Oil well measurement tool

A measurement tool and oil well technology, applied in the direction of measurement, wellbore/well components, earthwork drilling and production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

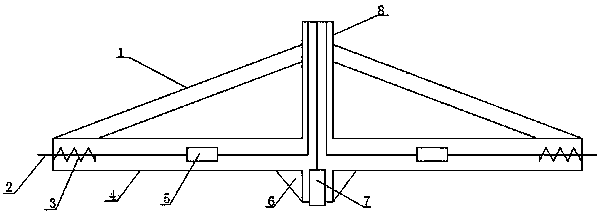

[0016] Such as figure 1 The shown oil well measurement tool includes horizontal hollow tubes 4 and vertical hollow tubes 8 that are vertically connected to each other. The internal cavities of the horizontal hollow tubes 4 and the vertical hollow tubes 8 communicate with each other, and the ends of the horizontal hollow tubes 4 are sealed , the two ends of the inner cavity of the horizontal hollow tube 4 are provided with a displacement sensor 5, one end of the displacement sensor 5 is a displacement measuring end, the displacement measuring end is connected to the horizontal measuring rod 2, and one end of the horizontal measuring rod 2 extends out of the horizontal hollow tube 4 , and the horizontal measuring rod 2 can move axially in the horizontal hollow tube 4, the horizontal measuring rod 2 is also connected to the fixed spring 3 fixedly connected with the horizontal hollow tube 4 in the axial direction, and the lower end of the vertical hollow tube 8 is set There is a ...

Embodiment 2

[0020] This embodiment adds the following structure on the basis of Embodiment 1: the lower end of the vertical hollow tube 8 is also provided with a weighted plate 6, the number of the weighted plate 6 is an even number greater than or equal to 2, and the weighted plate 6 is arranged along the vertical 8 circumferences of straight hollow pipes are evenly distributed.

[0021] In this embodiment, in order to ensure accurate measurement and prevent tool shaking from affecting the measurement, therefore, in order to reduce the shaking of the tool during lowering, a weighted plate 6 is specially provided at the lower end of the vertical hollow tube 8, through which the weighted plate 6 increases the size of the tool. The weight in the middle enables the tool to better maintain inertia, maintain a vertical and steady decline, and improve measurement accuracy. In order to maintain balance, the number of weight plates 6 should be an even number greater than or equal to 2, and the wei...

Embodiment 3

[0023] The present embodiment adds a balance bar on the basis of embodiment 1 or embodiment 2, specifically: it also includes a balance bar 1 arranged at both ends of the horizontal hollow tube 4, the balance bar 1 is inclined, and the upper end of the balance bar 1 is connected to the Vertical hollow pipe 8 is connected.

[0024] In this embodiment, the balance bar 1 and the two ends of the horizontal hollow tube 4 respectively form a triangular structure, which can not only increase the strength of the horizontal hollow tube 4, so that it can be used for a long time without deformation, but also the balance bar 1 can maintain the horizontal hollow tube. The two ends of 4 are balanced so that no upward and downward inclinations can occur, and the level of the horizontal hollow tube 4 is excellently guaranteed, and the practicability is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com