Permanent magnet sintering material box and material stacking method

A permanent magnet, material box technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

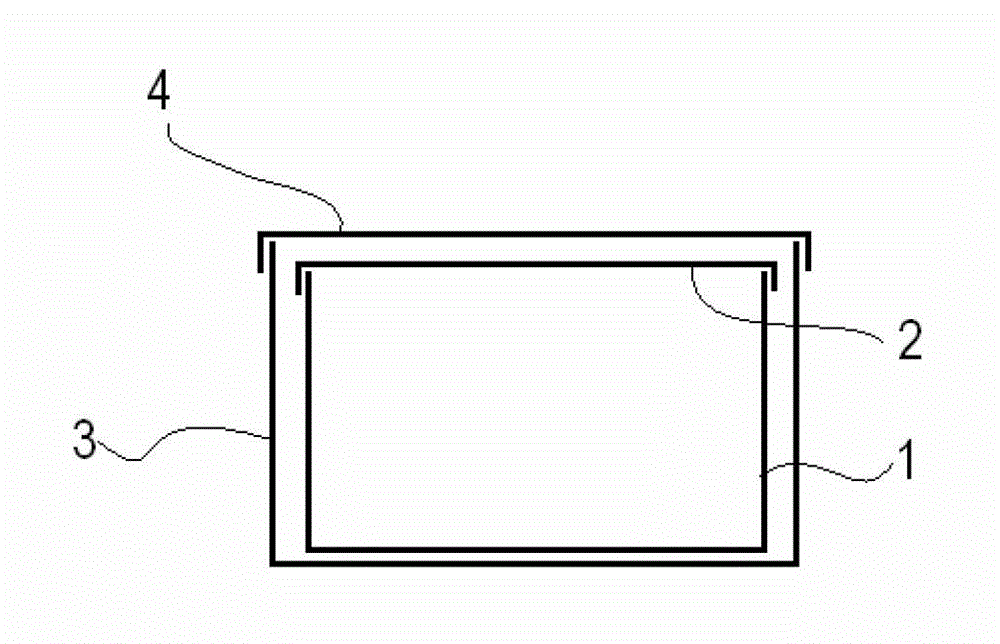

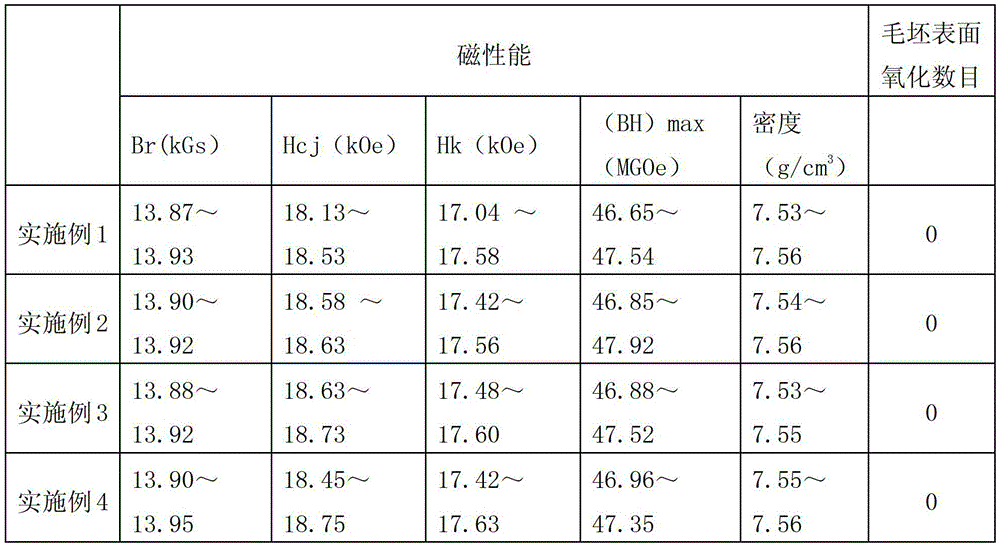

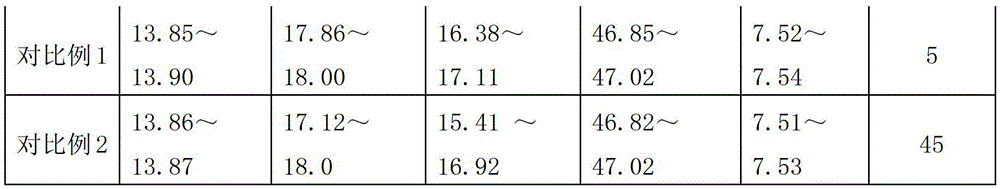

[0031] Embodiment 1: A tinplate sheet with a thickness of 0.15mm is selected to make a material box for inner layer sintering, including a box body 1 and a box cover 2, and the gap between the box body 1 and the box cover 2 is 0.08mm. The box body 3 and the box cover 4 of the outer sintered material box are made of Q235 steel. Put the box body 1 of the inner layer sintering material box into the box body 3 of the outer layer sintering material box and put it into the box body filled with protective gas N 2 In the glove box, put the pressed compact into the protective gas N 2 In the glove box, the oxygen content should not exceed 0.05ppm, and the compact size is 56*49*40mm. Put the compact into the box body 1 of the material box for inner layer sintering, fasten the box cover 2 first after the stack is full, and then fasten the box cover 4. Load the double-layer magazine full of blanks into a protective gas N 2 Store in containers. It takes 5 hours (hours) from the beginnin...

Embodiment 2

[0032] Embodiment 2: A tinplate sheet with a thickness of 0.23 mm is selected to make a material box for inner layer sintering, including a box body 1 and a box cover 2, and the gap between the box body 1 and the box cover 2 is 0.05 mm. The box body 3 and the box cover 4 of the outer sintered material box are made of Q345 steel. Put the box body 1 of the inner layer sintering material box into the box body 3 of the outer layer sintering material box and put it into the box body filled with protective gas N 2 In the glove box, put the pressed compact into the protective gas N 2 In the glove box, the oxygen content should not exceed 0.05ppm, and the compact size is 56*49*40mm. Put the compact into the box body 1 of the material box for inner layer sintering, fasten the box cover 2 first after the stack is full, and then fasten the box cover 4. Load the double-layer magazine full of blanks into a protective gas N 2 Store in containers. It takes 5 hours from the beginning of p...

Embodiment 3

[0033] Embodiment 3: A tinplate sheet with a thickness of 0.28 mm is selected to make a material box for inner layer sintering, including a box body 1 and a box cover 2, and the gap between the box body 1 and the box cover 2 is 0.1 mm. The box body 3 and the box cover 4 of the outer sintered material box are made of Q235 steel. Put the box body 1 of the inner layer sintering material box into the box body 3 of the outer layer sintering material box and put it into the box body filled with protective gas N 2 In the glove box, put the pressed compact into the protective gas N 2 In the glove box, the oxygen content should not exceed 0.05ppm, and the compact size is 56*49*40mm. Put the compact into the box body 1 of the material box for inner layer sintering, fasten the box cover 2 first after the stack is full, and then fasten the box cover 4. Load the double-layer magazine full of blanks into a protective gas N 2 Store in containers. It takes 5 hours from the beginning of pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com