Vibration Elimination Equipment for Steam Condensate Pipeline

A steam condensation and vibration elimination technology, applied in the direction of mechanical equipment, pipe components, pipes/pipe joints/fittings, etc., can solve problems such as hidden dangers of pipeline safety operation, achieve good mixing effect, reduce the effect of velocity gradient and quality gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

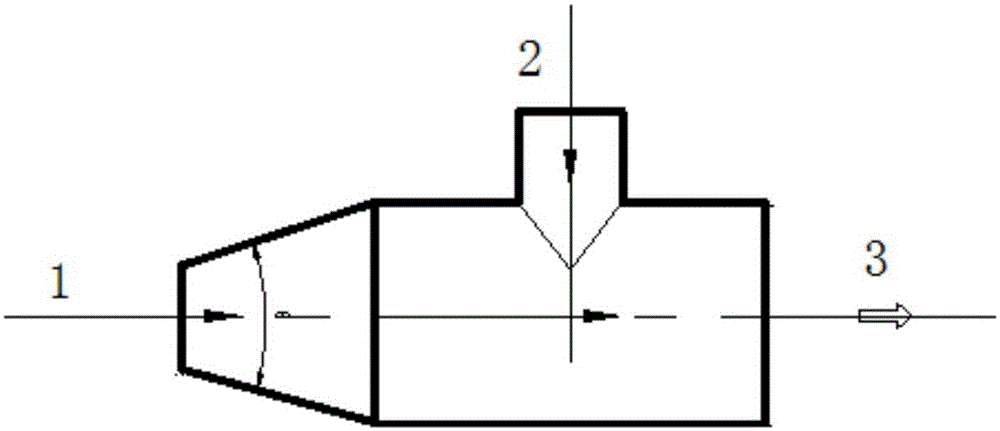

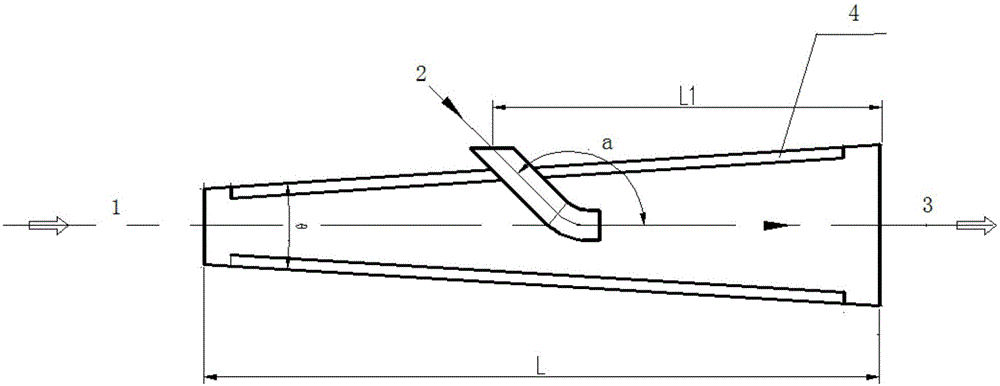

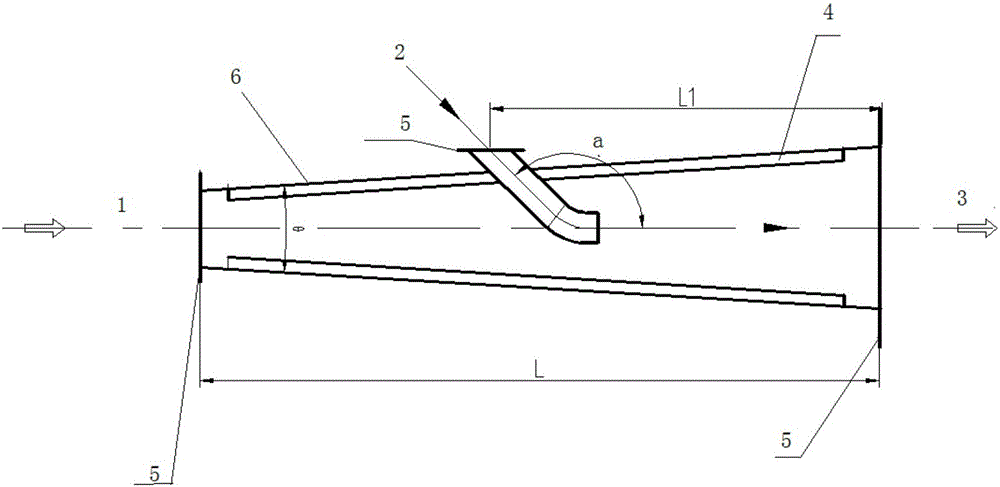

[0017] The present invention is described in detail below in conjunction with accompanying drawing:

[0018] A steam condensate pipe vibration elimination device, including a tapered pipe 6, the inner surface of the tapered pipe 6 is evenly provided with N pieces of guide plates 4 radially symmetrically distributed along the pipe circumference; and the small diameter of the tapered pipe The end is connected to the condensate I1, and an elbow for connecting the condensate II is inserted obliquely on the conical pipe. The output end of the elbow is the same as the medium flow direction of the condensate I1 and condensate II in the conical pipe; the conical The large-diameter end of the pipeline is the medium outlet 3 where the condensate I1 and the condensate II2 are collected. The elimination equipment is used to install at the confluence pipeline of steam condensate at different pressures and temperatures, so that different fluids can be fully mixed in the same flow state to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com