Large cast steel long cylindrical piece feeding process method

A process method and a long tube technology, which are applied in the field of feeding technology of large cast steel long tubes, can solve the problems of weakened sequential solidification, increased processing costs, and shrinkage porosity, so as to reduce the workload of gas cutting, reduce processing costs, and improve Intrinsic Quality Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

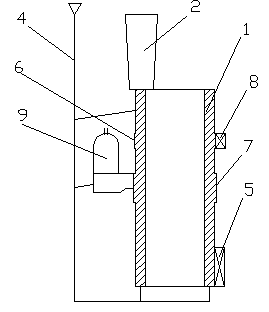

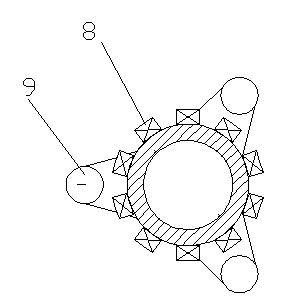

[0013] like figure 1 As shown, a large-scale cast steel long tube feeding process method is carried out as follows: the large-scale cast steel long tube 1 is cast, and is divided into two independent feeding zones in the axial direction, which are respectively the upper feeding zone and the lower feeding area, the upper feeding area adopts open riser 2 feeding, and the boundary of each adjacent independent feeding area is formed by cutting off the outer cold iron 8 to form a cold iron end area, which is self-feeding; The above-mentioned lower feeding area is fed by the side riser 9, and the outer chill iron 5 at the end of the lower feeding area shields the overheating effect of the bottom return pouring, so as to extend the feeding distance.

[0014] The design parameters of open riser 2 are:

[0015] Let the casting height be h and the outer diameter be d;

[0016] When h / d≥4, the open riser 2 is designed as an annular riser;

[0017] When h / d<4, the open riser 2 is desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com