Preparation method of environment-friendly plate of building

A construction and board technology, applied in the field of environmental protection board preparation for construction, can solve the problems of subdividing difficult waste into various raw materials, a lot of manpower and financial resources, and inability to fully utilize domestic waste, and achieve high market economic value and social Value, high recycling rate, clear effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

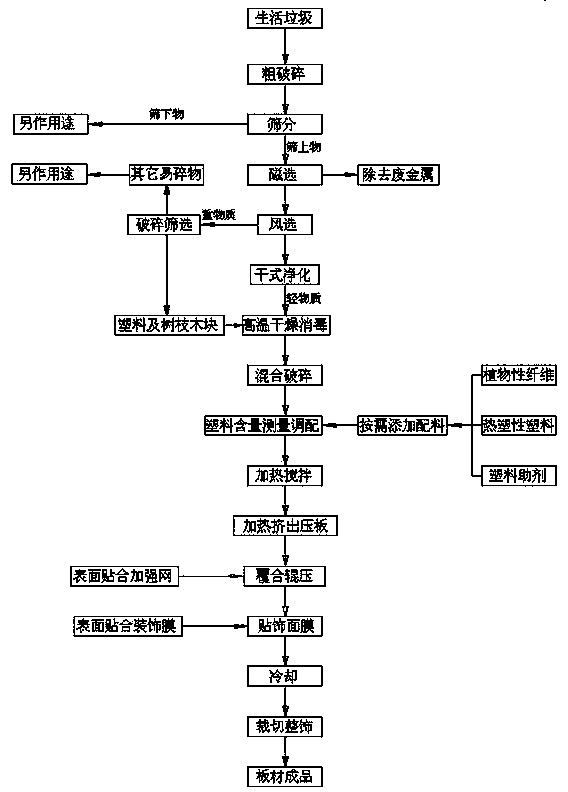

[0029] see figure 1 As shown, the preparation method of environmental protection boards for buildings is to use waste plastics, waste rubber, waste furniture, waste textiles, branches, leaves, paper, grass, and waste wood that are sorted out of municipal solid waste as the main raw materials. Plate, wherein, comprises the steps:

[0030] (1) Coarse crushing and sorting treatment, sending waste plastics, waste rubber, waste furniture, waste textiles, branches, leaves, paper, grass, and waste wood into the coarse crusher, which performs primary crushing Finally, coarsely crushed raw materials with a particle size of 0 to 20 cm are obtained; the coarsely crushed raw materials enter the first rolling sieve for rolling screening to obtain the oversize with a particle size greater than 6 to 8 cm and the undersize with a particle size of less than 6 to 8 cm. The oversize material is transferred to the direction of the magnetic separator and wind separator in sequence; the magnetic s...

Embodiment 2

[0043] see figure 1 As shown, the difference from Embodiment 1 is that, between step (1) and step (2) of Embodiment 1, a step of crushing and sorting the heavy materials is further included. This is due to the selection of light and heavy substances by wind selection, and the composition of heavy substances mainly includes tough substances such as block thermoplastics, rubber, textiles, branches and wood blocks, and also includes a small part of particles with a particle size greater than 6-6. 8cm glass, sand, kitchen waste and other fragile substances; it can be seen that there are still a lot of thermoplastics and vegetable fibers in the heavy substances. In order to make full use of this part of the waste resources, further crushing and screening are needed to remove the fragile substances. However, the steps of the medium crushing and sorting treatment of the heavy materials include: conveying the heavy materials to the medium crusher for secondary crushing, and passing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com