Greenhouse aeroponic culture vegetable harvesting machine

A harvester and vegetable technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of manual operation and low overall level, and achieve the effect of saving costs, improving work efficiency and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

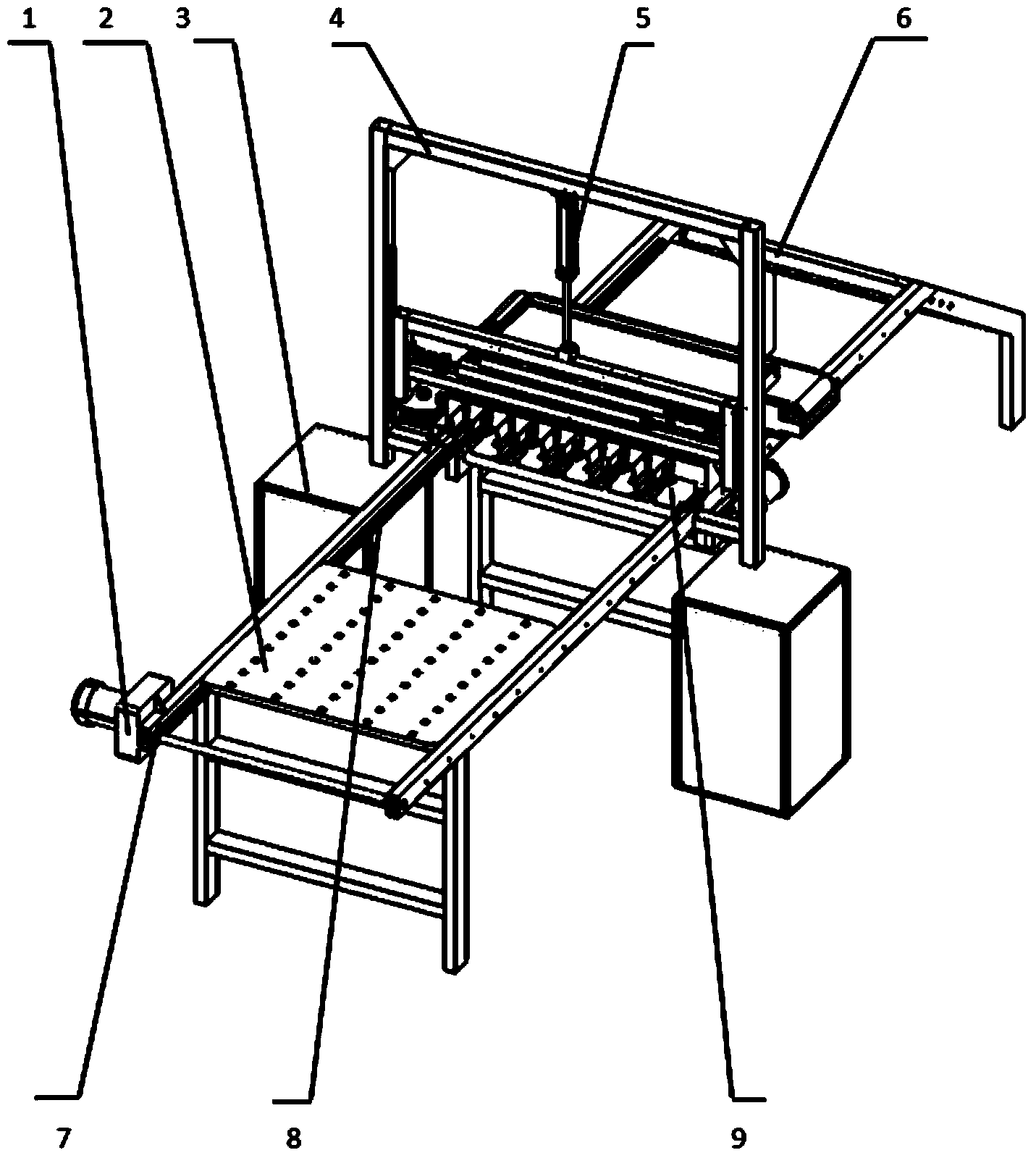

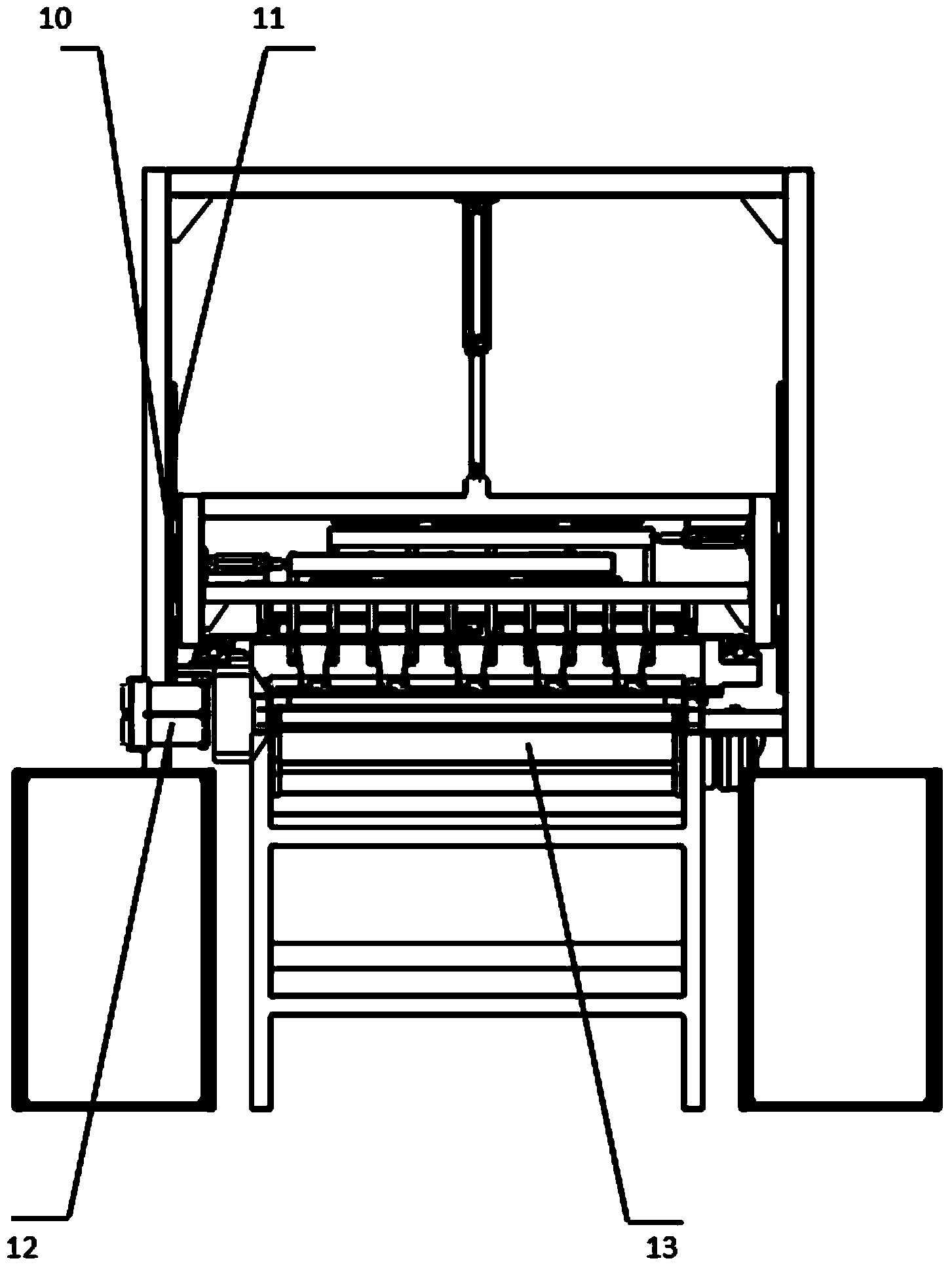

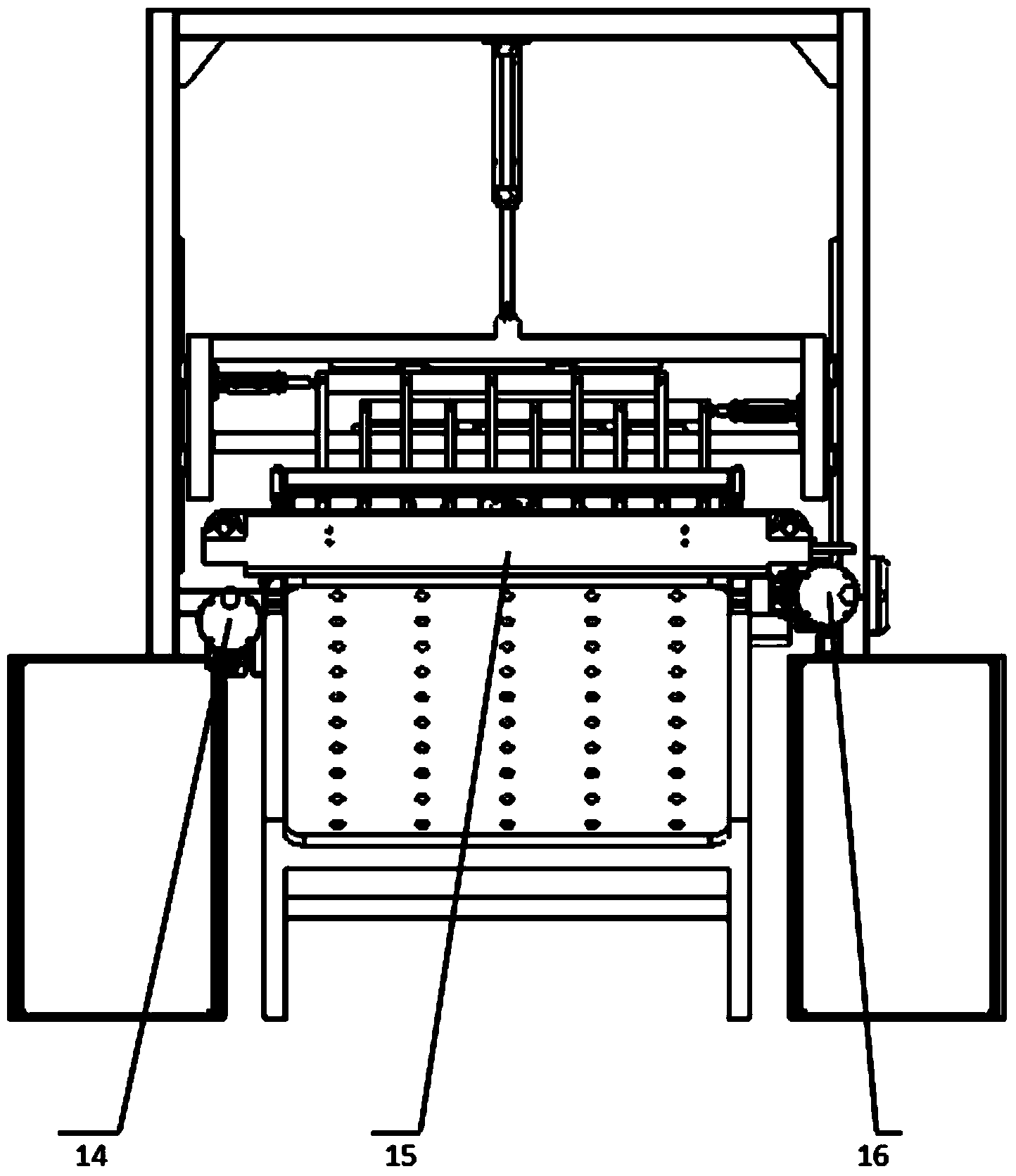

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] Such as figure 1 , figure 2 , image 3 As shown, the patent of the present invention is a planting plate greenhouse aeroponic vegetable harvester, including a planting plate transport mechanism, a vegetable clamping mechanism, a root cutting mechanism and a vegetable transport mechanism. The planting board transportation mechanism includes: mainly composed of a transportation frame 1; a motor I12, which drives the transportation frame roller 8 to drive the transportation frame conveyor belt 7 to run. The planting plate 2 moves forward on the transport frame conveyor belt 7 to under the harvesting platen 9, wherein the planting groove in the planting plate 2 is aligned with the notch of the harvesting platen 9, so that the mature vegetable stem is stuck in the harvesting platen 9 notches.

[0028] The vegetable clamping mechanism is installed above the transport f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com