Preparation method of superlattice energetic material

A superlattice and target technology, applied in the growth of polycrystalline materials, nanotechnology for materials and surface science, chemical instruments and methods, etc., can solve the problems of energy release in reactions and loss of energy-containing properties, and achieve enhanced environmental Adaptability and storability, broad application prospects, effect of improving mass transfer distance and structural uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

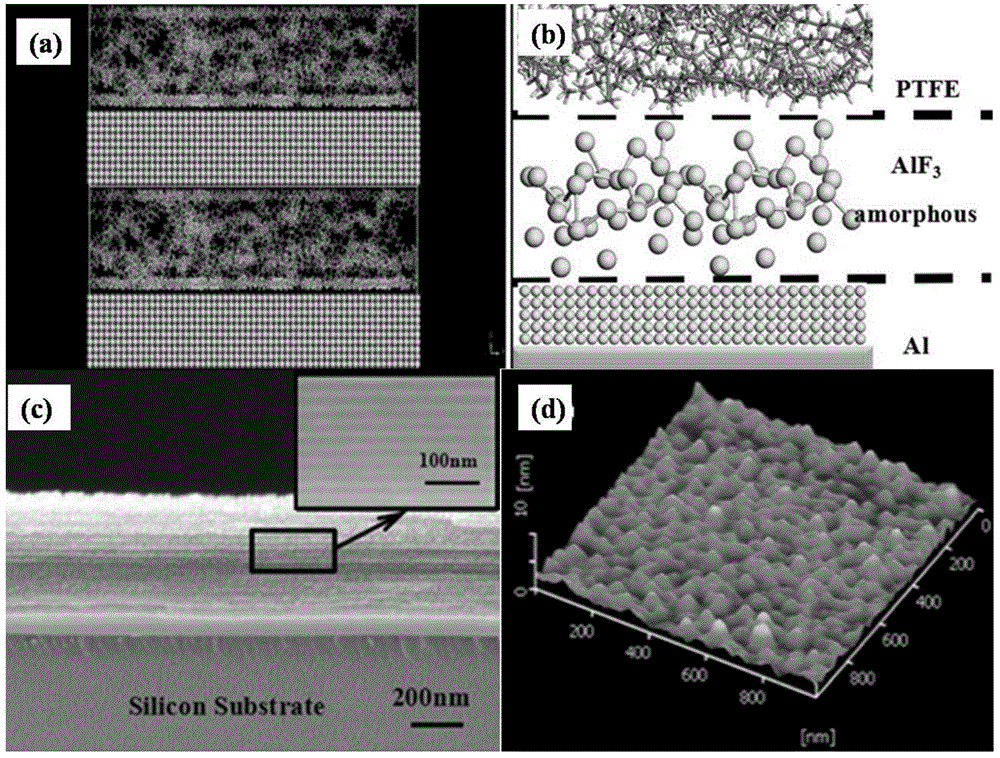

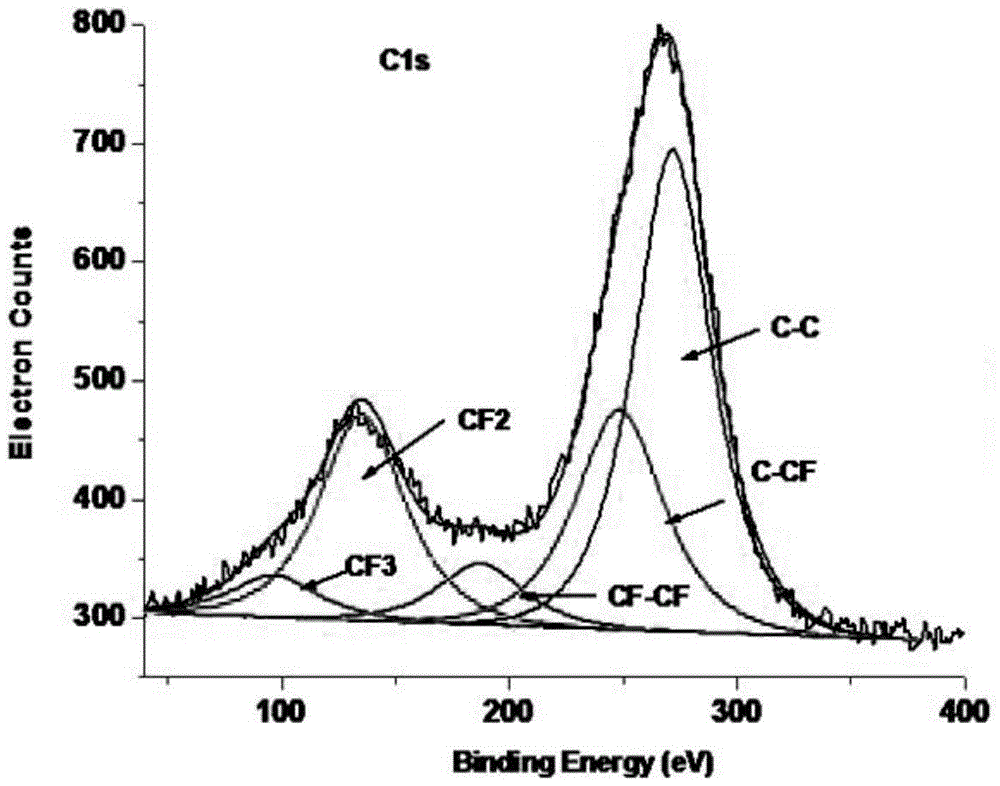

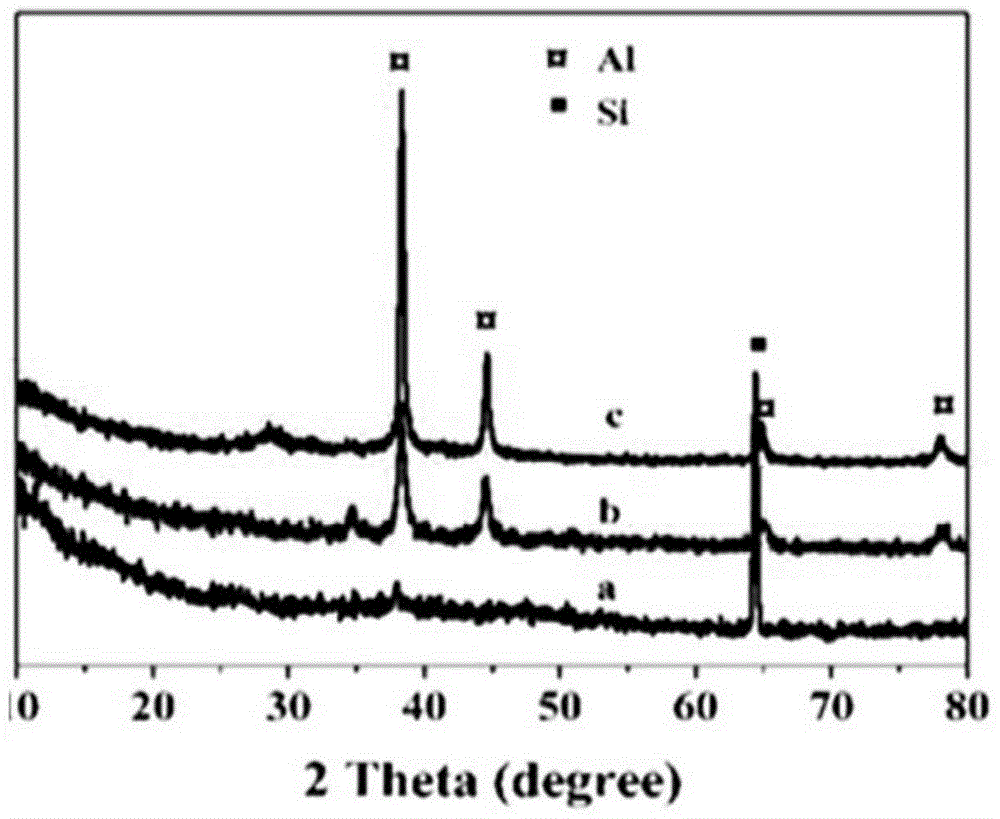

Embodiment 1

[0033] The silicon substrate was ultrasonically washed in acetone for 20 minutes, washed 5 times in water, dried, and then installed on the coating sample stage in the RF magnetron sputtering chamber, turned on the RF magnetron sputtering system, and then installed the PTFE target and Al target To the two RF target positions in the RF magnetron sputtering chamber, adjust the vacuum of the system to 1×10 -4 Pa, argon gas with a purity of 99.9999% is introduced, and the volume flow rate of argon gas is 200 SCCM. Sputter the PTFE target and Al target for 5 minutes to remove dirt and impurities, and then sputter the PTFE target with a sputtering power of 100W for 5 minutes. First, a layer of PTFE nanomembrane with a thickness of less than 10nm is formed on the silicon substrate, and then Sputter the Al target at 100W for 5 minutes to form a layer of Al target nano-film with a thickness of less than 10nm on the PTFE nano-film. Sputter again to form a layer of PTFE nano-film on the Al...

Embodiment 2

[0035] The silicon substrate was ultrasonically washed in acetone for 25 minutes, washed 4 times in water, dried, and then installed on the coating sample stage in the RF magnetron sputtering chamber, turned on the RF magnetron sputtering system, and then installed the PTFE target and Al target To the two RF target positions in the RF magnetron sputtering chamber, adjust the system vacuum to 1×10 -4 Pa, argon with a purity of 99.9999% is introduced, and the volume flow of argon is 250 SCCM. Sputter the PTFE target and Al target for 10 minutes to remove dirt and impurities, and then sputter the PTFE target with a sputtering power of 50W for 10 minutes. First, a layer of PTFE nanofilm with a thickness of less than 10nm is formed on the silicon substrate. 50W sputtering Al target for 10 minutes, forming a layer of Al target nanofilm with a thickness of less than 10nm on the PTFE nanofilm, sputtering again to form a layer of PTFE nanofilm on the Al target, repeating this cycle proce...

Embodiment 3

[0037] The silicon substrate was ultrasonically washed in acetone for 25 minutes, washed 3 times with water, dried, and then installed on the coating sample stage in the RF magnetron sputtering chamber, turned on the RF magnetron sputtering system, and then installed the PTFE target and Mg target To the two RF target positions in the RF magnetron sputtering chamber, adjust the system vacuum to 1×10 -4 Pa, argon with a purity of 99.9999% is introduced, and the volume flow of argon is 250 SCCM. Sputter the PTFE target and Mg target for 10 minutes to remove dirt and impurities. Sputter the PTFE target with a sputtering power of 30W for 20 minutes. First, a layer of PTFE nanomembrane with a thickness of less than 10nm is formed on the silicon substrate. 30W sputtering the Mg target for 20 minutes, forming a layer of Mg target nanofilm with a thickness of less than 10nm on the PTFE nanofilm, sputtering again to form a layer of PTFE nanofilm on the Mg target, repeating this cycle proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com