Folding-lifting type movable small-scale portal crane

A gantry crane and mobile technology, applied in the direction of trolley cranes, cranes, hoisting equipment braking devices, etc., can solve the problem of floor space, initial construction cost, plant occupation cost, high maintenance and repair cost, waste of manpower, financial resources, etc. Issues such as increasing the risk of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The crane described in the present invention includes a lifting part, a shaft fixing part and a rotating support part.

[0027] The lifting part can be fixed on the shaft fixing part, the fixed position is adjustable in the vertical direction, and the fixing method is a detachable connection, so as to realize the adjustment of the lifting part in the vertical direction. The lifting part includes a The heavy equipment lifts the object to be lifted; the fixed shaft part is connected with the rotating support part, and the rotating support part can rotate in the horizontal plane with the fixed shaft part as an axis.

[0028] When the lifting part is working, it is raised and fixed along the fixed part of the shaft to complete the lifting work at a suitable height. When it is not working, it is lowered to the bottom along the fixed part of the shaft to save space; the rotating support part When working, it can be unscrewed in the horizontal plane to provide good support for...

Embodiment 2

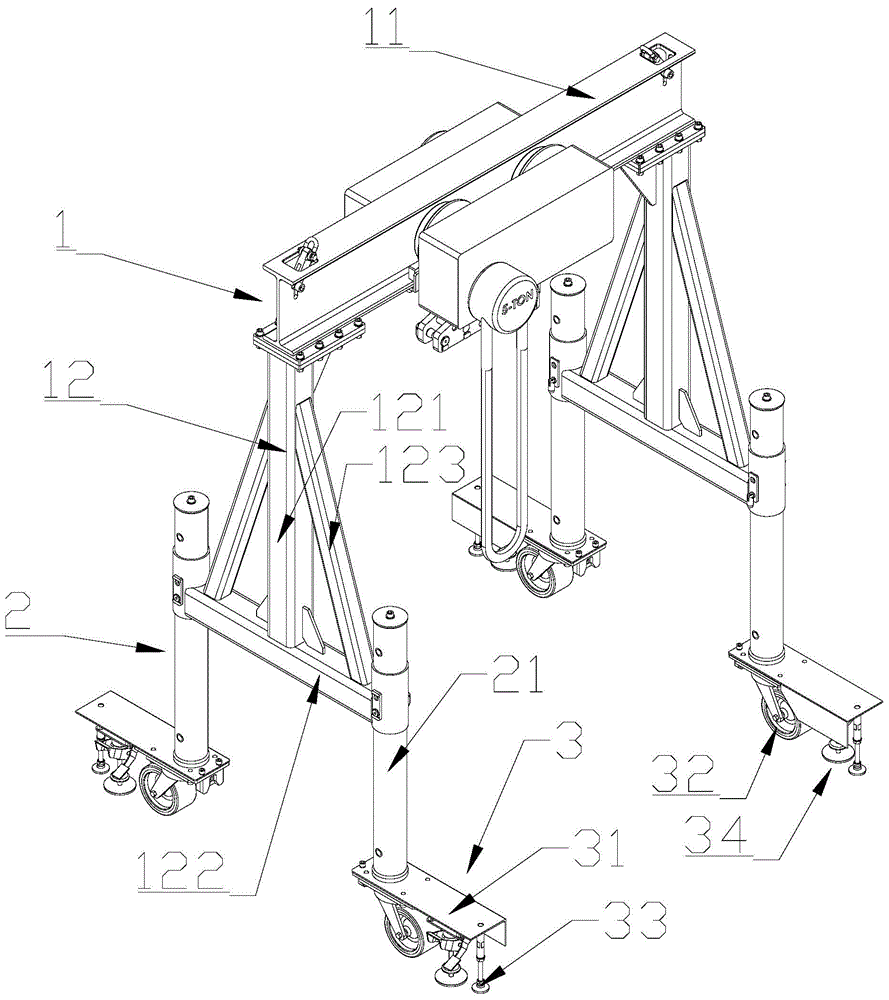

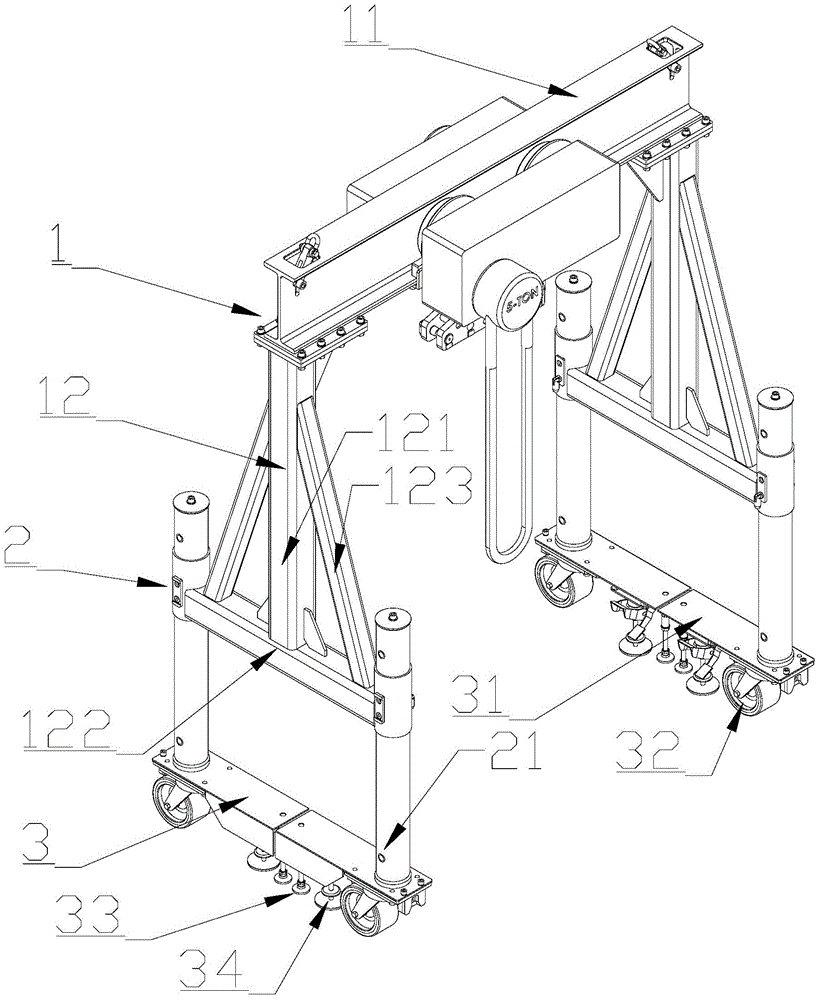

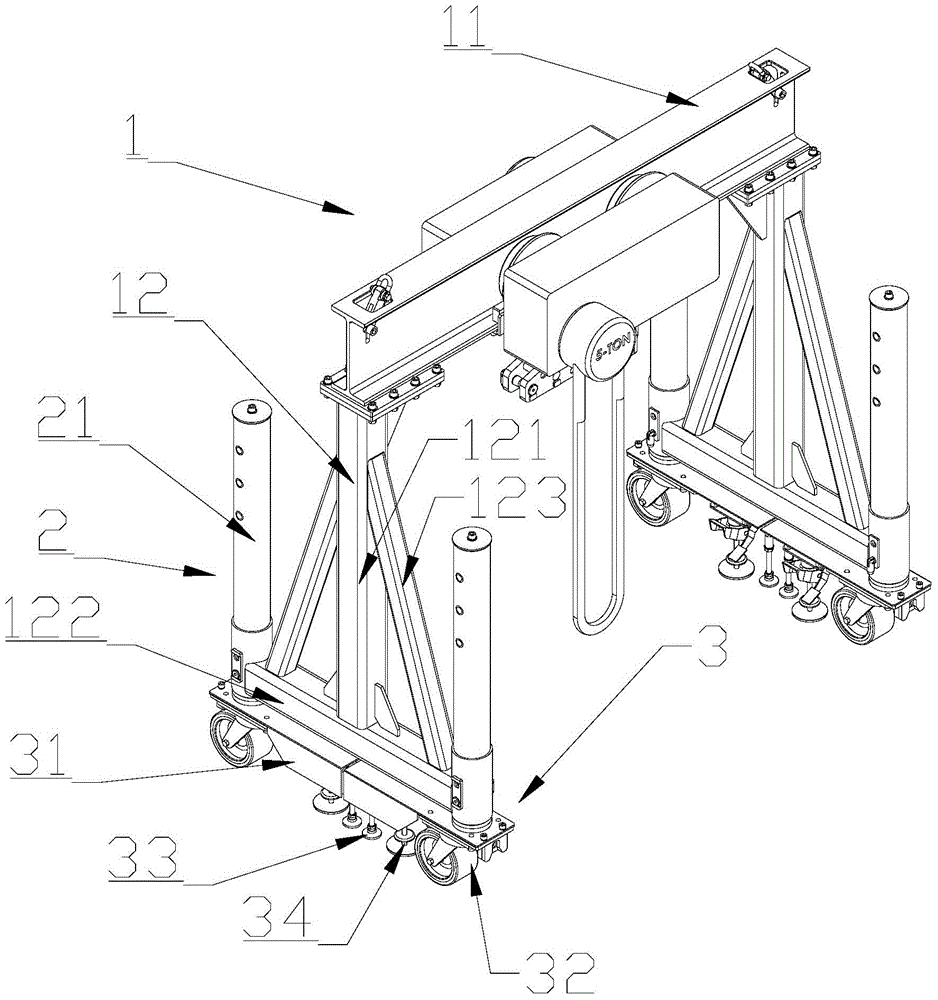

[0030] see figure 1 As shown, it is a schematic structural diagram of the working state of Embodiment 2 of a foldable and lifting mobile small-sized gantry crane of the present invention. In this embodiment, it includes a shaft fixing part 2, a lifting part 1 and a rotating support Part 3, the fixed part 2 includes two sets of lifting legs 21, each group includes two lifting legs 21, the lifting legs 21 are vertically arranged; the lower end is connected with the rotating support part 3, the The rotating support part 3 can rotate around the lifting leg 21 in the horizontal plane to realize the opening and retracting of the rotating supporting part 3; the lifting part 1 is flexibly connected with the fixed shaft part 2 and can be fixed along the fixed Part 2 Ascend and Descend.

[0031] In this embodiment, the number of lifting legs 21 is two groups, four in total. In practical applications, the number of groups of lifting legs 21 and the number of each group can be adjusted a...

Embodiment 3

[0043] Embodiment 3 is similar to Embodiment 2, except that the lifting equipment in Embodiment 2 is an electric hoist, which can provide a more accurate lifting height and save manpower.

[0044]In Embodiment 3, there are three groups of side support parts, correspondingly, there are three groups of lifting legs, and the number of optional support parts is six, so that the beam is divided into two relatively independent spaces, which can Two sets of lifting devices are provided, which are electric hoists in this embodiment, which improves the flexibility of use of the equipment.

[0045] Electric hoists can also be replaced with lifting equipment such as air hoists.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com