A fiber Bragg grating sensor paste method

A grating sensor, fiber optic Bragg technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of sensor damage, insufficient strain transmission, poor repeatability, etc., to achieve stable strain sensitivity coefficient, ensure effectiveness and reliability , the effect of high strain transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

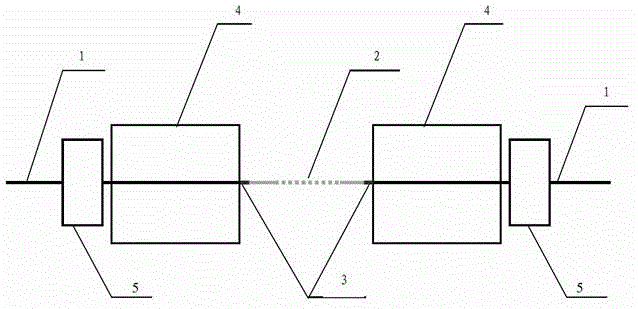

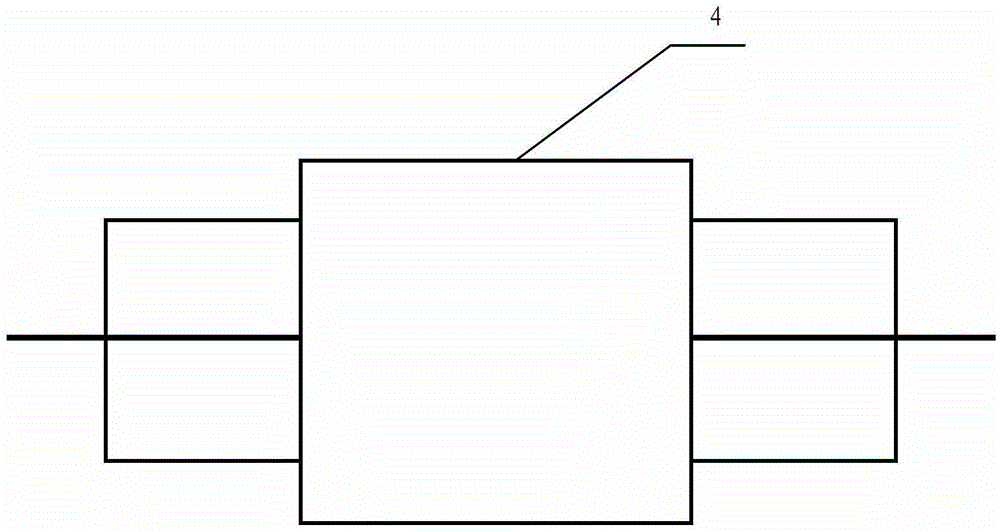

[0023] The study found that the average strain transfer rate of the sensor decreases with the increase of the thickness of the adhesive layer, and increases with the increase of the bonding length, and the greater the elastic modulus of the adhesive layer, the greater the average strain transfer rate. Therefore, it is necessary to comprehensively consider various factors affecting the strain transfer, not only to ensure a high strain transfer rate, but also to ensure the consistency and stability of the strain sensitivity coefficient, and to make the sticking length as small as possible.

[0024] To ensure a high strain transfer rate, it is necessary to reduce the paste thickness and increase the paste length, but the paste length should not be too long. After analysis and test verification, the strain transfer rate is higher when the paste length is 20-25 mm. To ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com