Vibration absorber dust-proof cover

A technology of dust cover and shock absorber, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of shock absorber pollution, functional failure, damage, etc. Breakage, increased product life, high radial deformation and effects of breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

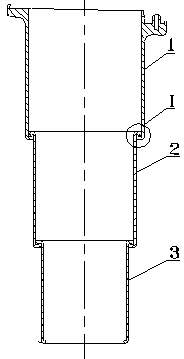

[0022] The structure and working method of the present invention are further described in detail below in conjunction with specific drawings:

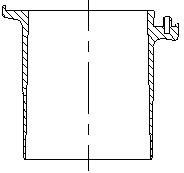

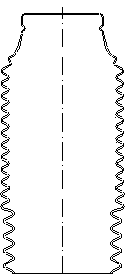

[0023] see image 3 , the shock absorber dust cover proposed by the present invention is composed of the following three parts: the upper sleeve 1, the connecting sleeve 2, and the lower sleeve 3. The inner diameters of the three parts are successively reduced. The sleeve 3 is inserted into the connecting section sleeve 2, and then the combination of the connecting section sleeve 2 and the lower section sleeve 3 is inserted into the upper section sleeve 1, and the ends of the three section sleeves are provided with inward or outward Hook, such as the upper hook structure a or the lower hook structure b, the upper hook structure and the lower hook structure are interlocked to form the cooperation of the hook structure, see Figure 4 , under the action of the hook structure of the three parts, the three sections can be connected reliabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com