Control system for curing forming of bent portion of stator coil of large-capacity air-cooled generator

A control system and stator coil technology, applied in the control/adjustment system, non-electric variable control, temperature control, etc., can solve the problems of low quality standard rate of stator coil, unstable temperature control, manual process adjustment, etc., and achieve quality The effect of improving, liberating labor force and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

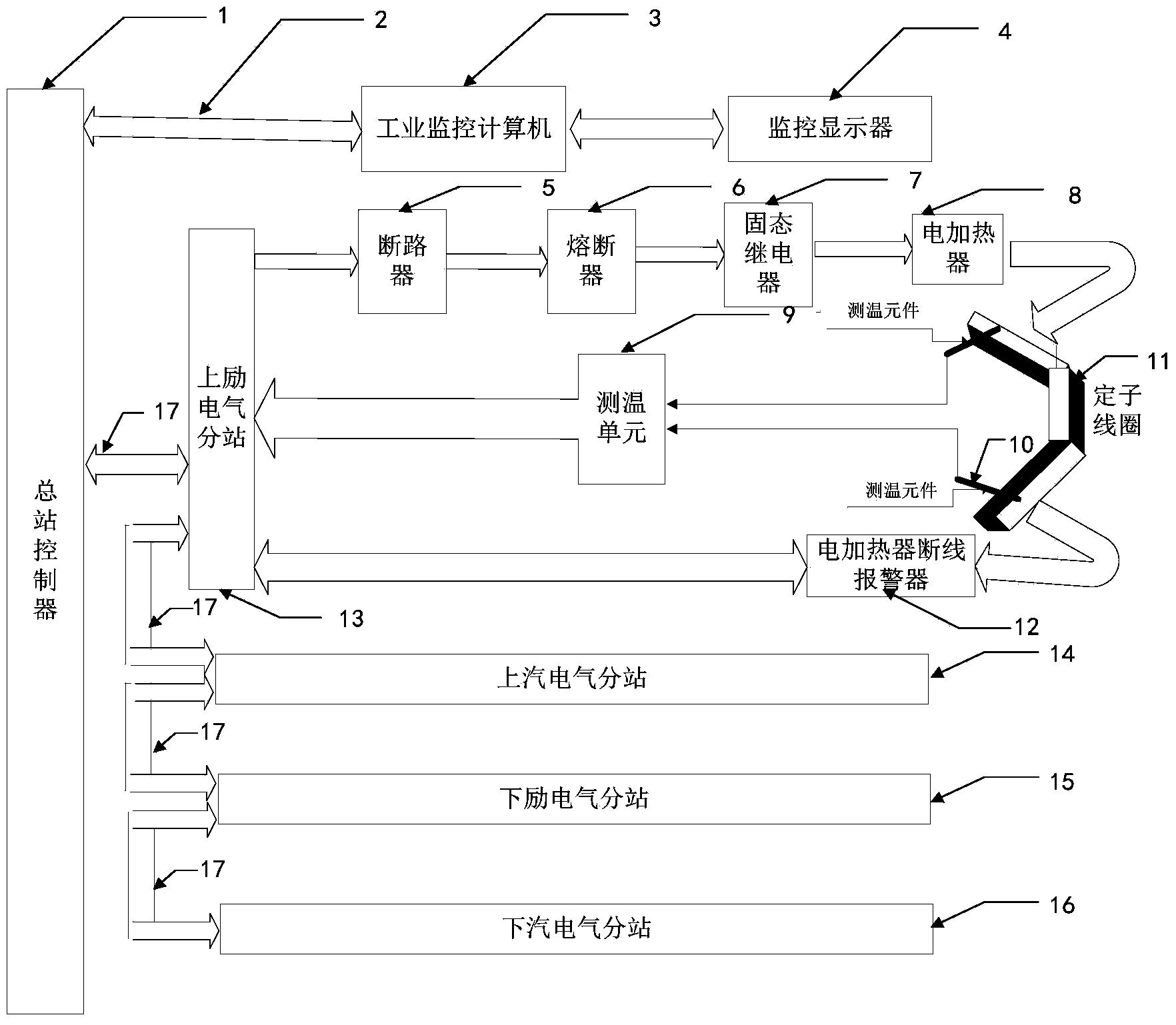

[0032] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, a large-capacity air-cooled generator stator coil 11 bending part solidification and molding control system includes a total station control system, a heating and curing temperature control drive system, a temperature control system, a heater disconnection detection system, an industrial monitoring system, and a mechanical and electrical distribution system. stand;

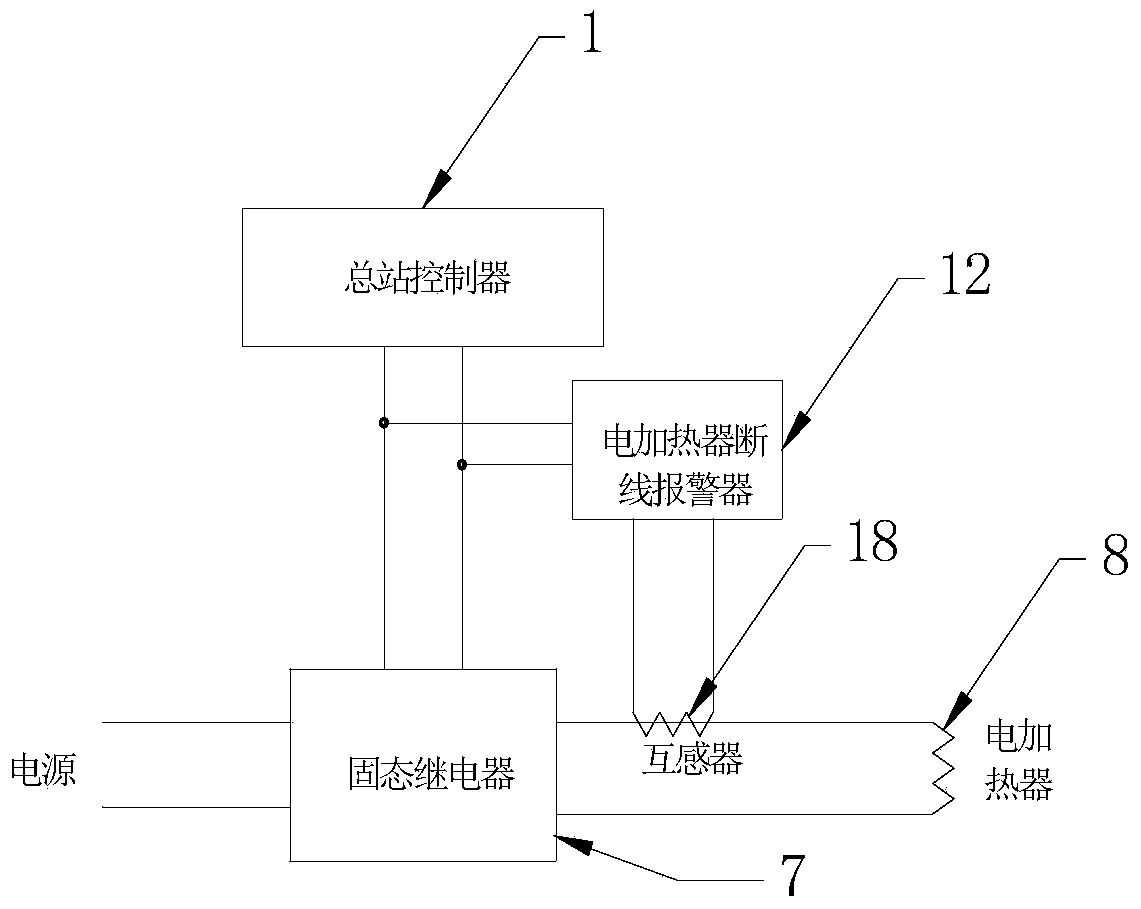

[0033] Described total station control system includes total station controller 1, MPI communication cable 2 and Profibus-DP bus communication cable 17; Described heating and curing temperature control drive system includes circuit breaker 5, fuse 6, solid state relay 7 and electric Heater 8, described temperature control system is made up of temperature measuring unit 9 and temperature measuring element 10, and temperature measuring element 10 adopts high-precision PT temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com