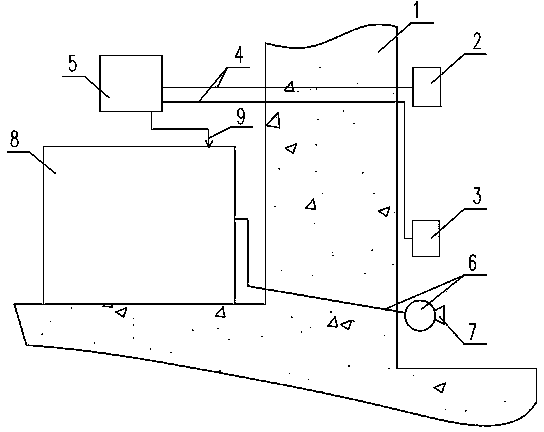

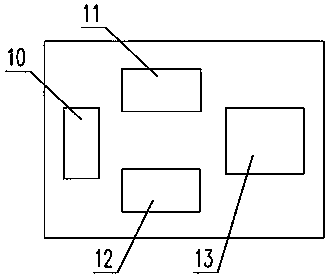

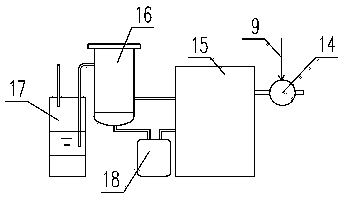

[0040] An evaporative cooling medium leakage monitoring and processing system includes a medium monitoring device and a medium processing device, the medium monitoring device includes an oxygen sampling box 2, a cooling medium sampling box 3, a sampling pipe 4 and a monitoring controller 5, the oxygen sampling box 2 and The cooling medium sampling box 3 is installed on the inner wall of the motor fan cover 1, and the cooling medium sampling box 3 is located below the oxygen sampling box 2; the medium processing device includes a suction nozzle 7, a pipeline 6 and a medium recovery processor 8, and the suction The nozzle 7 is installed in the motor hood 1, and the medium recovery processor 8 is installed outside the motor hood 1, and the suction nozzle 7 is connected with the medium recovery processor 8 through the pipeline 6; the monitoring controller 5 and the medium recovery The processor 8 is connected through a cable 9, and the oxygen sampling box 2 and the cooling medium s...

Embodiment 2

[0043] An evaporative cooling medium leakage monitoring and processing system includes a medium monitoring device and a medium processing device, the medium monitoring device includes an oxygen sampling box 2, a cooling medium sampling box 3, a sampling pipe 4 and a monitoring controller 5, the oxygen sampling box 2 and The cooling medium sampling box 3 is installed on the inner wall of the motor fan cover 1, and the cooling medium sampling box 3 is located below the oxygen sampling box 2; the medium processing device includes a suction nozzle 7, a pipeline 6 and a medium recovery processor 8, and the suction The nozzle 7 is installed in the motor hood 1, and the medium recovery processor 8 is installed outside the motor hood 1, and the suction nozzle 7 is connected with the medium recovery processor 8 through the pipeline 6; the monitoring controller 5 and the medium recovery The processor 8 is connected through a cable 9, and the oxygen sampling box 2 and the cooling medium s...

Embodiment 3

[0048] An evaporative cooling medium leakage monitoring and processing system includes a medium monitoring device and a medium processing device, the medium monitoring device includes an oxygen sampling box 2, a cooling medium sampling box 3, a sampling pipe 4 and a monitoring controller 5, the oxygen sampling box 2 and The cooling medium sampling box 3 is installed on the inner wall of the motor fan cover 1, and the cooling medium sampling box 3 is located below the oxygen sampling box 2; the medium processing device includes a suction nozzle 7, a pipeline 6 and a medium recovery processor 8, and the suction The nozzle 7 is installed in the motor hood 1, and the medium recovery processor 8 is installed outside the motor hood 1, and the suction nozzle 7 is connected with the medium recovery processor 8 through the pipeline 6; the monitoring controller 5 and the medium recovery The processor 8 is connected through a cable 9, and the oxygen sampling box 2 and the cooling medium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com