Manufacturing method of casting mold for steel casting forming process

A technology of molding process and manufacturing method, which is applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of poor surface finish of castings, easy formation of sticky sand, and easy damage of sand molds, so as to save the weight of blanks and save models. Cost, Effect of Guaranteed Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

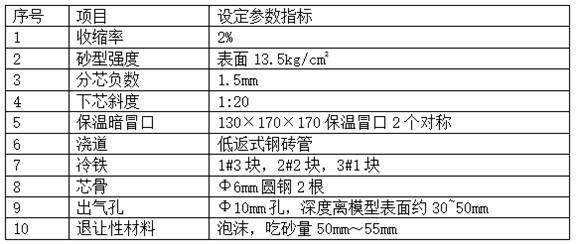

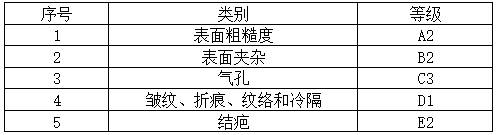

[0033] use as figure 1 The manufacturing method of a steel casting forming process casting mold shown in the figure uses furan resin sand molding to produce product model: ZB2.5-75-001-MP, name: rear bearing body, material: 35CrMo steel casting product 15 pieces, it includes the following steps:

[0034] Step 1. Three-dimensional process modeling: Designers use SolidWorks three-dimensional modeling software to carry out three-dimensional process modeling on the casting process of steel castings. The basic process elements of the three-dimensional process model include shrinkage rate, self-hardening resin sand core Negative number, lower core slope, machining allowance, pouring system, cold iron, core bone, air outlet and concession materials, when the casting mold of steel castings needs to be formed by sand mold and multiple sand cores, it is necessary to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com