A kind of method that liquid phase oxidation method prepares 2-bromofluorenone

A liquid-phase oxidation method and bromofluorenone technology, applied in the field of fine chemicals, can solve the problems of high product cost and low yield, and achieve the effects of reducing production efficiency, less solvent consumption, and reducing recovery losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

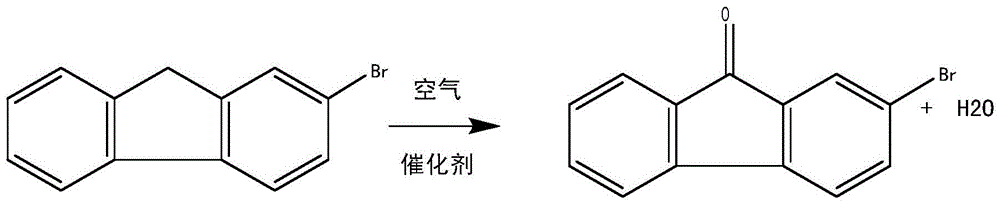

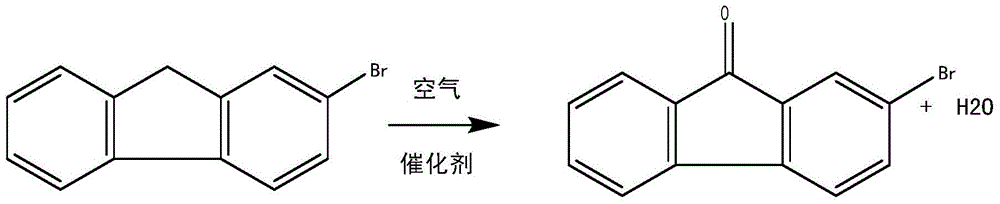

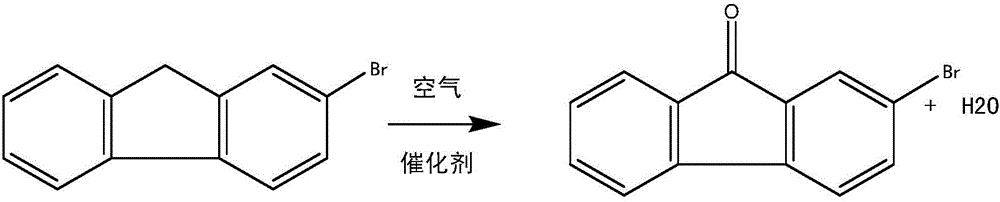

[0015] Example 1: Preparation of 2-bromo-9-fluorenone by oxidation of 2-bromofluorene

[0016] Follow the reaction below,

[0017]

[0018] Operation steps: Add 20 grams of 2-bromofluorene (0.082mol), 80 grams of N,N-dimethylformamide, 1 gram of potassium hydroxide (0.018 mo1), start stirring, react for 2 hours at 35°C, and track through gas chromatography analysis. When the content of raw material fluorene is less than 0.1%, stop ventilating the air and the reaction ends; the reaction solution is filtered after distillation, washed with water, and dried to obtain a purity of 99.5%. % of 2-bromo-9-fluorenone, yield 96%. After the reaction, the used solvent is retained, and the next batch continues to be recycled.

Embodiment 2

[0020] Operation steps: Add 20 grams of 2-bromofluorene (0.082mol), 80 grams of N,N-dimethylformamide (recovered in Experiment 1), and 1 g Potassium hydroxide (0.018mol), start stirring, react at 35°C for 2 hours, track through gas chromatography analysis, when the content of raw material fluorene is less than 0.1%, stop ventilating the air, and the reaction ends; the reaction solution is filtered after distillation, washed with water, and dried. That is, 2-bromo-9-fluorenone with a purity of 99.5% was obtained with a yield of 96%. After the reaction, the used solvent is retained, and the next batch continues to be recycled.

Embodiment 3

[0021] Example 3, Preparation of 2-bromo-9-fluorenone by oxidation of 2-bromofluorene

[0022] Operation steps: Add 20 grams of 2-bromofluorene (0.082mol), 70 grams of N,N-dimethylformamide, 1 gram of sodium hydroxide (0.025 mol), start stirring, and react at room temperature for 3 hours. The reaction solution was filtered after distillation, washed with water, and dried to obtain 2-bromo-9-fluorenone with a purity of 99.4% and a yield of 95.5%.

[0023] Example, Preparation of 2-bromo-9-fluorenone by oxidation of 4,2-bromofluorene

[0024] Operation steps: Add 20 grams of 2-bromofluorene (0.082mol), 90 grams of N,N-dimethylformamide, 1 gram of sodium methylate (0.02mol ), start stirring, and react at 40° C. for 4 hours. The reaction solution was filtered after distillation, washed with water, and dried to obtain 2-bromo-9-fluorenone with a purity of 99.4% and a yield of 95%.

[0025] The physical constants and spectrum data of 2-bromo-9-fluorenone prepared by oxidation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com