Device and method for detecting ball stones in air bag type ball mill

A detection device and ball mill technology, applied in measuring devices, instruments, weighing and other directions, can solve the problems of difficulty in measurement, inability to detect the number of internal balls in real time, and no scientific detection, and achieve the effect of stable number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

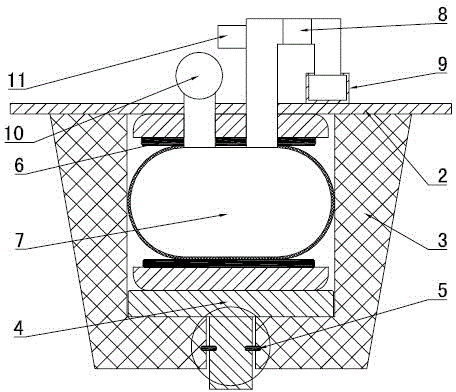

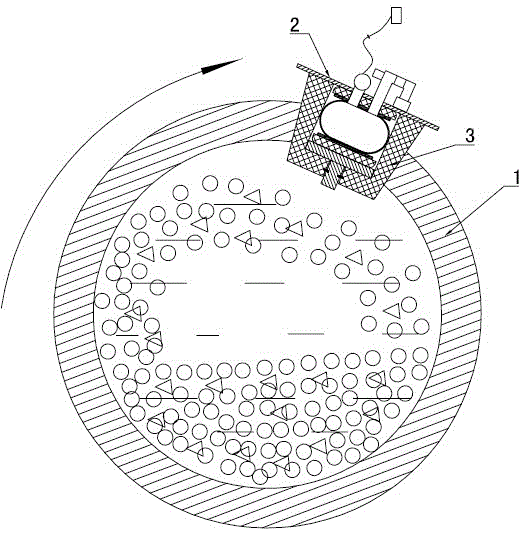

[0026] Figure 1~2 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~2 The present invention will be further described.

[0027] Refer to attached figure 1 , 2 : Ball stone detection device inside the airbag ball mill, including ball mill cover 2, protection head 3 and detection head 4, the lower part of ball mill cover 2 is provided with protection head 3 which can be plugged into the opening of ball mill 1, and protection head 3 is a tapered outer ring The columnar structure is so that it can be inserted into the opening of the ball mill 1 well. The protective head 3 is made of elastic rubber or plastic material, which can buffer the impact of ball stones and ore raw materials on the ball mill cover 2.

[0028] The inside of the protective head 3 is a cavity structure, and the bottom of the cavity is installed with the detection head 4 extending into the interior of the ball mill 1. The detection head 4 is an object with a T-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com