Automatic transistor element tapping machine

A tapping machine and triode technology, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve the problems of low automation and slow processing speed of triode manual tapping, and achieve a high degree of automation and solve the degree of automation. The effect of low, broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

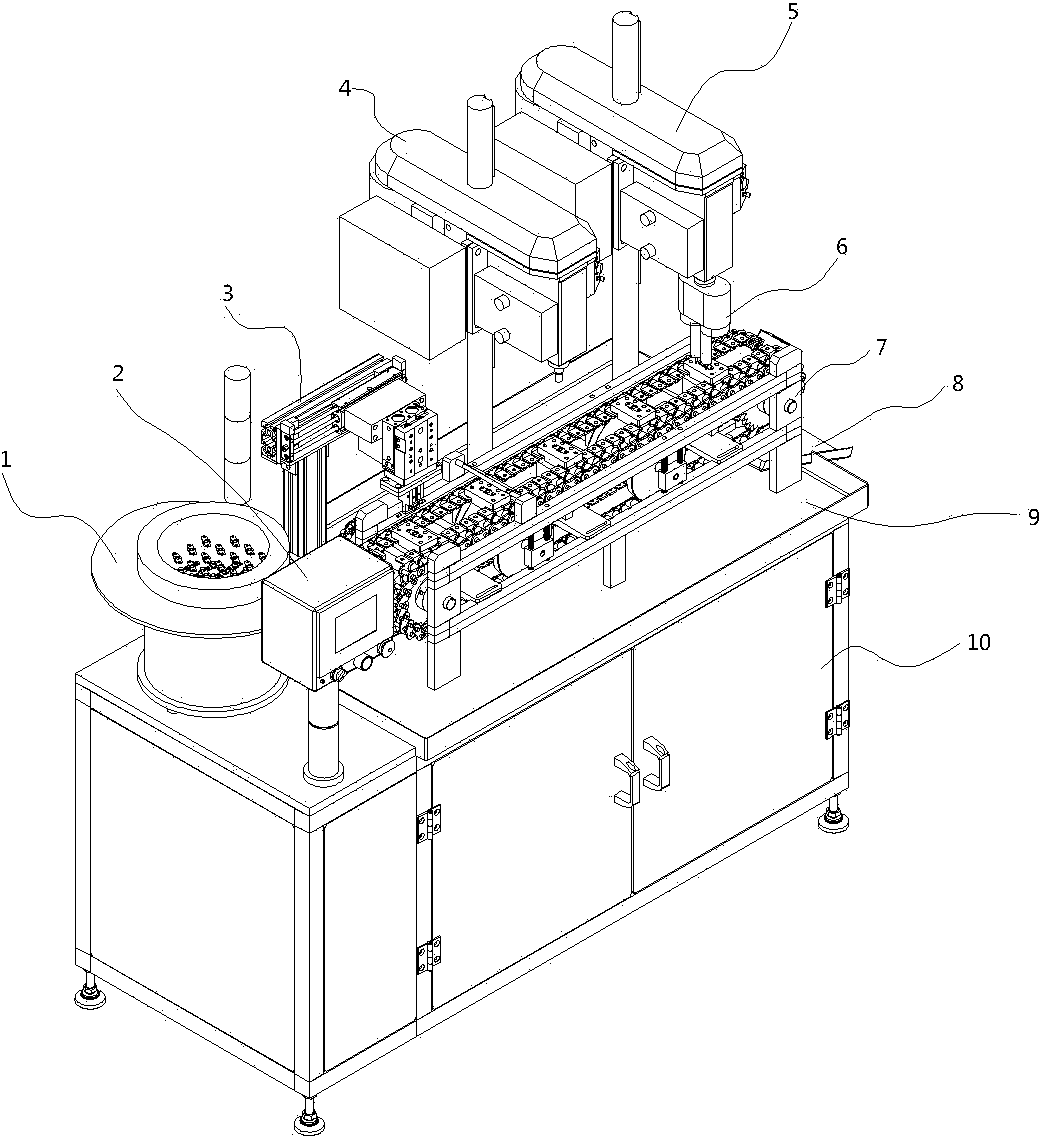

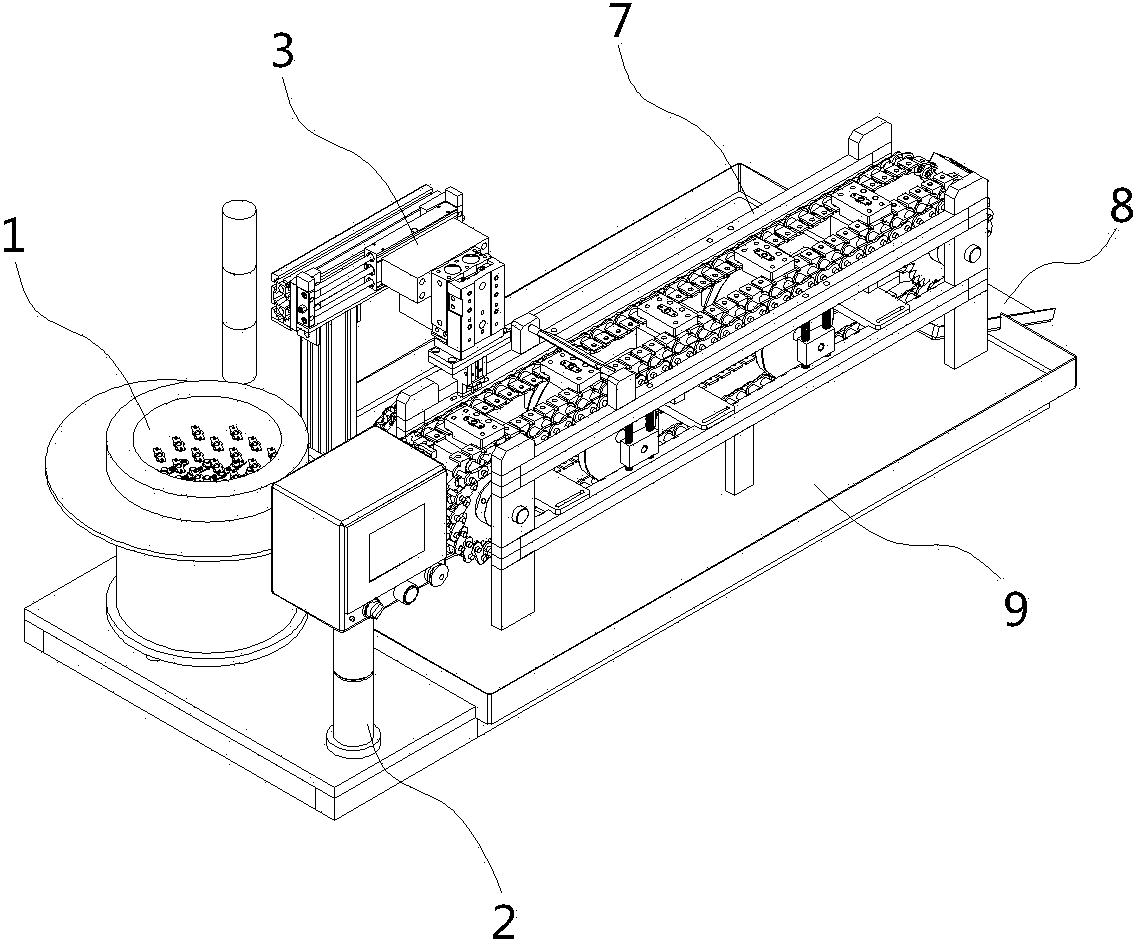

[0025] Please focus on figure 1 and figure 2 , an automatic tapping machine for triode components, including a frame 10, a workbench 9 is installed on the frame 10, a material transfer device 7 is installed on the workbench 9, a reaming drilling machine 4 and a drilling drilling machine 5 are installed The side of the feeding device 7 is used to process the workpiece on the feeding device 7, wherein: a double tapping drill bit 6 is installed under the drilling machine 5; the feeding device 3 is installed at the end of the feeding device 7, and its side The vibrating plate 1 is installed, the material frame 12 is connected to the discharge port of the vibrating plate 1, and the discharging plate 8 is installed at the discharging end of the feeding device 7; the control box 2 is installed on the workbench 9 to control the whole machine.

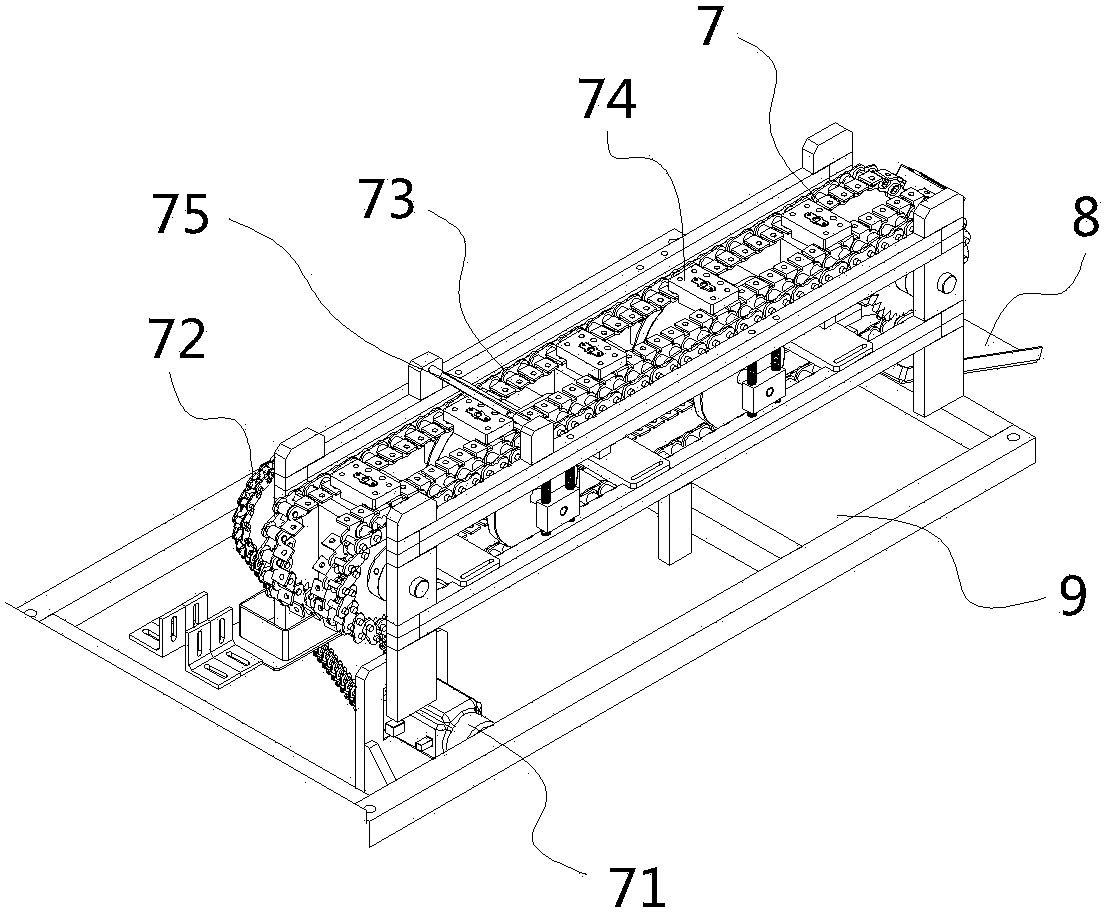

[0026] Please focus on image 3 , the feeding device 7 includes a drive chain 73, a workpiece groove 74 installed in the middle of the d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap