Straight rib hole lattice brick

A technology of checker bricks and straight ribs, applied in the field of checker bricks, can solve the problems that the change of unit specific surface area cannot be realized, and checker bricks cannot meet the working characteristics of the hot blast stove regenerator at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

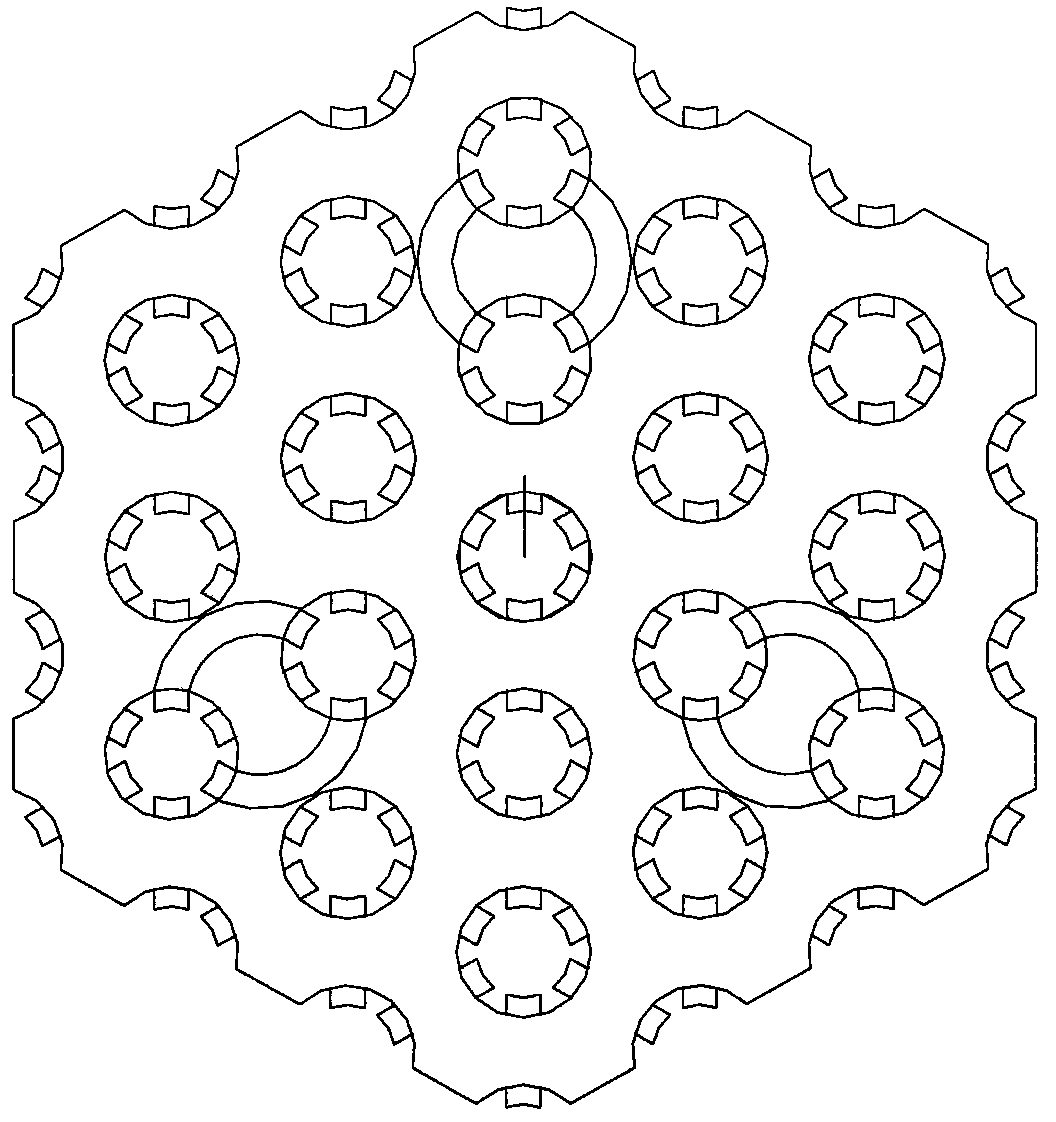

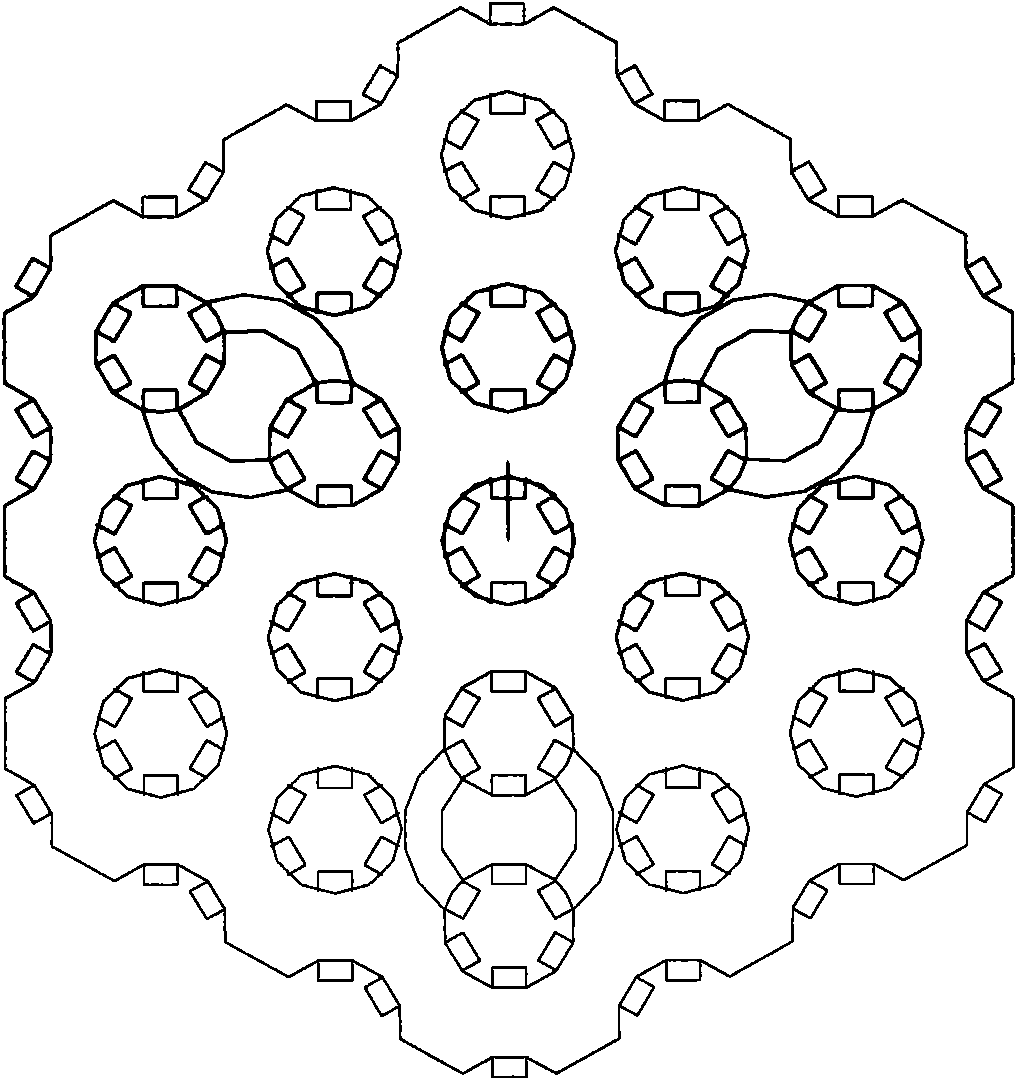

[0022] figure 1 A straight-ribbed cell checker brick (1) according to the invention is shown. A straight-ribbed checker brick (1) has a substantially hexagonal cross-section and has a top surface (2), an opposite bottom surface (3) and six side (9). The straight rib hole checker brick (1) has a plurality of circular passages (4) extending from the top surface (2) to the bottom surface (3), so that fluid can flow through the straight rib hole checker brick (1), relatively Partition walls (5) are formed between adjacent channels (4). There are several straight ribs (6) attached to the inner wall of the circular channel (4), and the shape of the straight ribs (6) is a quadrilateral, which is composed of two concentric arcs and two straight lines parallel to the center of the circle, one of which is a circle The arc coincides with the circle of the circular channel (4), the vertical distance between the end surface (7) and the top surface (2) of the straight rib (6), the end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com