Insert positioning structure in die

A technology of insert positioning and mold, which is applied in the direction of coating, etc., can solve problems such as easy scratches and material leakage, affect product quality and performance, and product scrapping, so as to prevent material leakage, improve quality and pass rate, prevent strong sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

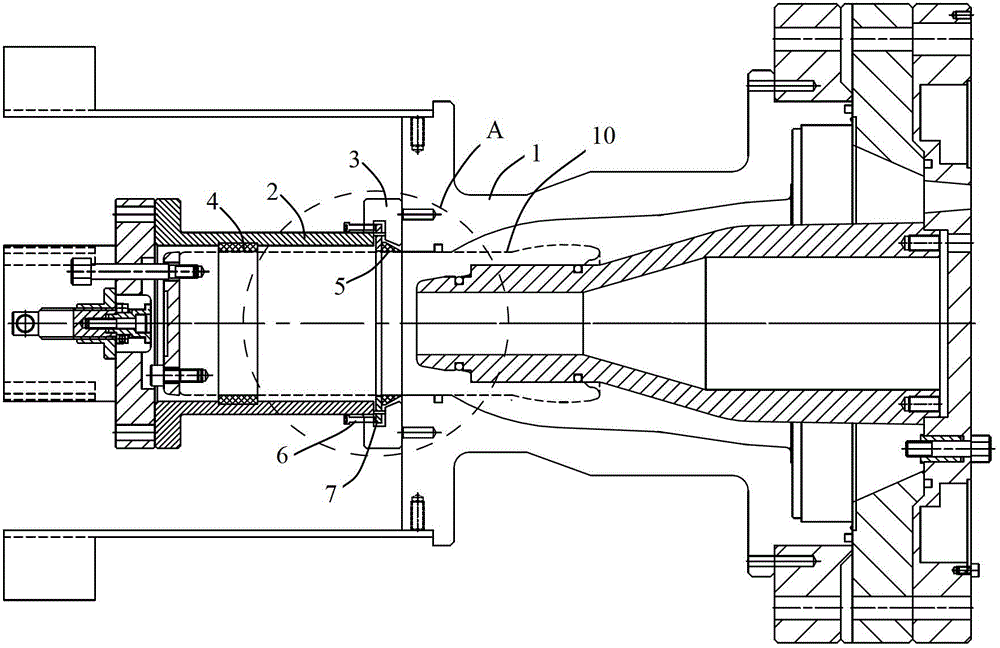

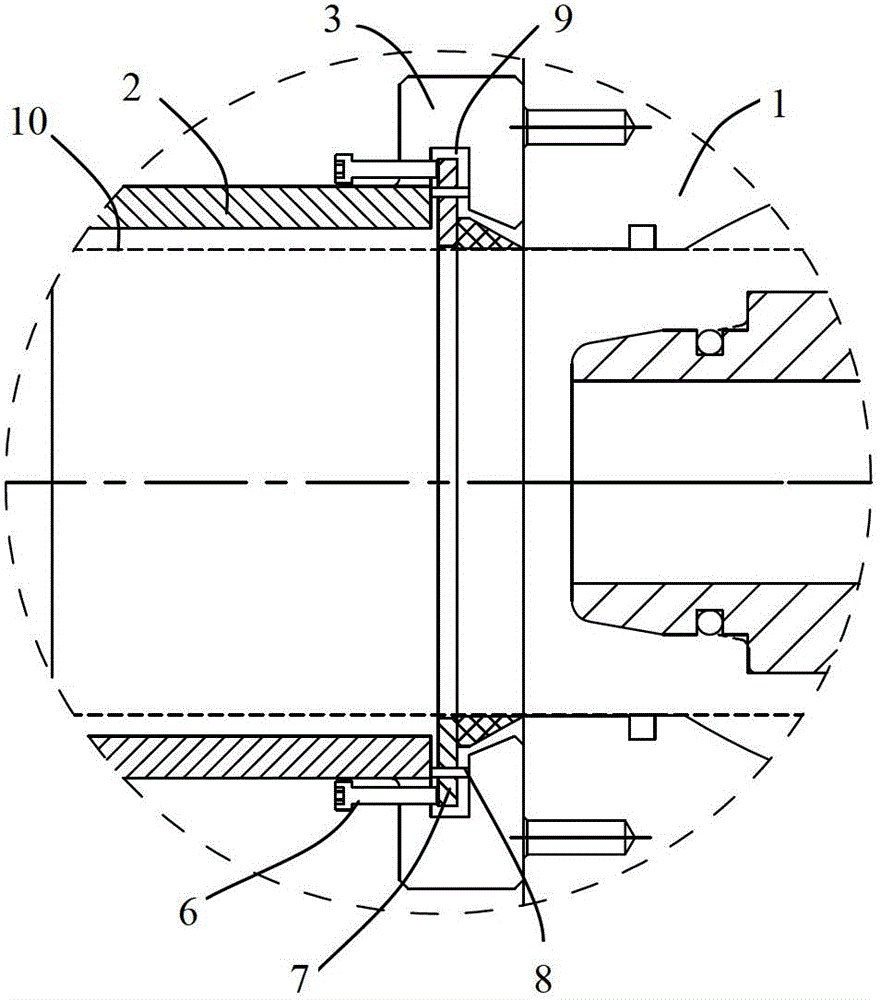

[0012] Such as figure 1 As shown, the insert positioning structure in the mold of the present invention includes a sleeve 2 and a block 3, the block 3 is annular, the sleeve 2 is fixedly connected to the block 3, and the block 3 is connected to the mold The body 1 is fixedly connected. The sleeve 2 is provided with at least one positioning groove (not shown in the figure) along the circumferential direction of the sleeve, and the first polytetrafluoroethylene protective sleeve 4 is installed in the positioning groove, as shown in the figure, the A positioning groove is arranged inside the casing 2, and a first polytetrafluoroethylene protective sleeve 4 is correspondingly arranged in the positioning groove. A second polytetrafluoroethylene protective sheath 5 is arranged inside the block 3 .

[0013] As a preferred solution, in the present invention, the inner surface of the block 3 is provided with a groove 9 along the circumferential direction of the block, and the groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com