Aging test method for simulating packer rubber sleeve under actual working conditions

A technology of aging test and actual working conditions, applied in the direction of material inspection products, etc., can solve problems such as few reports, and achieve the effect of ensuring simulation and reproducibility, and significantly accelerating aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention relates to an aging test method for simulating a packer rubber cylinder under actual working conditions, specifically comprising the following steps:

[0040] Step 1, select the hydrogenated nitrile rubber material, and process it into a cylindrical rubber sample, the size of the preferred sample of the present invention is Φ29 * 12.5mm;

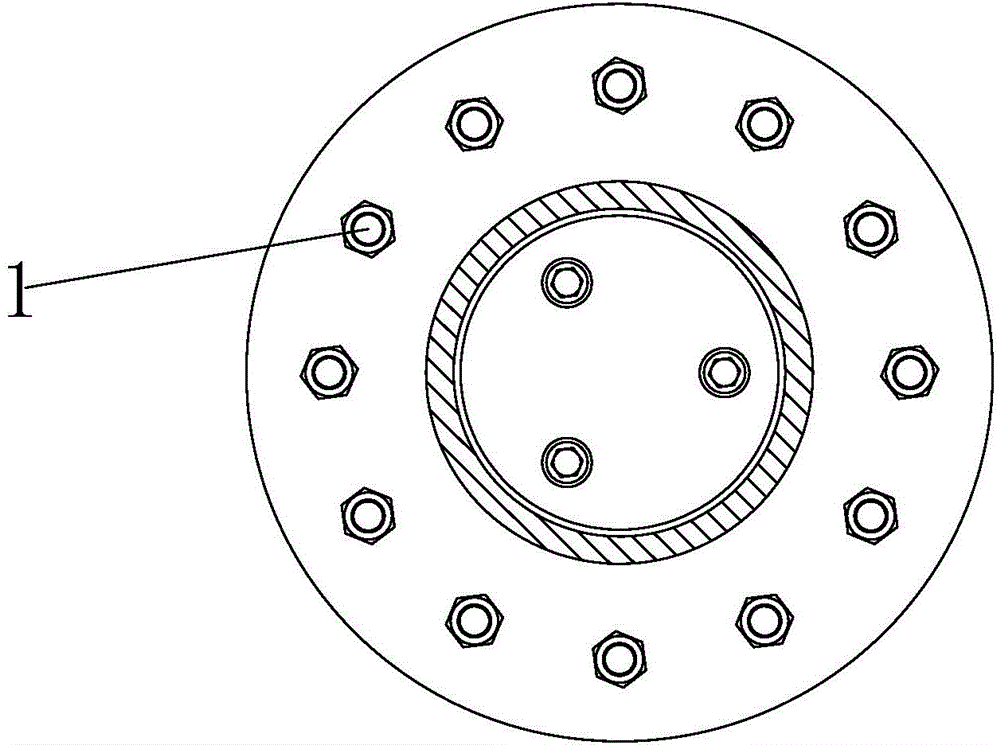

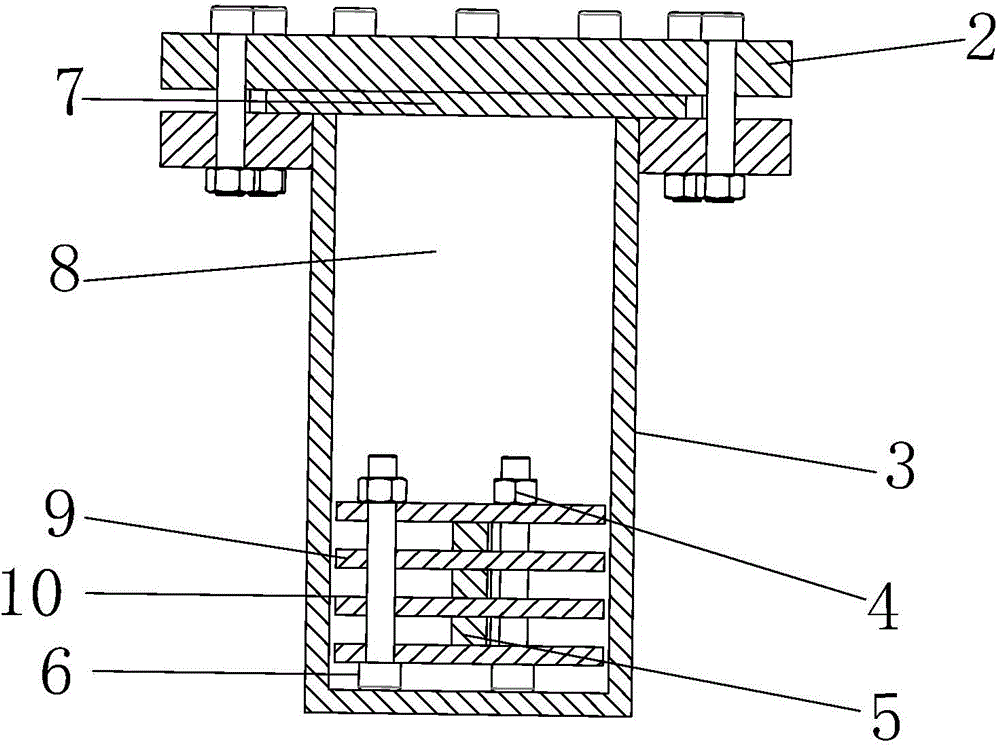

[0041] Step 2, prepare reaction device, the selected reaction device of the present invention comprises reactor and compression fixture, specifically combines figure 1 , figure 2 As shown, an aging test device for simulating the packer rubber cartridge under actual working conditions includes a reactor and a rubber compression fixture. The reactor includes a kettle body 3 and a cover for sealing the kettle body 3, and simulates During the test, the compression fixture is placed in the kettle body 3, and the simulation is performed by adding aging medium into the kettle body 3;

[0042] The compression fixture ...

Embodiment 2

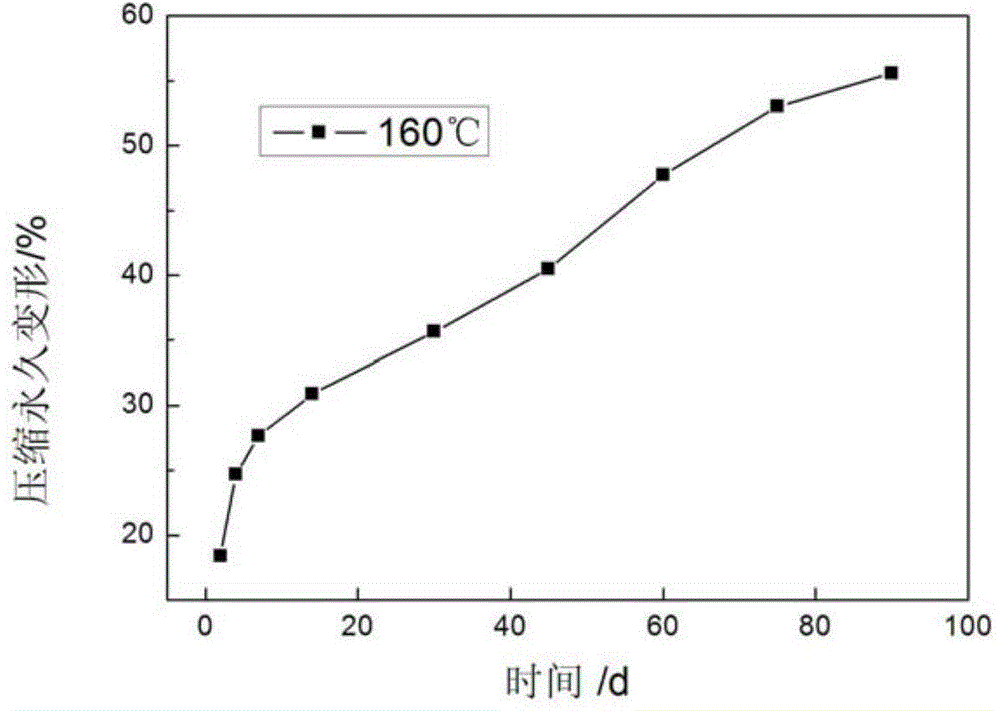

[0048] The difference from Example 1 is that in step 4, the aging temperature of the hydrogenated nitrile rubber is 180°C, and the compression set changes with the aging time as follows: Figure 4 shown. It can be seen from the figure that at this temperature, as the aging time prolongs, the ε value of the rubber increases; Figure 4 and image 3 It can be seen that the compression set of rubber increases with the increase of temperature.

Embodiment 3

[0050] The difference from Example 1 is that in step 4, the aging temperature of the hydrogenated nitrile rubber is 200°C, and the compression set varies with the aging time as follows: Figure 5 shown. It can be seen from the figure that at this temperature, as the aging time prolongs, the ε value of the rubber increases; Figure 5 and Figure 4 , image 3 It can be seen that the ε value of HNBR increases with the increase of temperature.

[0051] The invention simulates the aging of rubber samples under actual working conditions in the laboratory, and can study the aging performance and aging law of the rubber material of the packer rubber cylinder under the conditions of high temperature, stress and solution medium, and repeated tests prove that it has good reproducibility .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com