Real-time rubber waterstop monitoring method for immersed tunnel and rubber waterstop

A rubber waterstop, real-time monitoring technology, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve the problem of floating, unable to quantitatively monitor the compression of the GINA rubber waterstop, and the failure of the waterstop function, etc. problems, to achieve the effect of increasing the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

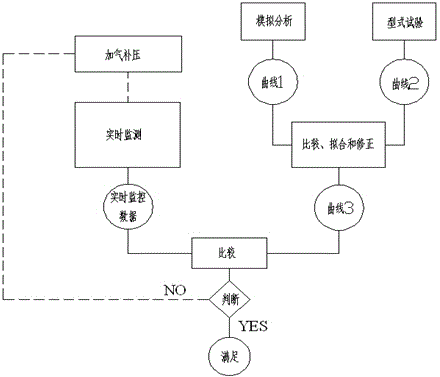

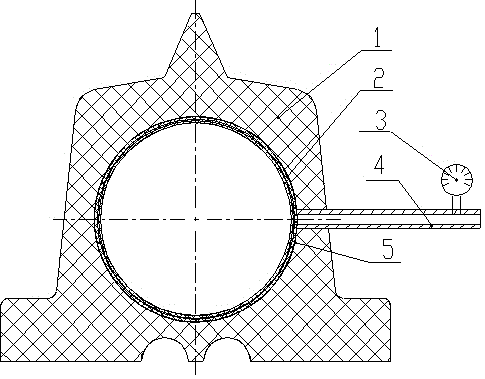

[0034] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the description of the embodiments. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention. For Those of ordinary skill in the art can also obtain other drawings based on these drawings without making creative efforts.

[0035] In the immersed tunnel, the water-stop characteristics of the rubber waterstop determine the normal operation of the immersed tunnel. As the main waterproof device of the immersed tunnel, the rubber waterstop directly determines the operation of the tunnel; For the "ten tunnels and nine leaks" in the industry, the main reason is that the immersed tube tunnel is constructed and operated underwater, and the installation and detection of rubber waterstops are very difficult. In the immersed tube tunn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com