Labor-saving rotary power transmission device

A technology of transmission device and rotating power, applied in the direction of transmission device, gear transmission device, belt/chain/gear, etc., can solve the problems of reducing efficiency, wasting work and time, etc., and achieve the effect of reducing operating costs and saving power energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

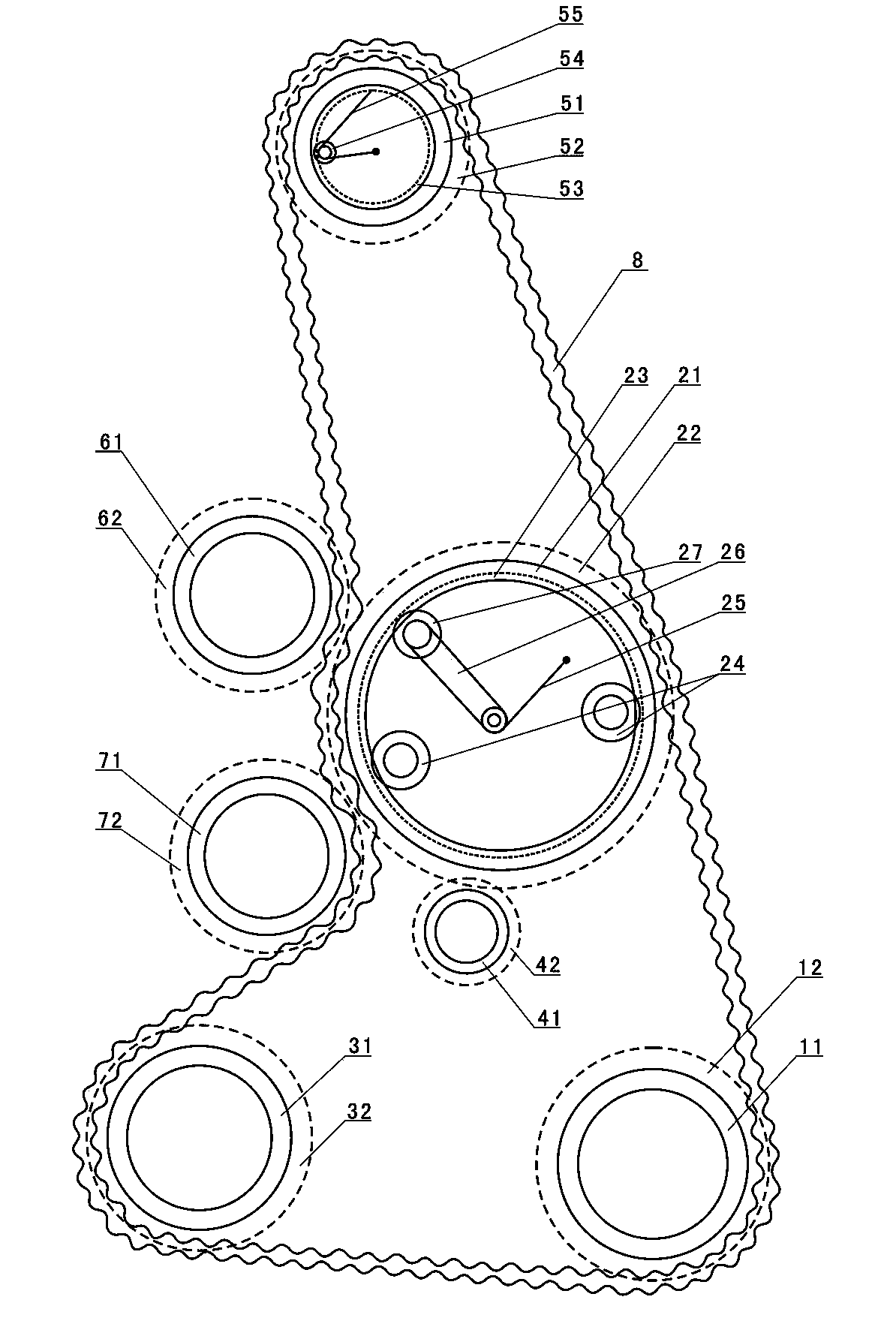

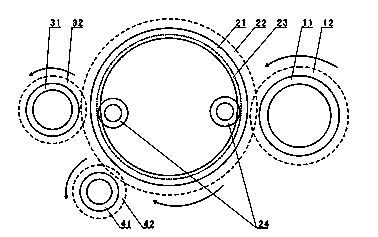

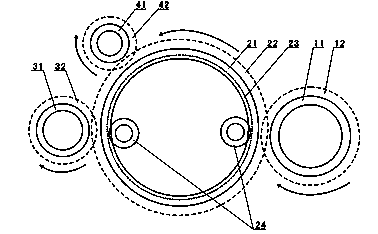

[0028] Such as figure 1 As shown, the power end gear 11, the load end gear 31 and the fulcrum gear 41 are directly meshed with the lever gear 21 respectively. An arc is formed, and the fulcrum gear 41 is located in the interval of the arc. In this example, the power end gear 11, the load end gear 31 and the fulcrum gear 41 all rotate counterclockwise, and the lever gear 21 rotates clockwise. The arc is located at figure 1 The lower peripheral area of the middle lever gear 21; the lever gear 21 is provided with external teeth 22 and a central through hole (not marked in the figure), the inner wall circumference of the lever gear 21 is provided with an annular groove 23, and the circumferential edge of the lever positioning wheel 24 is placed The positioning connection is realized in the annular groove 23 , and the power end gear 11 and the load end gear 31 are installed outside the lever gear 21 .

Embodiment 2

[0030] Such as figure 1 As shown, the power end gear 11, the load end gear 31 and the fulcrum gear 41 are directly meshed with the lever gear 21 respectively. An arc is formed, and the fulcrum gear 41 is located in the interval of the arc. In this example, the power end gear 11, the load end gear 31 and the fulcrum gear 41 all rotate clockwise, and the lever gear 21 rotates counterclockwise. The arc is located at figure 2 The upper peripheral area of the middle lever gear 21; the lever gear 21 is provided with external teeth 22 and a central through hole (not marked in the figure), the inner wall circumference of the lever gear 21 is provided with an annular groove 23, and the circumferential edge of the lever positioning wheel 24 is placed The positioning connection is realized in the annular groove 23 , and the power end gear 11 and the load end gear 31 are installed outside the lever gear 21 .

[0031] combine figure 1 with figure 2 , in the above-mentioned embodiment ...

Embodiment 3

[0036] Such as image 3 As shown, the power end gear 11, the lever gear 21, the transition gear 51 and the load end gear 31 are meshed and connected by a chain 8, and the power end gear 11, the transition gear 51 and the load end gear 31 are located outside the lever gear 21 respectively. The bead gears 61 and 72 are installed outside the lever gear 21 and close to the bead gear 21. The bead gears 61 and 72 make the chain 8 mesh with the power end gear 11, the lever gear 21, the transition gear 51, and the load end gear 31 respectively. transmission; the lever gear 21 is provided with external teeth 22 and a central through hole, and the inner wall circumference of the lever gear 21 is provided with an annular groove 23, and a mobile support arm 26 is also installed in the central through hole of the lever gear 21, and the first part of the mobile support arm 26 One end is installed in the position close to the central point in the lever gear 21, and the second end of the mobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com