Method for simulating erosion acceleration test of high-strength aluminum alloys in industrial atmosphere environments

An accelerated test, aluminum alloy technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of little correlation, inaccurate results, difficult to evaluate the effect, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] An accelerated exfoliation corrosion test method simulating high-strength aluminum alloys in an industrial-marine atmospheric environment, comprising the following steps:

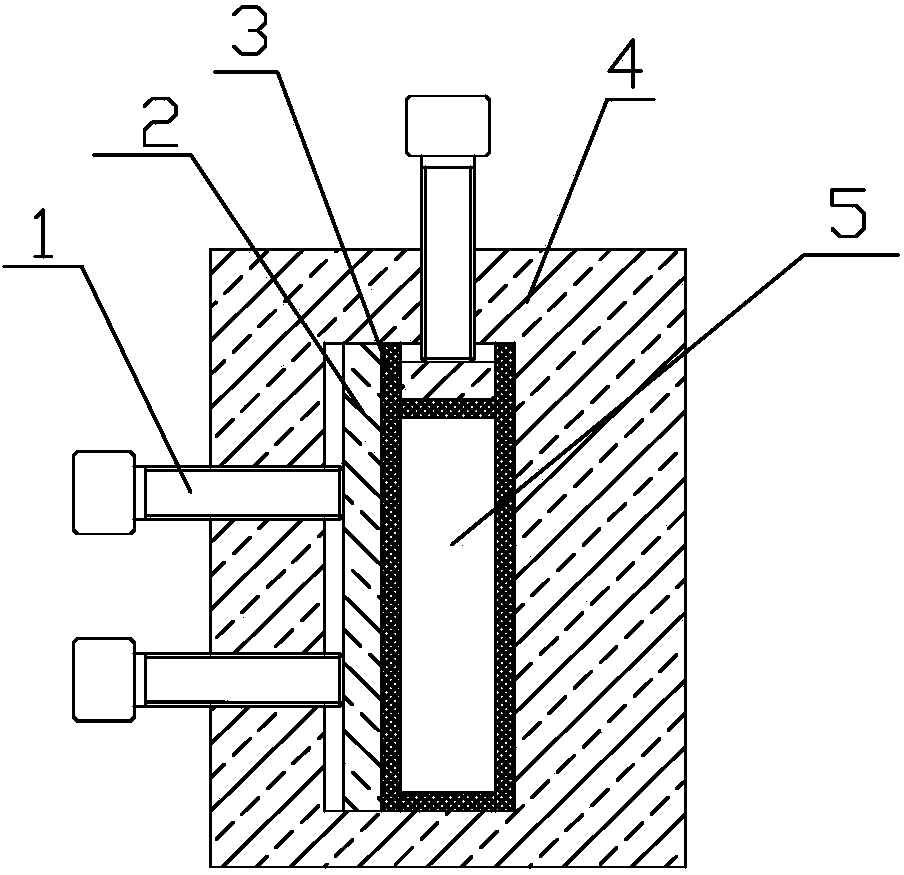

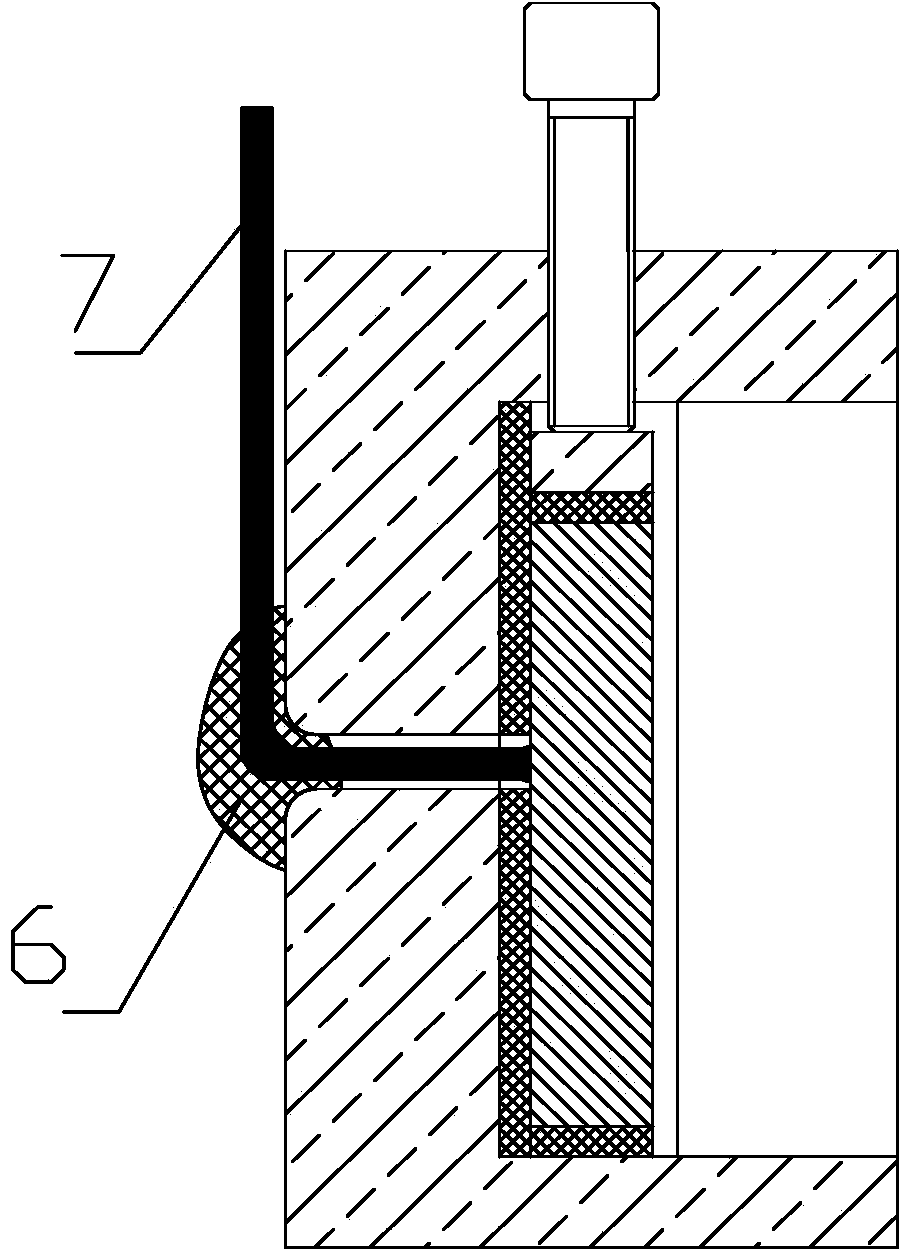

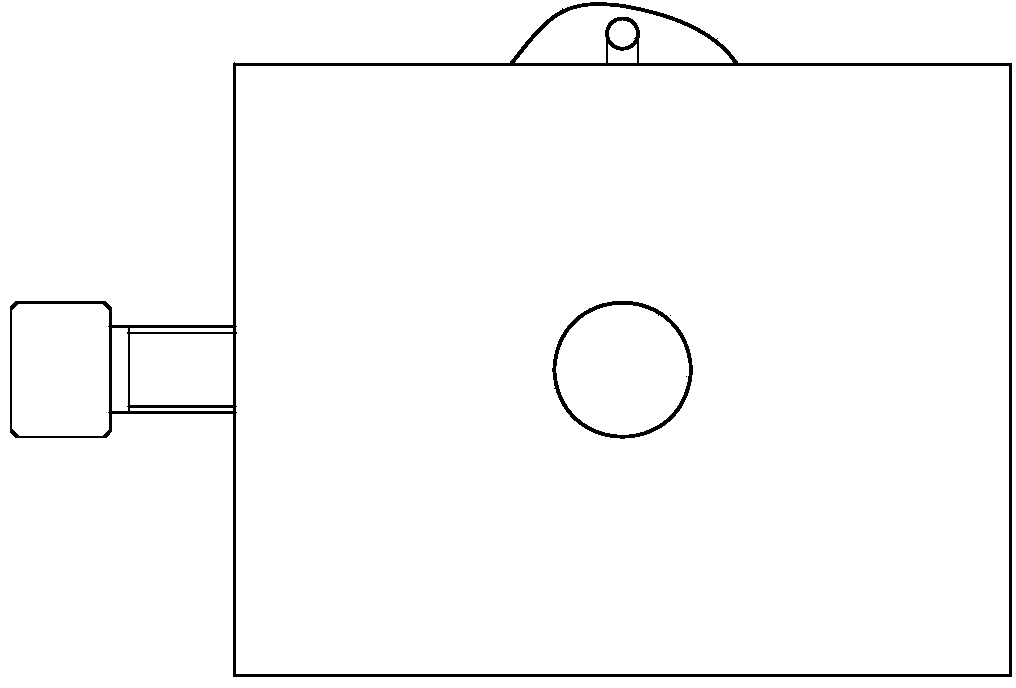

[0049] The first step is to prepare 1mol / L NaCl aqueous solution as the electrolyte solution, and pass the electrolyte solution into figure 2 In the plexiglass fixture shown, then immerse the above-mentioned pretreated sample in the electrolyte solution for constant potential pre-polarization. The constant potential is selected from -570 to -620mV, and polarized for 4 hours to obtain the polarized sample. ;

[0050] In the second step, put the polarized sample in the first step into distilled water for ultrasonic cleaning, and the cleaning time is 3 hours;

[0051] The 3rd step, set up constant environment with relative humidity and temperature by saturated salt solution humidity method and oven method, its temperature, relative humidity are as shown in Table 3,

[0052]

[0053] The fourth ste...

Embodiment 2

[0060] The first step is to prepare 1mol / L NaCl aqueous solution as the electrolyte solution, and pass the electrolyte solution into figure 1 In the plexiglass fixture shown, then immerse the above-mentioned pretreated sample in the electrolyte solution for constant potential pre-polarization. The constant potential is selected from -570 to -620mV, and polarized for 32 hours to obtain the polarized sample. ;

[0061] The second step is to put the polarized sample in the first step into distilled water for ultrasonic cleaning, and the cleaning time is 1 hour;

[0062] The 3rd step, set up constant environment with relative humidity and temperature by saturated salt solution humidity method and oven method, its temperature, relative humidity are as shown in Table 3,

[0063] table 3

[0064]

[0065] The fourth step, respectively prepare 0.6mol / L Na 2 SO 4 Solution and 0.6mol / L NaCl solution, mix the two as the impregnating solution;

[0066] The fifth step is to place ...

Embodiment 3

[0071] The difference from Example 1 is that in the fourth step, 0.15mol / L of Na 2 SO 4 solution and 0.6mol / L NaCl solution, mix the two as the impregnating solution.

[0072] Figure 5 It is the exfoliation corrosion diagram of the side of the sample exposed for 26 days, 33 days, 39 days, 48 days, 55 days, and 61 days in this example. As the exposure time prolongs, the corrosion of the 2024 high-strength aluminum alloy sample becomes more and more serious ; Figure 5 The left side of the middle sample is the constant potential polarization surface. After the accelerated exfoliation corrosion test, the exfoliation corrosion occurred along the left side of the sample from left to right. After 26 days of the test, the elongated grains inside the 2024 high-strength aluminum alloy were caused by corrosion products Al(OH) 3 and Al 2 SO 4 (OH) 4 ·H 2 O was pried up due to the wedge-shaped force. As the test time prolongs, more and more corrosion products are produced, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com