An induction cooker without a cooling device

A technology for induction cookers and stoves, applied in the field of induction cookers, can solve problems such as burning or melting, unusable, melting of connecting wires, and achieve the effects of preventing burning or melting, solving safety accidents, and enhancing heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

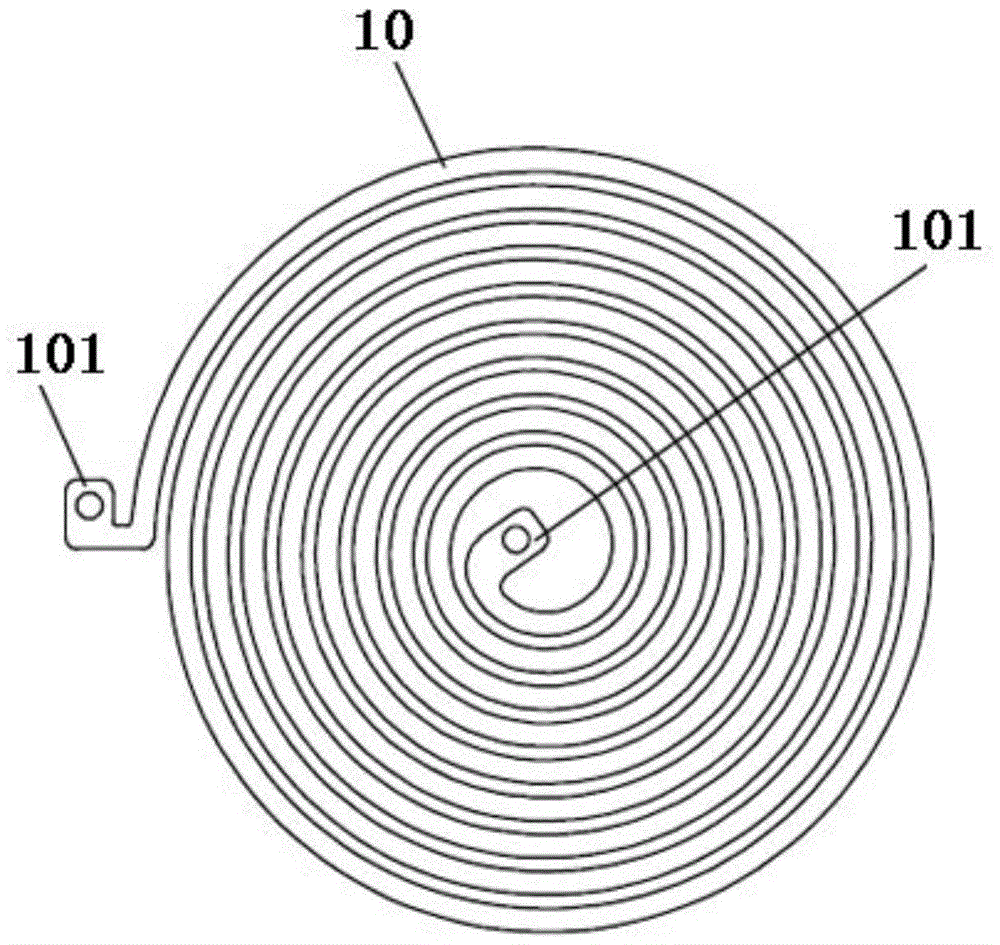

[0035] An electromagnetic cooker without a heat sink includes a connecting wire connected in sequence, a host mechanism and a cooker mechanism. The connecting wire is used to connect an external power supply to supply power to the host mechanism. In order to facilitate heat dissipation, the host mechanism and the stove mechanism in this embodiment are separated, that is, the host mechanism and the stove mechanism are separated, and the two are connected by wires; the host mechanism and the stove mechanism are separated, and the user can easily The stove mechanism is placed in a proper place away from the host mechanism, even if the water of the kitchen utensils placed on the stove mechanism overflows or falls, it will not affect the host mechanism, so that the host mechanism can be in a safer working environment.

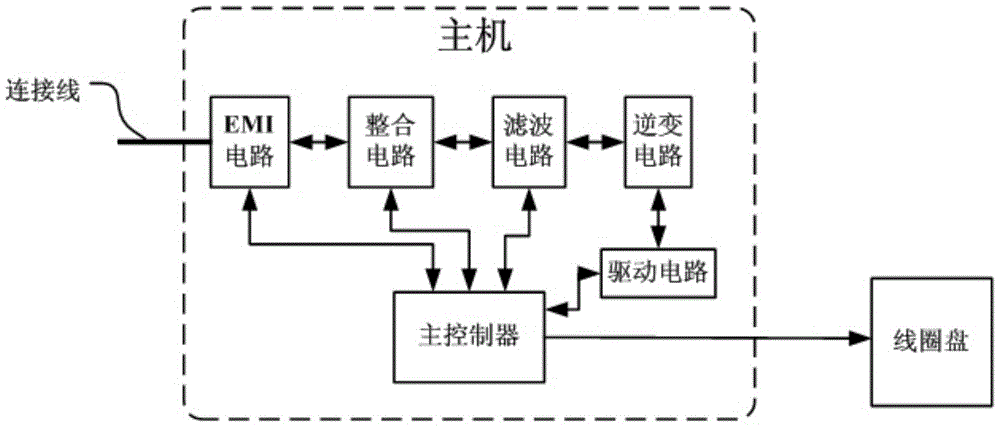

[0036] The host mechanism includes a main casing and a host, and the host is arranged in the main casing; the host includes a peripheral circuit and a main controlle...

Embodiment 2

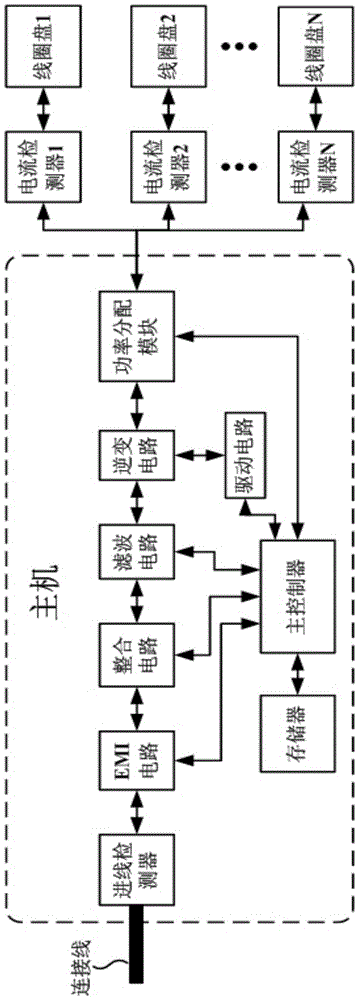

[0041] as attached image 3 As shown, compared with Embodiment 1, this embodiment is based on the original basis of Embodiment 1. A power distribution module and a memory are added to the host, and a device for detecting the temperature of the connecting wire is added between the connecting wire and the host mechanism. Incoming line detector; meanwhile, the stove mechanism in this implementation is different from the stove mechanism in Embodiment 1 in that the stove mechanism includes N single stove bodies, and each single stove body includes at least one stove body shell and one coil Disk, the coil disk is set in the stove body shell, N is an integer greater than or equal to 1 (in this embodiment, N is 3); the coil disk in each single stove body is output by a current detector and a power distribution module terminal connection, in this embodiment, the current detector is set in the cooker body shell. Since the stove mechanism is provided with a plurality of single stove bod...

Embodiment 3

[0056] as attached Figure 4 As shown, the induction cooker is provided with N host mechanisms and N stove mechanisms, and N is an integer greater than or equal to 1. It should be noted that the specific integer of N in this embodiment can be the same as N in Embodiment 2, or can be different;

[0057] Each stove mechanism also includes a current detector, the input end of the current detector is electrically connected to the main controller, and the output end of the current detector is electrically connected to the coil disk;

[0058]Each host mechanism also includes a memory connected to the main controller. The memory of each host mechanism stores power distribution priority relationship data that allocates the power priority relationship of each coil disk. The current detector is used to detect The current size of the disk, and feedback the detection result to the main controller, the main controller according to the current size fed back by the current detector, and acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com