Method for first ironing and then printing of cigarette packet

A technology of ironing first and then printing cigarette packs, which is applied in the field of cigarette packs being stamped first and then printed, which can solve the problems of not being able to meet the requirements of high-end cigarette packs, low positioning accuracy, and aluminum powder loss, etc., to achieve bright colors and good product molding Good performance, no effect of dropping dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention provides a method for printing cigarette packs after ironing. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

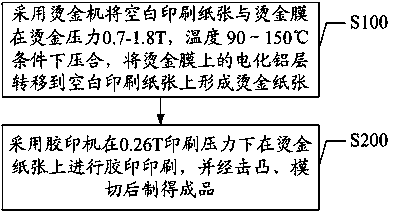

[0021] Such as figure 1 Shown is a method of printing cigarette packs after first ironing, wherein the method includes the following steps:

[0022] S100. Use a hot stamping machine to press the blank printing paper and the hot stamping film under the conditions of a hot stamping pressure of 0.7-1.8T and a temperature of 90-150°C, and transfer the anodized aluminum layer on the hot stamping film to the blank printing paper to form a hot stamping paper.

[0023] Wherein, the hot stamping machine is Yahua 920 hot stamping machine, the hot stamping pressure is 1.1T,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com