Mixed wafer level vacuum packaging method and structure based on banding getter

A technology of vacuum encapsulation and getter, which is applied in the directions of microstructure devices without moving elements, microstructure technology, microstructure devices, etc., which can solve the problems of low efficiency, waste of infrared filters, poor performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] This embodiment provides a hybrid wafer-level vacuum packaging method based on a strip-shaped getter, including the following steps:

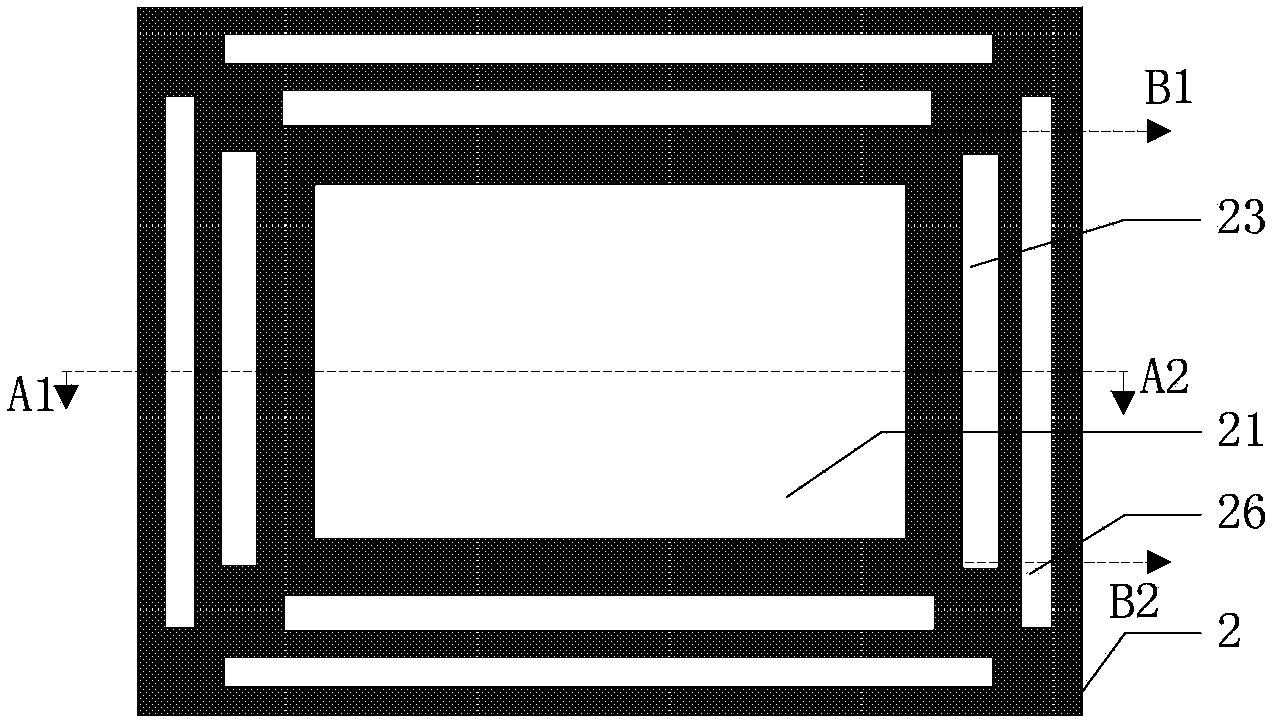

[0090] First carry out step a), provide a gasket 2, a substrate sheet 1 and a cover sheet, form a chip package cavity 21 and at least one getter cavity 23 in the gasket 2, and form a chip package cavity 21 in the chip package cavity 21 Vent holes 27 are formed in the spacer 2 between the getter chamber 23 and the getter chamber 23 .

[0091] Then proceed to step b), bonding the gasket 2 and the substrate 1 to form a package cavity.

[0092] Then proceed to step c), making composite metal layers 12, 22 on the upper surface of the substrate 1 and the gasket 2, or making a composite metal layer 22 on the upper surface of the gasket 2 and making a composite metal layer on the lower surface of the cover sheet.

[0093] Then proceed to step d), providing a chip to be packaged, bonding the chip to be packaged that has passed the test to the su...

Embodiment 2

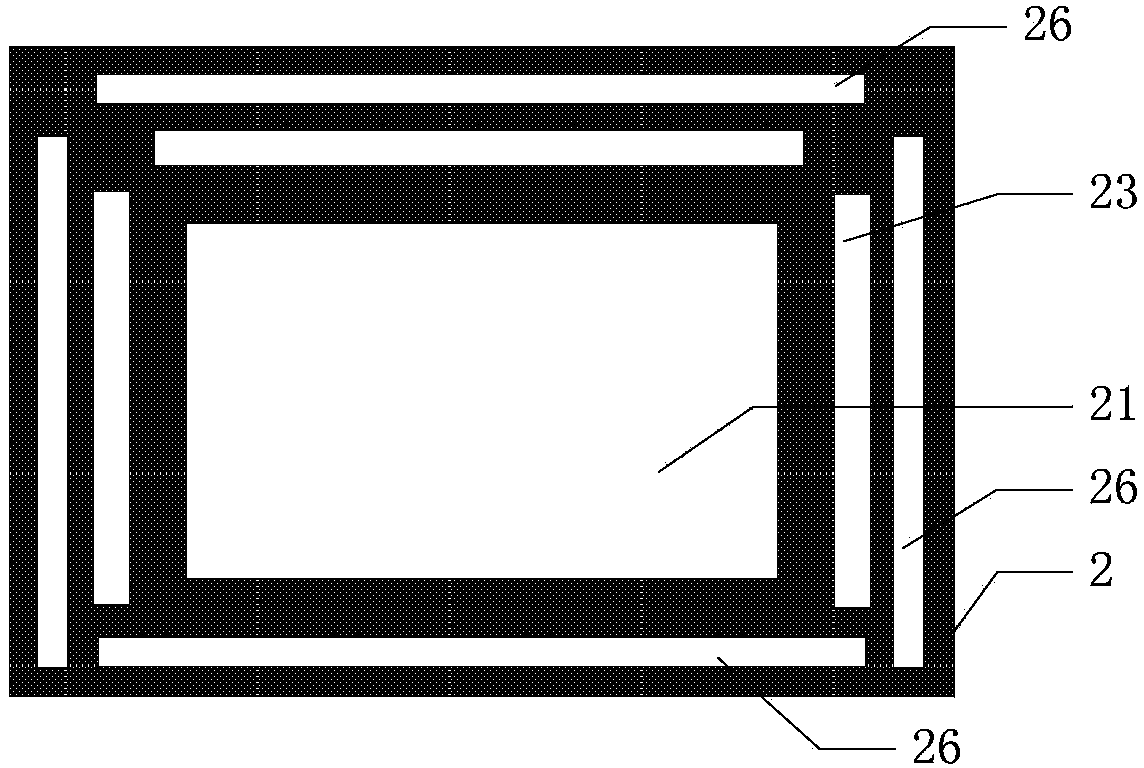

[0132] Such as Figure 5 As shown, this embodiment provides a hybrid wafer-level vacuum packaging method based on a tape-shaped getter, and its basic steps are as in Embodiment 1, wherein the cover sheet is fixed on a surface that matches the size of the substrate sheet Separators in the jig.

[0133] Such as Figure 5 As shown, this embodiment also provides a hybrid wafer-level vacuum packaging structure based on a strip-shaped getter, the basic structure of which is as in Embodiment 1, wherein the cover sheet is fixed on a Separators in matching jigs.

Embodiment 3

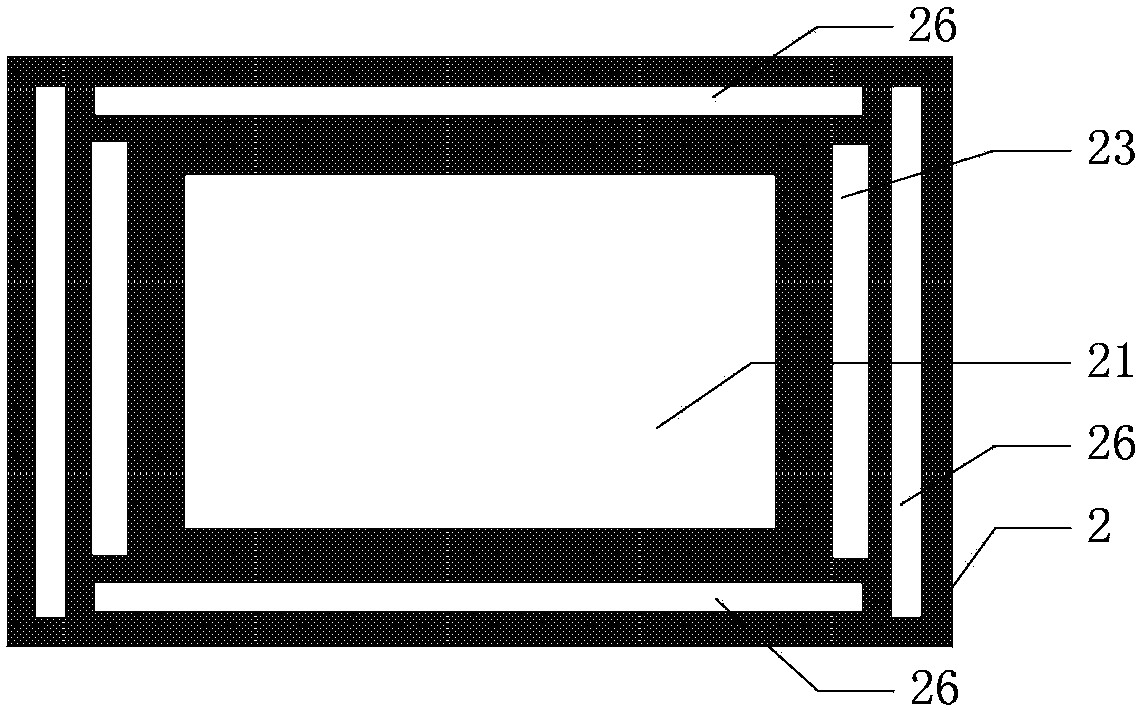

[0135] Such as Figure 6 As shown, this embodiment provides a hybrid wafer-level vacuum packaging method based on a strip-shaped getter, and its basic steps are as in Embodiment 1, wherein, this embodiment does not need to form through holes in the substrate sheet and the chip to be packaged structure and metal posts, but form a through-hole structure for the leads of the chip to be packaged in the cover sheet, and form a metal post 33 in the through-hole structure of the cover sheet; the thermal infrared detector is not a bond bonded to the surface of the substrate but to the surface of the cover slip.

[0136] Such as Figure 6 As shown, this embodiment also provides a hybrid wafer-level vacuum packaging structure based on a strip-shaped getter. Hole structure and metal column, and the through-hole structure and metal column 33 used for the lead of the chip to be packaged are formed in the cover sheet; the thermal infrared detector is not bonded to the surface of the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com