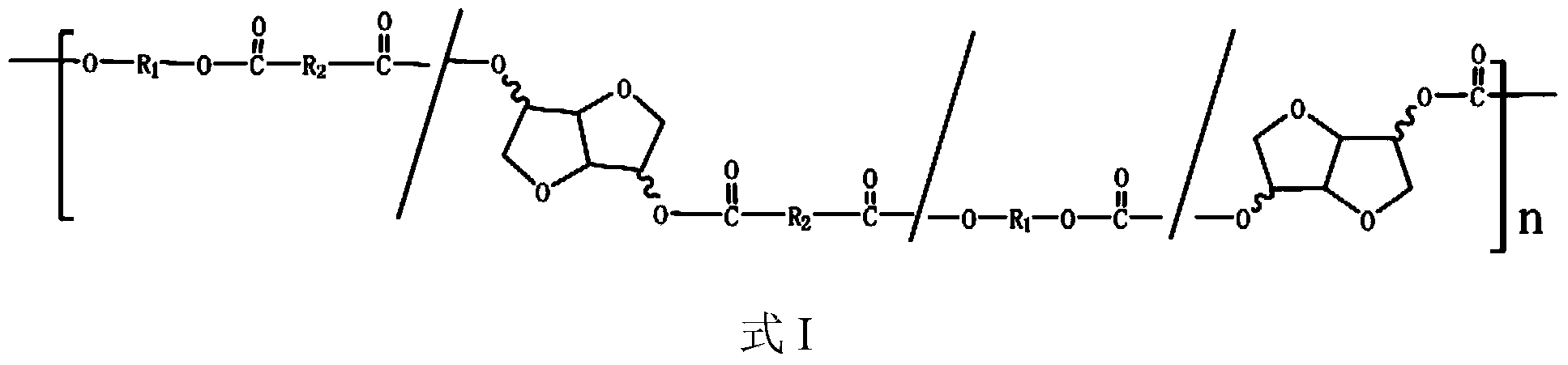

Random copolymer of polycarbonate and aromatic polyester based on 1,4;3,6-diglycidyl hexanehexol and preparation method and application thereof

A technology of random copolymer and aromatic polyester, which is applied to the random copolymer of polycarbonate and aromatic polyester based on 1,4;3,6-dihexylhexyl, its preparation method and application It can solve the problems of high melt viscosity of resin, polycarbonate can not meet industrial use, difficult to mold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

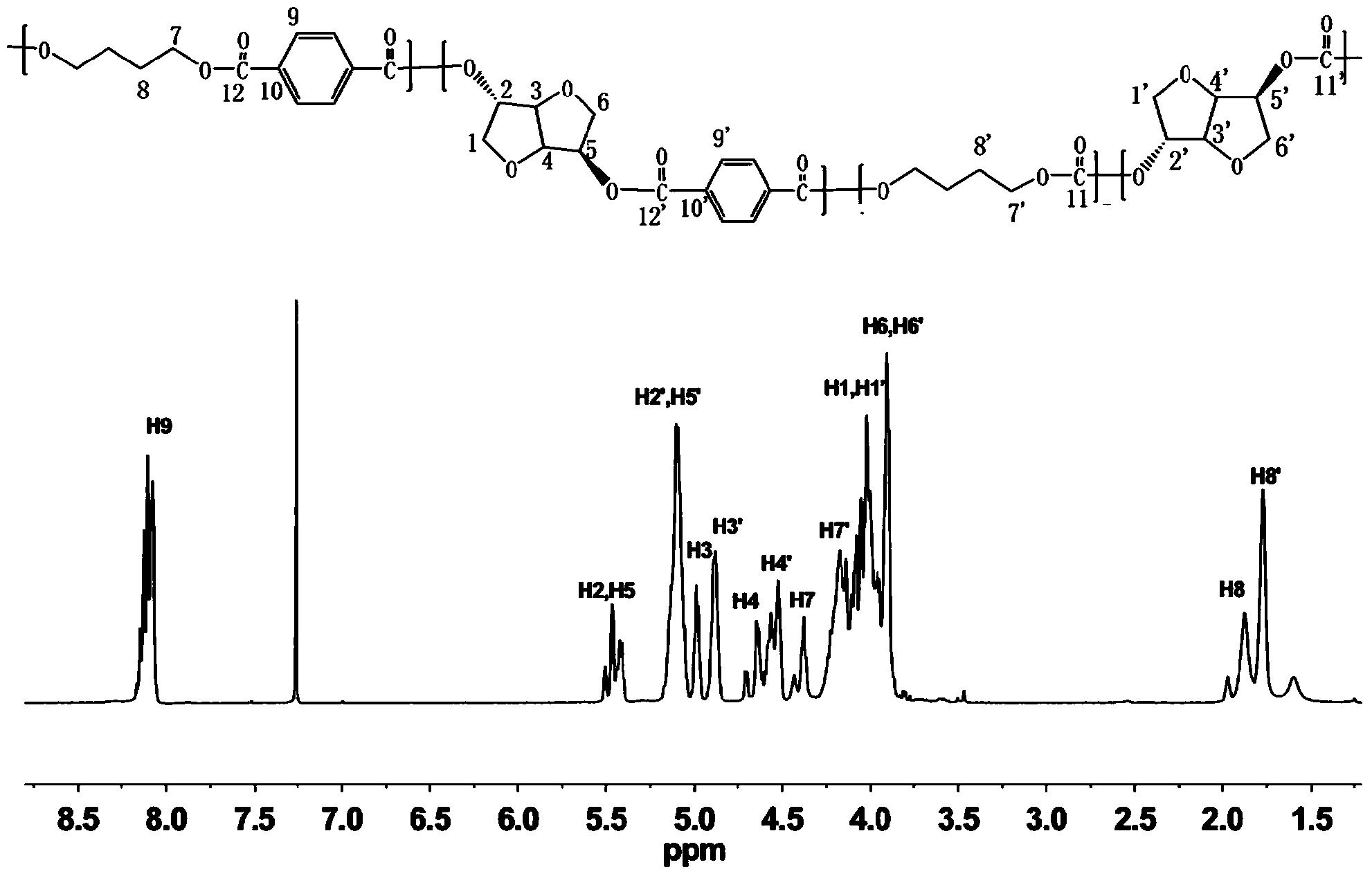

Image

Examples

Embodiment 1

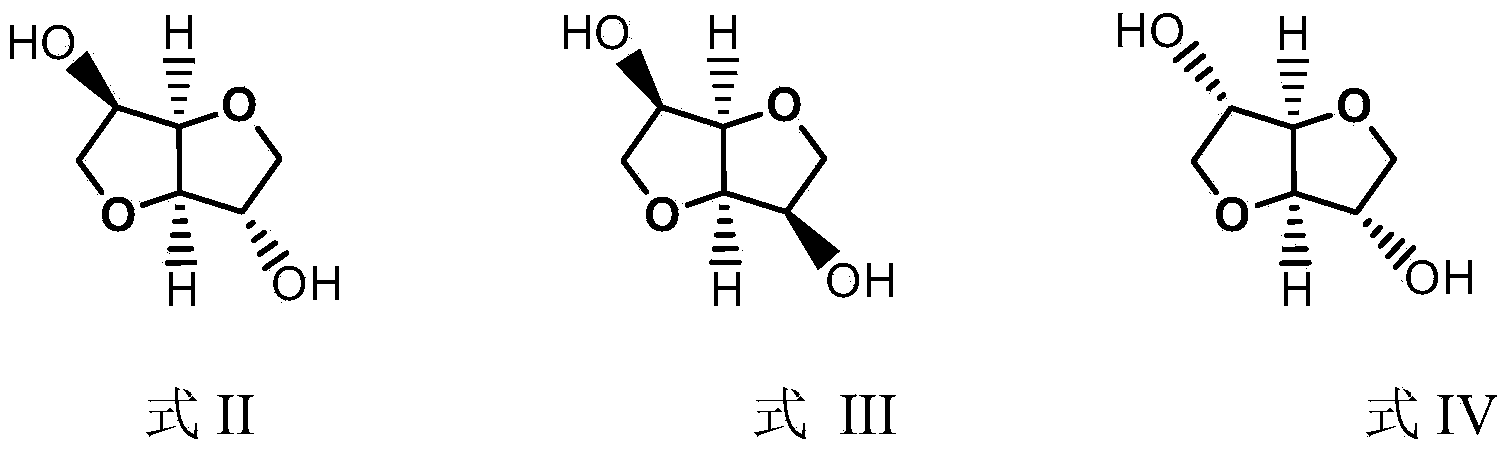

[0058] Embodiment 1. The random copolymer of isosorbide polycarbonate and aromatic polyester is prepared by two pots

[0059] (1) At room temperature, in a 250mL glass flask, add 26.3g (0.18mol) isosorbide, 32.4g (0.36mol) dimethyl carbonate and 0.00026g transesterification catalyst stannous octoate under nitrogen atmosphere, (iso The molar ratio of sorbitol to dimethyl carbonate is 1:2), stirred and reacted at 60°C for 3 hours, then gradually raised the temperature to 220°C, distilled out the by-product methanol produced by the reaction, and stopped the reaction until the reaction was complete. Obtain the prepolymer of isosorbide polycarbonate;

[0060] (2) In a 250mL glass flask, add 3.3g (0.02mol) of terephthalic acid, 3.6g (0.04mol) of 1,4-butanediol and 0.002g of esterification catalyst tetrapropoxytitanium under a nitrogen atmosphere (The molar ratio of terephthalic acid to 1,4-butanediol is 1:2), start stirring at 160°C, gradually raise the temperature to 240°C, and re...

Embodiment 2

[0063] Embodiment 2. The random copolymer of isosorbide polycarbonate and aromatic polyester prepared by two pots

[0064] (1) At room temperature, in a 250mL glass flask, add 28.9g (0.198mol) isosorbide, 89.1g (0.99mol) dimethyl carbonate and 0.02g transesterification catalyst Na 2 CO 3 , (the molar ratio of isosorbide to dimethyl carbonate is 1:5), stirred and reacted at 120°C for 6 hours, then gradually raised the temperature to 220°C, distilled out the by-product methanol produced by the reaction until the reaction was complete, Stop reaction, obtain the prepolymer of isosorbide polycarbonate;

[0065] (2) In a 50mL glass flask, add 0.4g (0.002mol) dimethyl terephthalate, 3.6g (0.04mol) 1,4-butanediol and 0.0001g of zinc acetate (terephthalic acid) under a nitrogen atmosphere The molar ratio of dimethyl diformate to 1,4-butanediol is 1:20), start stirring at 160°C, gradually raise the temperature to 240°C, distill out the by-product methanol produced by the reaction unti...

Embodiment 3

[0067] Embodiment 3. The random copolymer of isoidide polycarbonate and aromatic polyester is prepared by two pots

[0068] (1) At room temperature, in a 250mL glass flask, add 23.4g (0.14mol) isoidide alcohol, 132g (1.12mol) diethyl carbonate and 0.005g transesterification catalyst lithium acetylacetonate (isoaidide) under nitrogen atmosphere The molar ratio of decyl alcohol to diethyl carbonate is 1:8), stirring and reacting at 100°C for 8 hours, gradually raising the temperature to 200°C, distilling out the by-product ethanol produced by the reaction until the reaction is complete, stopping the reaction to obtain Prepolymers of isoidide polycarbonate;

[0069](2) At room temperature, in a 250mL glass flask, add 11.6g (0.06mol) of dimethyl isophthalate, 62.3g (0.30mol) of 1,5-pentanediol and 0.01g of zinc acetate under a nitrogen atmosphere (The molar ratio of dimethyl isophthalate to 1,5-pentanediol is 1:5), start stirring at 150°C, gradually raise the temperature to 230°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap