A kind of feeding mechanism and sewing machine

A technology of feeding mechanism and machine needle, which is applied to cloth feeding mechanism, sewing machine components, needle seat for sewing machine, etc., can solve the problems of high use cost and complex structure, and achieve the effect of low cost, simple mechanical structure and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

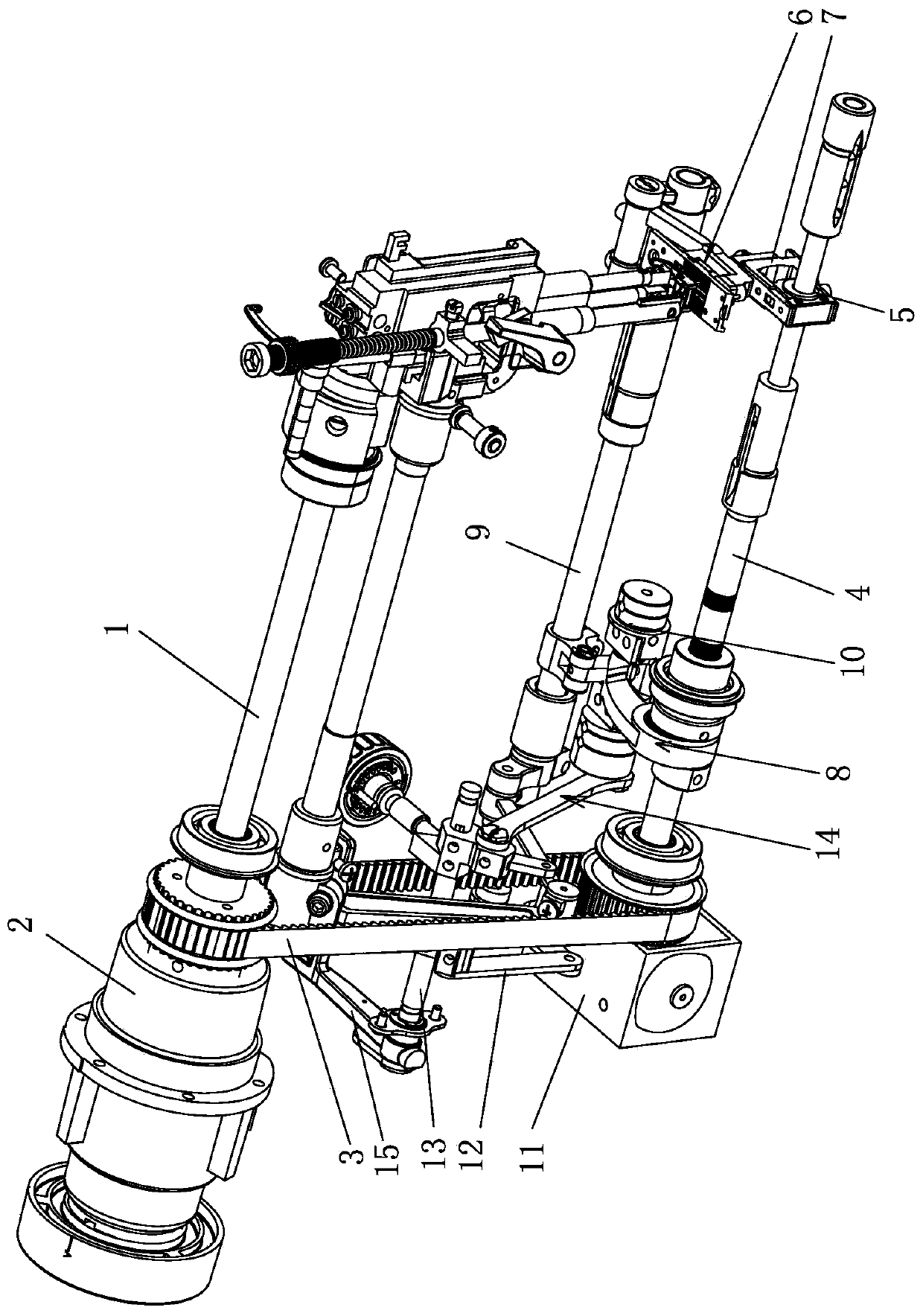

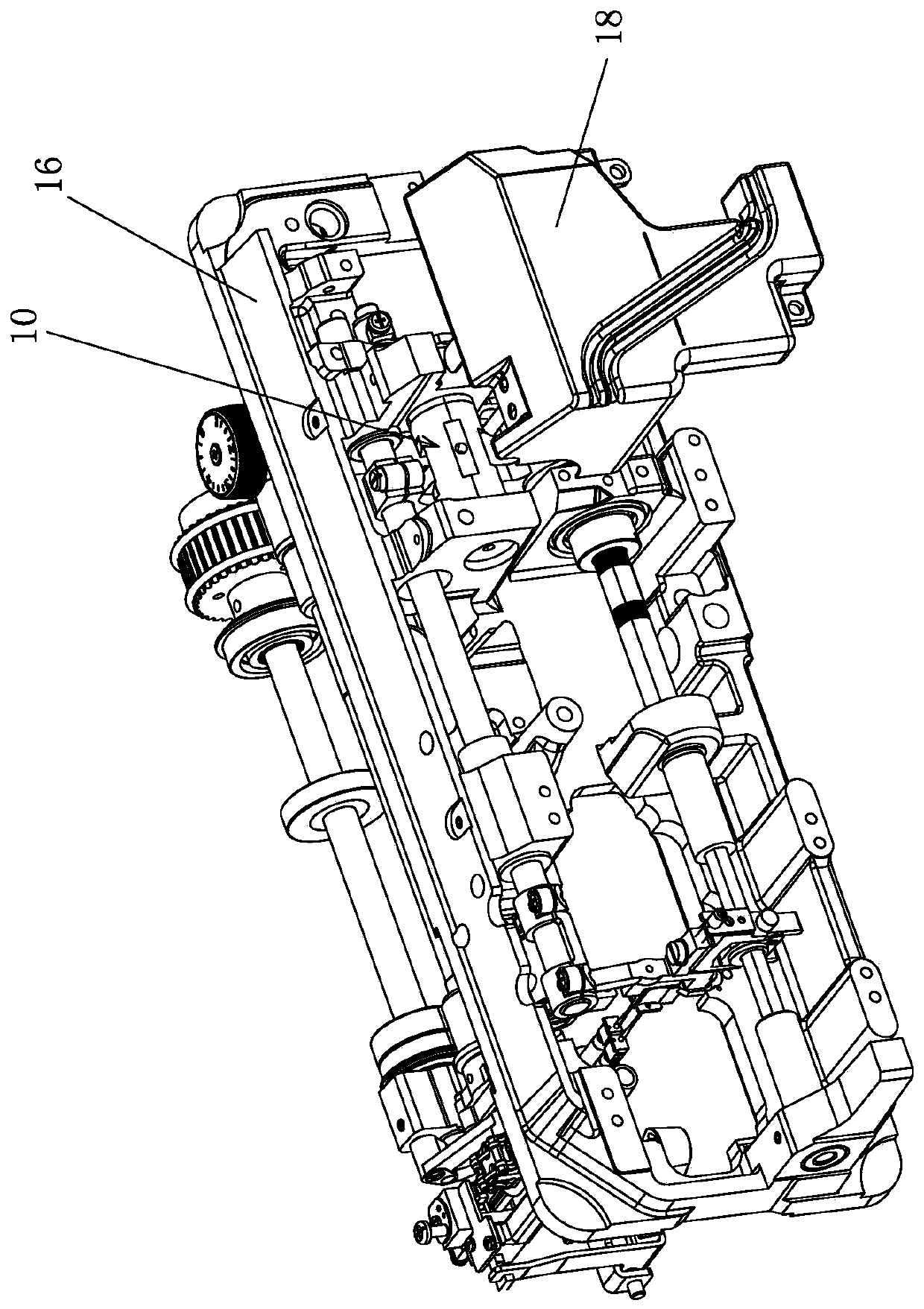

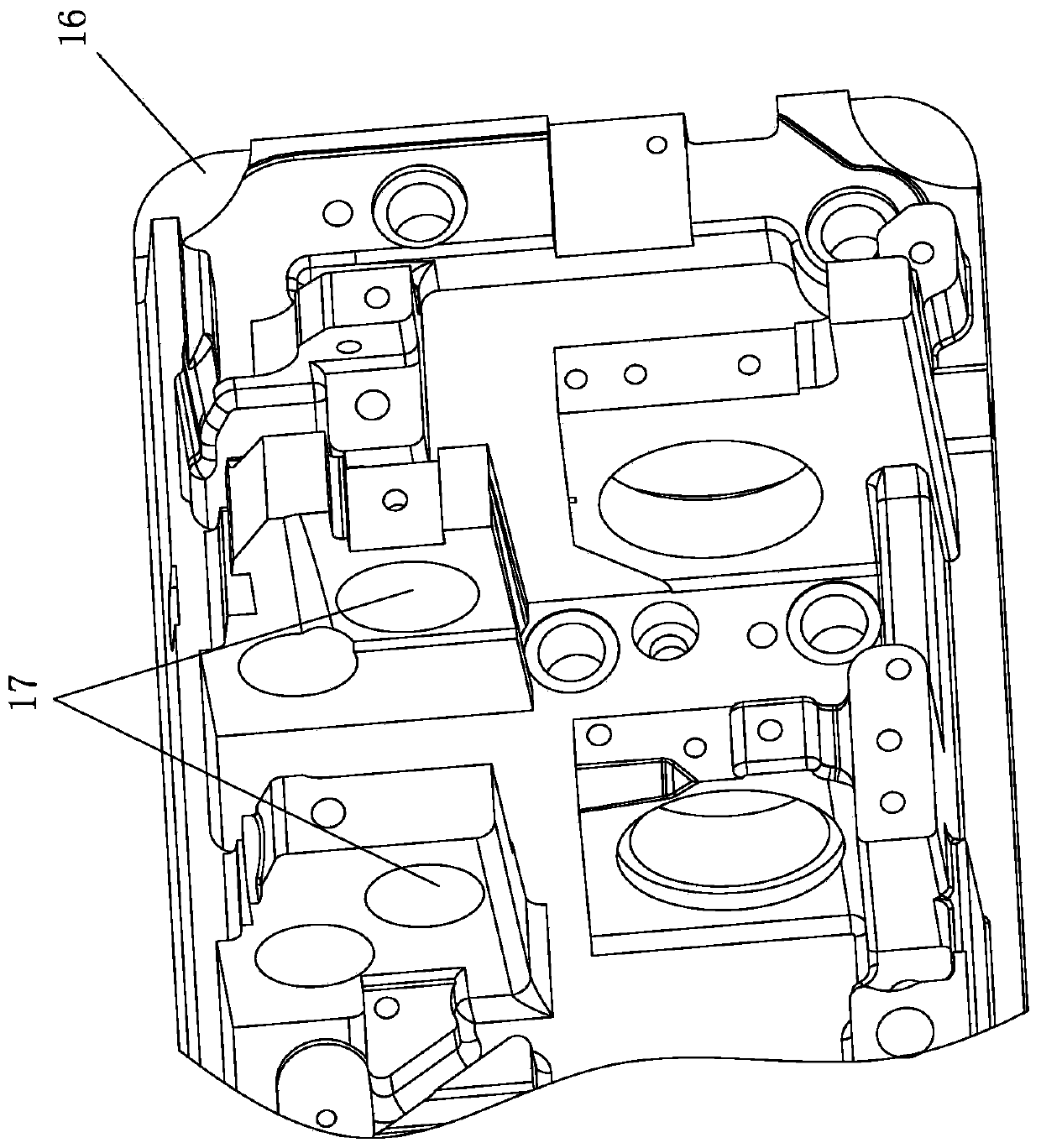

[0034] Such as Figure 4 shown. A feeding mechanism, comprising a needle bar support swing shaft 20, an upper shaft 30, and a lower shaft 40, one end of the needle bar support swing shaft 20 is connected to a motor through a connecting rod assembly, and the other end is provided with a needle bar support 50, the needle At least two needle bars 60 are arranged on the bar support 50, and when the multi-needle machine is used, the number of needle bars 60 increases accordingly. This embodiment takes a double-needle machine as an example. Therefore, there are two needle bars 60, and the two machine needles 70 are respectively arranged on the corresponding two needle bars 60. The motor drives the swing shaft 20 of the needle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com