FBG (Fiber Bragg Grating) high-strain-transmissibility rapid pasting and laying method for wind power blade under high humidity

A wind power blade, high humidity technology, applied in wind power generation, mechanical equipment, wind turbines, etc., can solve the problems of long blade production cost, strain monitoring effect, fiber breakage and sticking off, etc., to reduce the use cost, guarantee Strain monitoring stability, the effect of ensuring paste stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

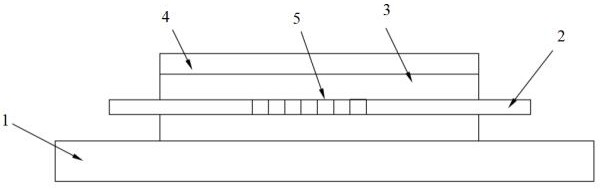

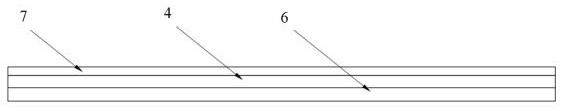

[0059] Such as figure 1 Shown is a layout method of a surface-mounted FBG strain sensor with high humidity resistance and fracture resistance applied to wind power blades, including surface-mounted FBG sensors, wind power blades, demodulators, optical fiber sensor connectors, 0.27mm thick glass fiber prefabricated Dipping material, Loctite fast two-component epoxy glue.

[0060] Such as figure 1 , image 3 , Figure 4 Shown is a method for pasting a surface-mounted FBG strain sensor that is resistant to high humidity and breakage for wind power blades.

[0061] Step 1: Conduct tensile and shear experiments according to Figure 9 When the environment is determined to be 80% RH, the colloid model is Loctite fast two-component epoxy resin glue

[0062] Step 2: Carry out finite element simulation on pasted parameters according to Figure 7 , Figure 8 Take three effective figures for the strain transfer rate to get the pasting parameters: the pasting width is 11mm, and the ...

Embodiment 2

[0069] Such as figure 1 , Figure 5 , Image 6 A layout method of high strain transfer rate of wind turbine blades based on FBG fiber Bragg grating sensor is shown, including the following steps:

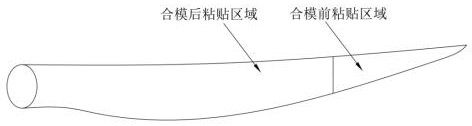

[0070] Step 1: Determine the size of the blade, and select the laying distance of the blade tip before mold closing according to the deepest distance that the laying personnel can enter into the complete blade.

[0071] Step 2: Before closing the mold, use a high-efficiency fusion splicer to connect two adjacent FBG sensors that need to be connected in series at the tip curvature of the determined distance

[0072] Step 3: Paste the white paper on the side of the prepreg white paper to the W-shaped mold with double-sided tape and tear off the plastic film, press and paste the connecting wires of the two FBG sensors on the prepreg, and evenly coat the prepreg Thai fast two-component epoxy resin adhesive.

[0073] Step 4: Use a W-shaped mold to press the adhesive-coated prepreg on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com