Timed quantitative feeder

A timing quantitative, food utensil technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of feeding amount error, computer, logic analyzer complexity, high cost, etc., to achieve low power consumption, accurate food quantitative, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

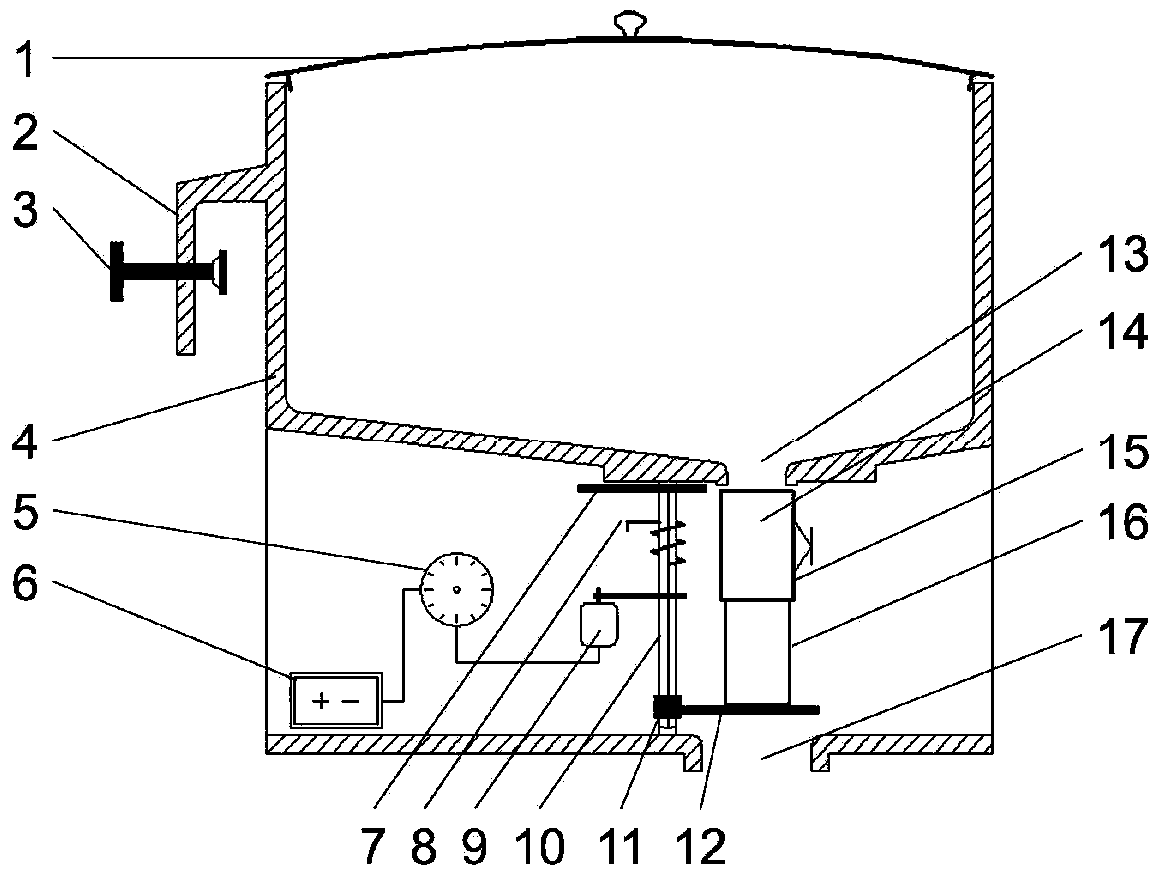

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

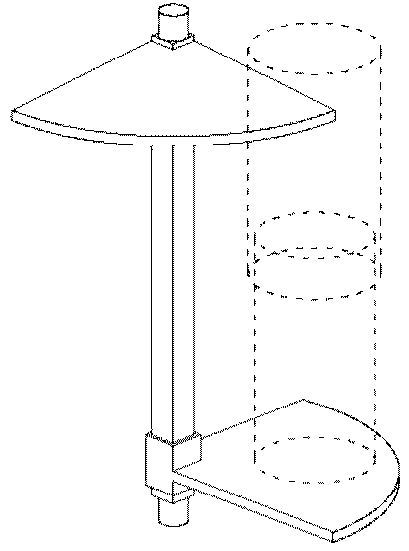

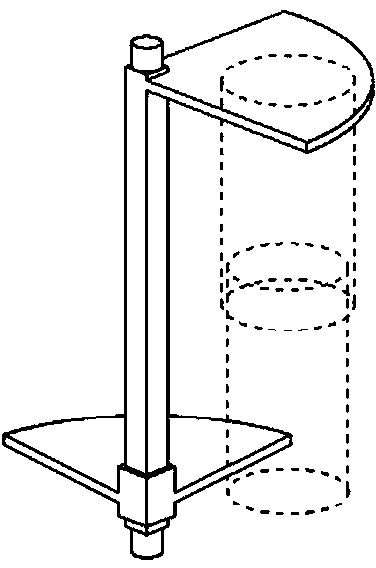

[0023] as attached figure 1 Shown is a schematic structural view of a timing and quantitative feeder in the present invention. The shell on the top of the food feeder constitutes the material storage box (4), and is provided with a matching lid (1), and the hole (13) for discharging food is arranged at the bottom of the material storage box (4), and the hole (13) is set to bottom lowest position. A quantitative cylinder (14) is provided directly below the hole (13), which includes a fixed cylinder (15) and a telescopic cylinder (16) enclosed within the fixed cylinder. The fixed cylinder (15) is fixed to the feeder shell and cannot be moved; The telescopic tube (16) can be pushed up and down along the fixed tube. like Figure 4 As shown, the zigzag structure between the fixed cylinder (15) and the telescopic cylinder (16) ensures that the position between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com