A method for preparing zinc caseinate by extrusion expansion method

A zinc caseinate, extrusion and puffing technology, applied in the field of zinc caseinate, can solve the problems of incomplete product quality, waste of labor conversion, high labor intensity, etc., and achieve the effects of good viscosity, normal odor, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

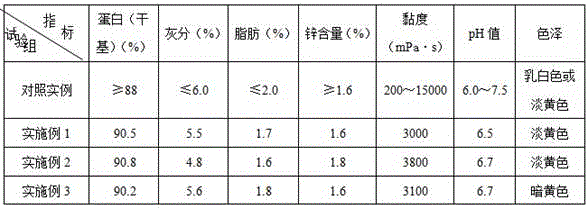

Embodiment 1

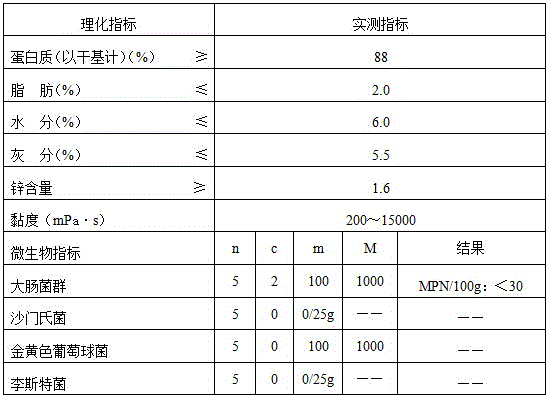

[0024] A method for preparing zinc caseinate by extrusion method, comprising the following steps:

[0025] ① Raw material characteristics: Casein is used as raw material, and the physical and chemical indicators of casein are 92% protein, 1.6% fat, and 1.7% ash;

[0026] ② Preparation of alkaline zinc salt solution: dissolving zinc sulfate in ammonia water to form an alkaline zinc sulfate solution with a mass fraction of 3%;

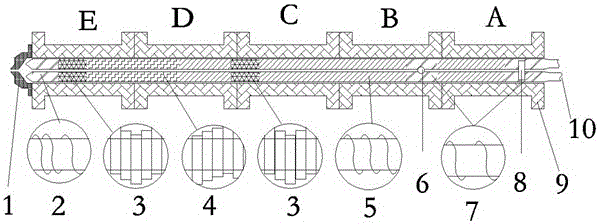

[0027] ③Extrusion and puffing transformation: Add casein into the extruder at a uniform speed, add alkaline zinc sulfate solution at the same time, the amount of alkaline zinc sulfate solution added is 1% of the mass of casein, and the addition of alkaline zinc sulfate solution The flow rate is 200L / h, so that the casein and alkaline zinc sulfate solution are extruded and expanded in the extruder to obtain zinc caseinate, wherein the casein and alkaline zinc sulfate solution pass through five The temperature section is transformed, the temperature of se...

Embodiment 2

[0030] A method for preparing zinc caseinate by extrusion method, comprising the following steps:

[0031] ① Raw material characteristics: Casein is used as raw material, and the physical and chemical indicators of casein are 92.4% protein, 1.6% fat, and 2.0% ash;

[0032] ② Preparation of alkaline zinc salt solution: dissolving zinc oxide in a sodium hydroxide solution with a mass fraction of 10% to form an alkaline zinc oxide solution with a mass fraction of 1%;

[0033] ③ Extrusion and puffing conversion: Add casein into the extruder at a uniform speed, and add alkaline zinc oxide solution at the same time, the amount of alkaline zinc oxide solution added is 4% of the mass of casein, and the amount of alkaline zinc oxide solution is The amount of addition is 400L / h, and the casein and the alkaline zinc oxide solution are extruded and expanded in the extruder to obtain zinc caseinate, wherein the casein and the alkaline zinc oxide solution are sequentially passed through fiv...

Embodiment 3

[0036] A method for preparing zinc caseinate by extrusion method, comprising the following steps:

[0037] ① Raw material characteristics: Casein is used as raw material, and the physical and chemical indicators of casein are 92.4% protein, 2.5% fat, and 2.0% ash;

[0038] ② Preparation of alkaline zinc salt solution: dissolving zinc oxide in a sodium hydroxide solution with a mass fraction of 10% to form an alkaline zinc oxide solution with a mass fraction of 2%;

[0039] ③Extrusion and puffing conversion: Add casein into the extruder at a uniform speed, and add alkaline zinc oxide solution at the same time, the amount of alkaline zinc oxide solution added is 3% of the mass of casein, and the amount of alkaline zinc oxide solution is The amount of addition is 400L / h, and the casein and alkaline zinc oxide solution are extruded and expanded in the extruder to obtain zinc caseinate, wherein the casein and alkaline zinc oxide solution are sequentially passed through the extruder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com