Backlight source detection device

A detection equipment and backlight technology, which is applied in the direction of optical instrument testing, optical testing defect/defect, optics, etc., can solve the problems of repeated inspection and missed inspection in the area, so as to improve inspection efficiency, reduce personnel loss, and improve defect detection rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The structure and principle of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

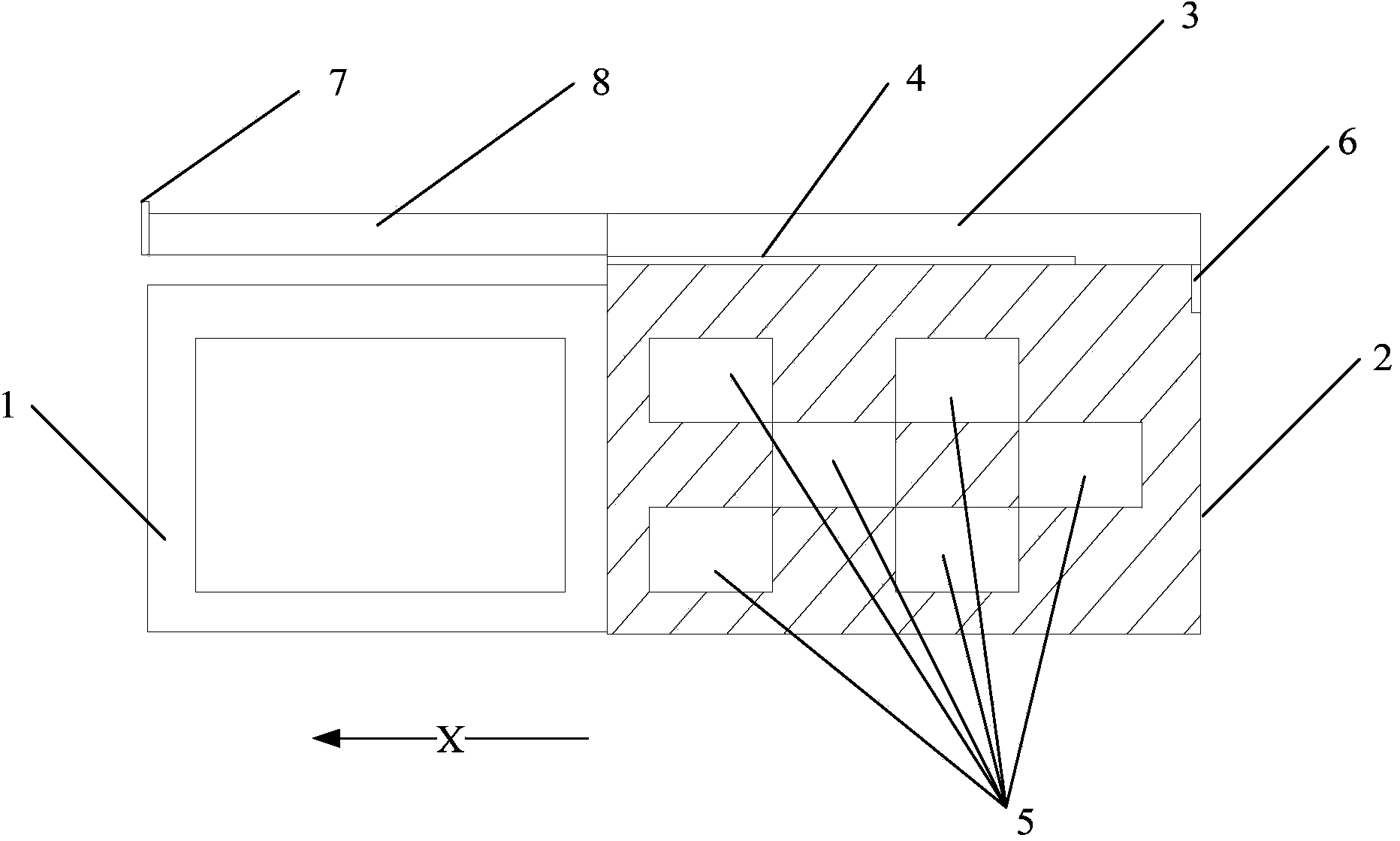

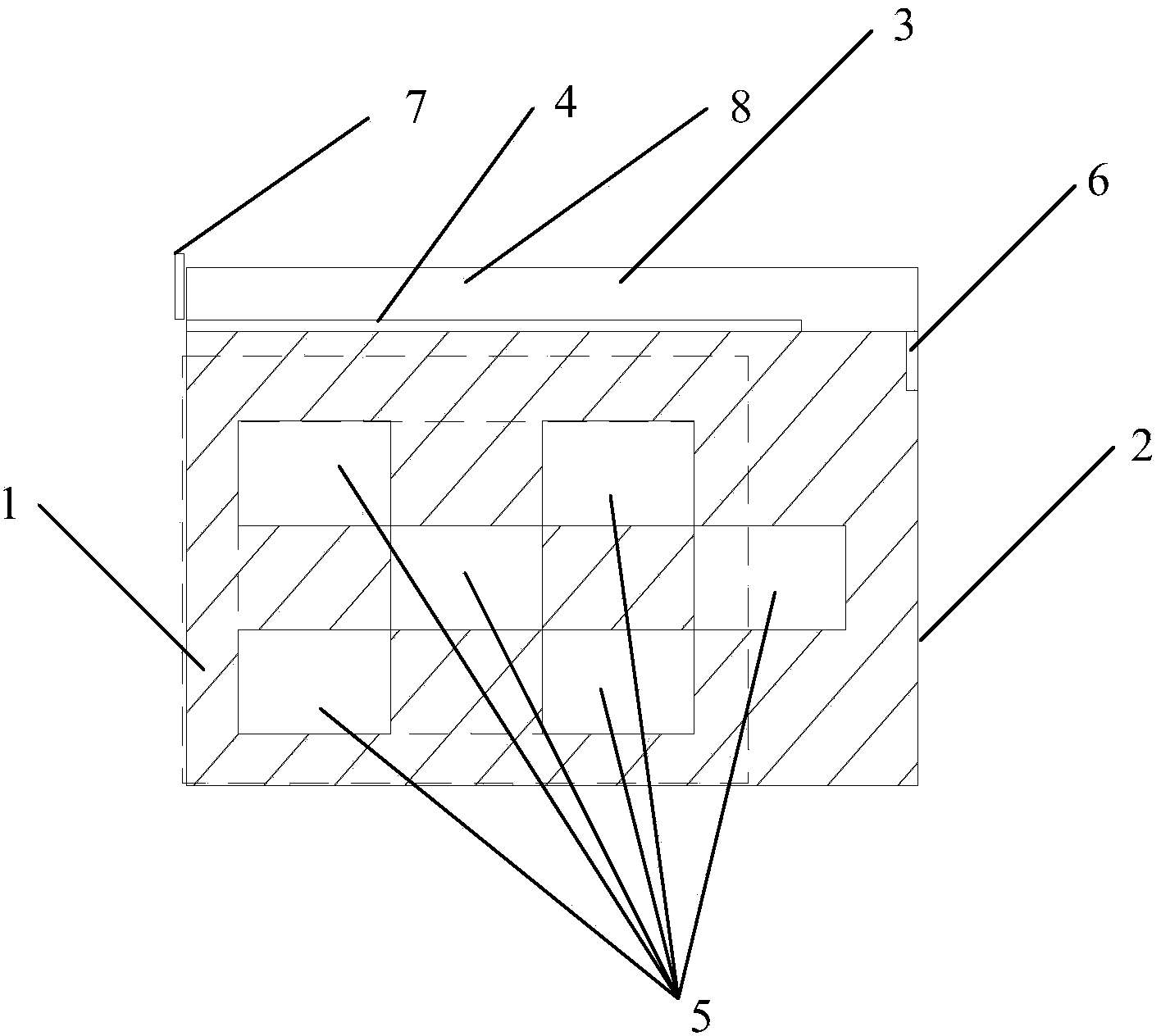

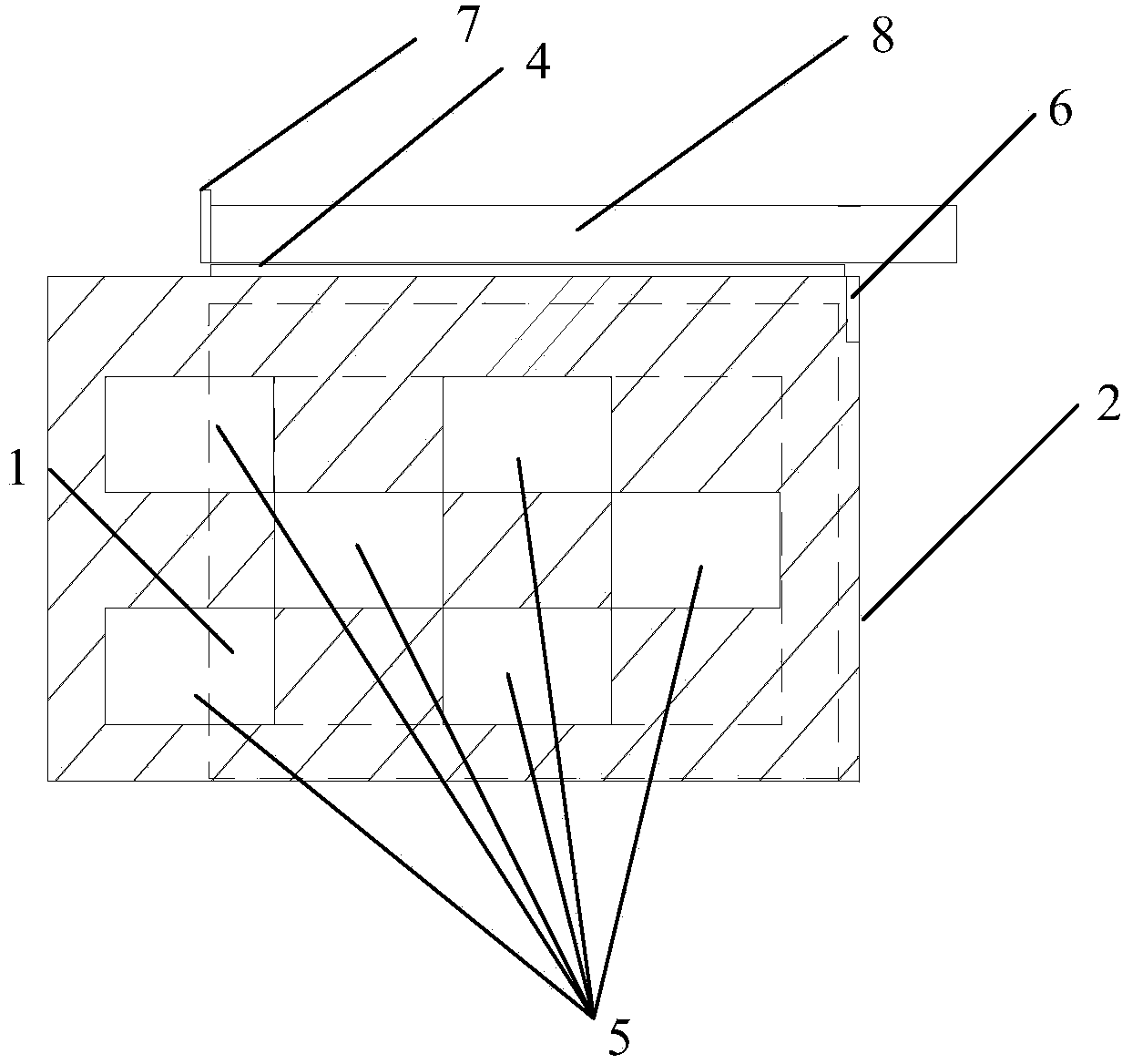

[0044] Such as Figure 1 to Figure 7 As shown, this embodiment provides a backlight detection device, which is characterized in that it includes:

[0045] The carrying platform 1 is used to place the backlight source to be detected; and

[0046] The inspection board 2 is arranged in a movable manner relative to the carrying platform 1, and can move from a first position to a second position;

[0047] When the inspection board 2 is in the first position, it exposes the first light-emitting area of the backlight to be tested, and blocks the second light-emitting area outside the first light-emitting area; when the inspection board 2 is in the second position, A third light-emitting area different from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com