A method for producing sodium sulfite by desulfurizing flue gas by double alkali method

A technology of sodium sulfite and double alkali method, which is applied in the field of environmental management and industrial production, can solve problems such as blockage, and achieve the effects of good economic benefits, easy large-scale, and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

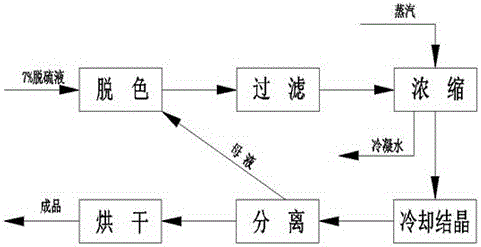

Image

Examples

Embodiment 1

[0019] Using sodium hydroxide solution as a desulfurizer to react with sulfur dioxide in flue gas to prepare sodium sulfite, the preparation process is:

[0020] (a) Add sodium hydroxide solution to increase the pH value of the desulfurization circulating fluid from 5 to 6 to 8. One can increase the desulfurization efficiency from 90% to about 97%; the other is to inhibit the formation of NaHSO 3 The direction of the side reaction is carried out so that it can generate Na as much as possible 2 SO 3 ; The third is to avoid acidic water corrosion.

[0021] (b) Draw out part of the desulfurization circulating liquid, enter the decolorization kettle to decolorize and absorb impurities, and add a strong reducing agent at the same time to make Na 2 SO 4 reduction;

[0022] Lead out 5-8% of the circulating fluid from the outlet of the circulating pump, enter the decolorization tank, control the temperature at 67°C, add 3% activated carbon for decolorization, and further absorb d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com