Inflaming retarding piece of explosion-proof valve

A technology of explosion-proof valves and discs, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of airflow direction, local channel airflow accumulation, pressure increase, etc., to reduce pressure, increase distance, and improve utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

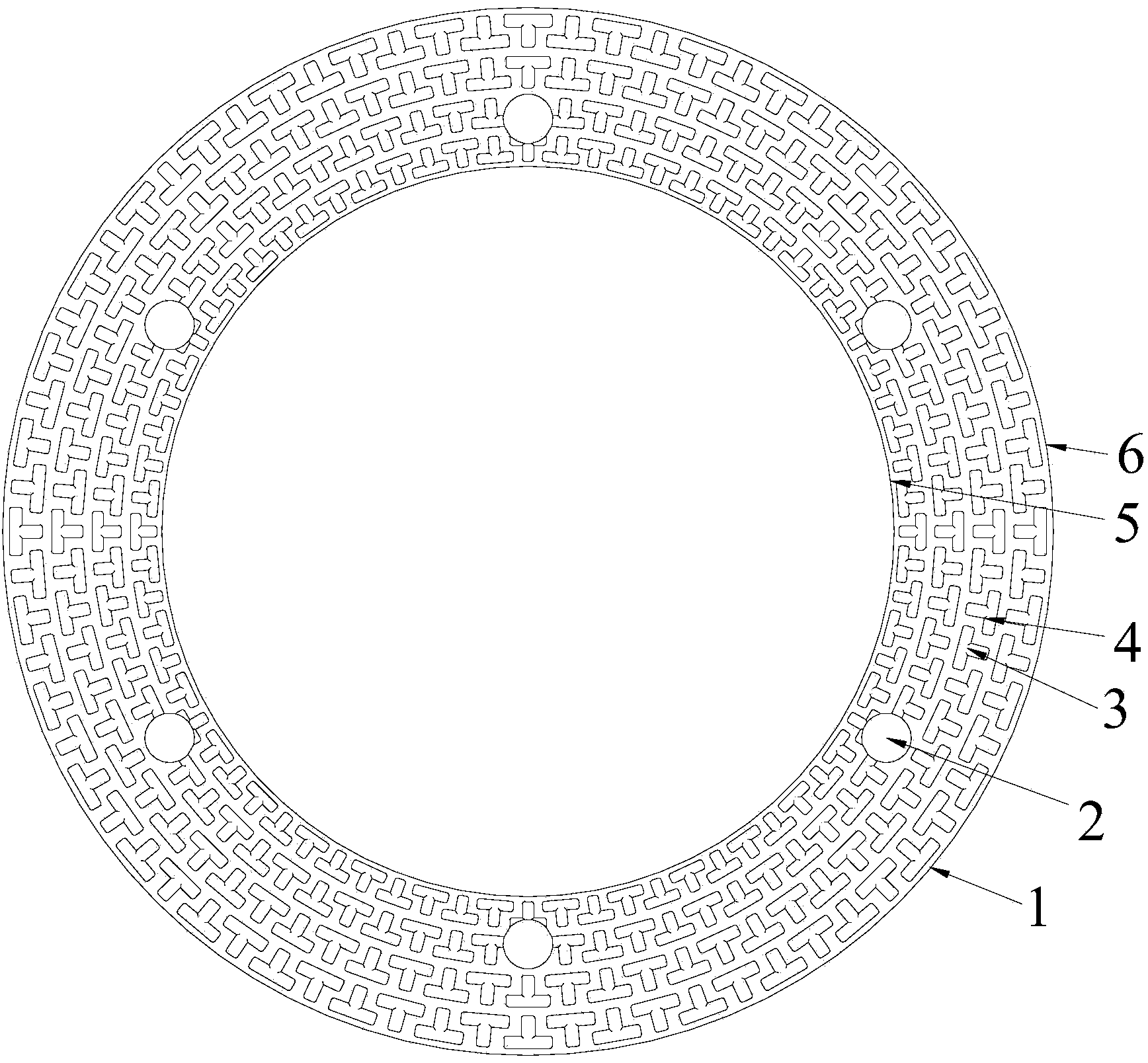

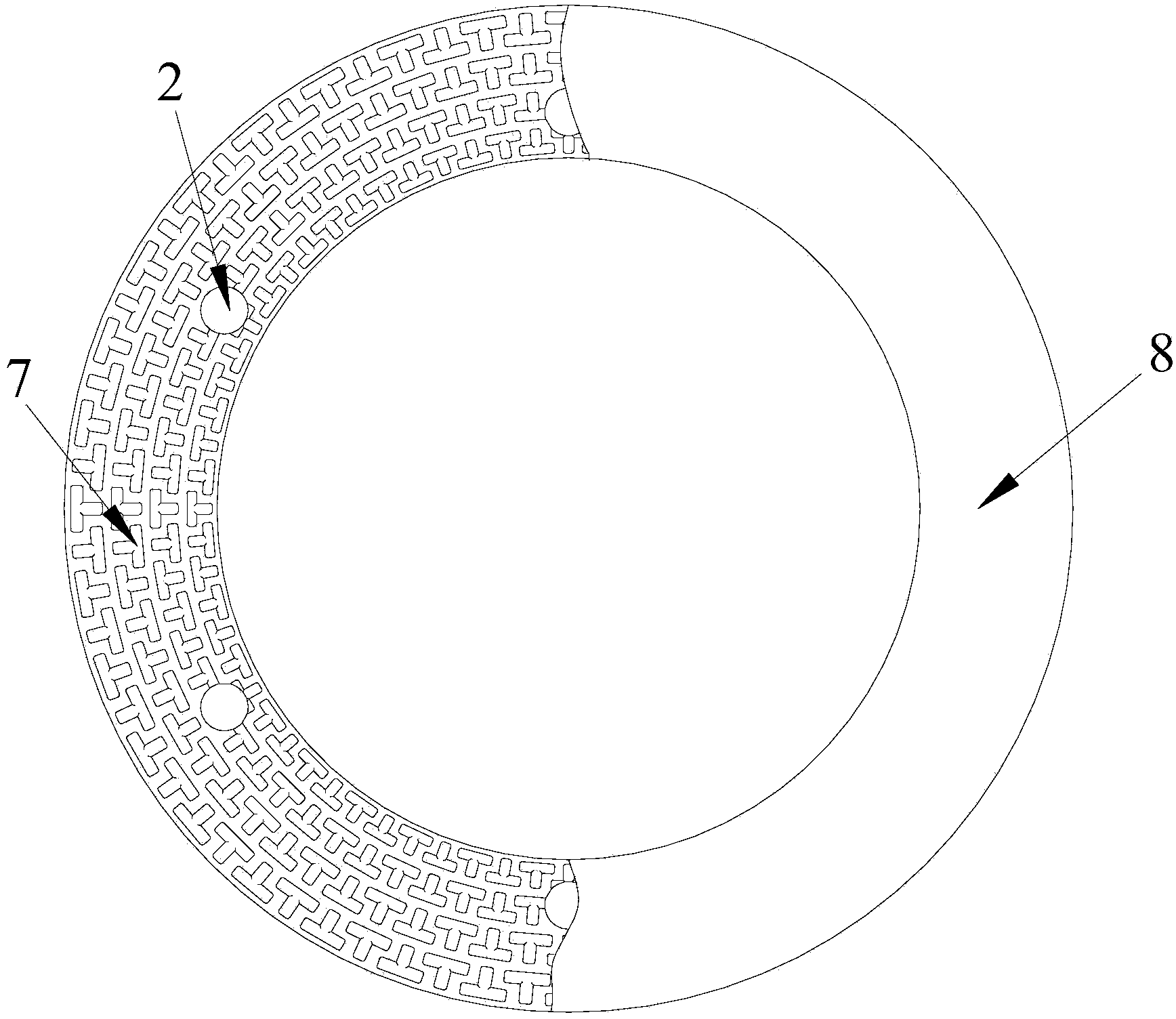

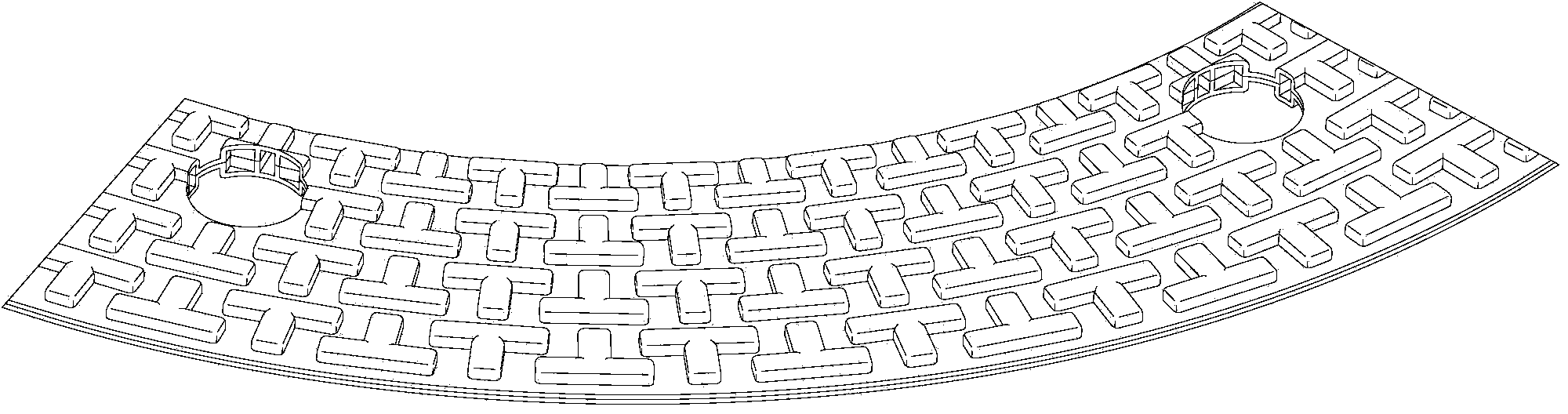

[0033] The present invention comprises: a ring-shaped sheet body 1, with installation holes 2 arranged on the sheet body 1, a number of bosses 7 distributed on the front of the sheet body 1, the bosses 7 are T-shaped structures, and the bosses 7 are evenly distributed along the circumferential direction , the boss 7 is provided with at least two turns, if four turns are provided, the gap between the adjacent bosses 7 forms an airflow channel with multiple bends, the sheet body 1 is an annular sheet metal part, and the boss 7 is It is formed by stamping from the reverse side of the sheet body 1 to the front side, that is, the flame retardant sheet is a stamped part.

[0034] as attached figure 1 to attach Figure 4 As shown, it is Embodiment 1 of the present invention. The bosses 7 of different circles on the sheet body 1 are arranged side by side in the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com