Preparation method of bamboo winding composite vertical storage tank

A technology for vertical storage tanks and storage tanks, which is applied in the direction of fixed-capacity gas storage tanks, mechanical equipment, sustainable manufacturing/processing, etc., to achieve the effects of reducing costs, increasing comprehensive utilization, and saving oil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

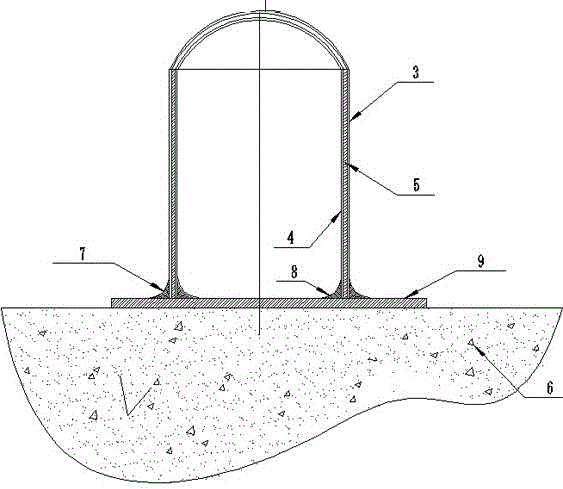

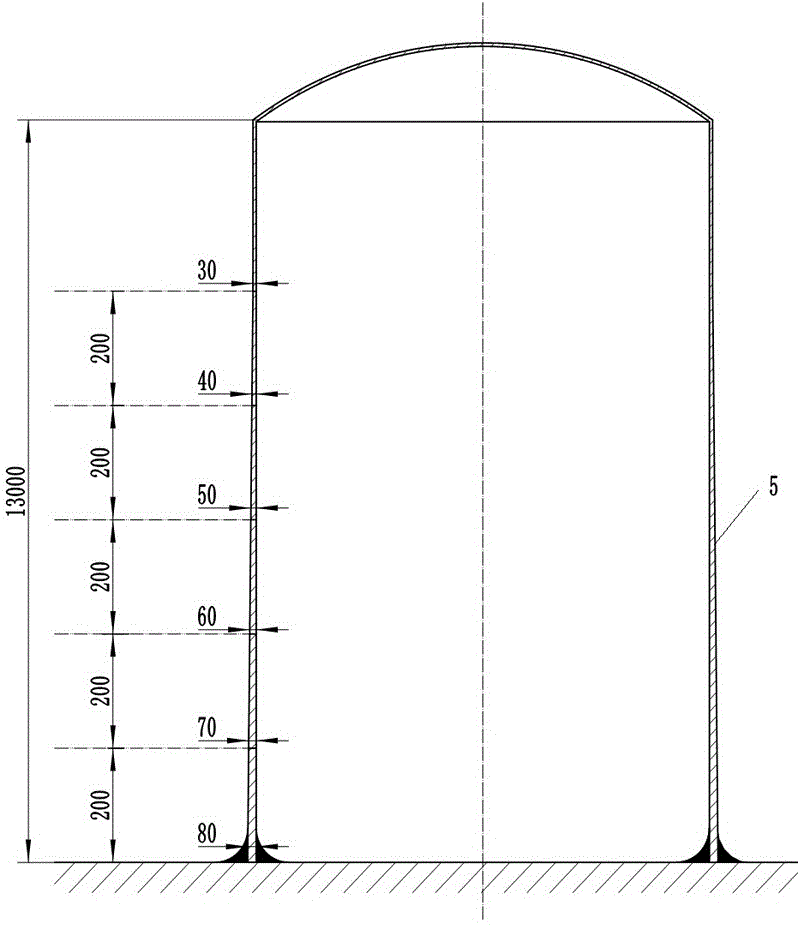

[0024] This embodiment takes a vertical storage tank with a capacity of 1000m3 as an example, its diameter is 10000mm; its height is 13000mm.

[0025] The bamboo fiber felt that adopts in the present embodiment is a kind of bamboo fiber non-woven fabric, is prior art.

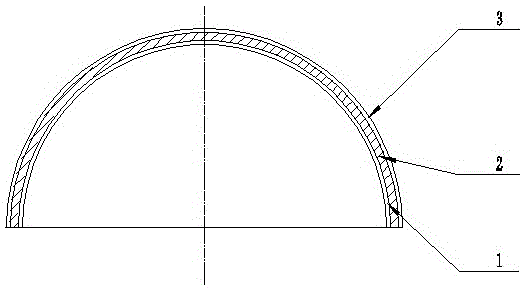

[0026] 1. The preparation method of the top head.

[0027] 1. Make the inner lining of the head.

[0028] The above-mentioned bamboo fiber felt is adhered on the top head mold through resin, and the resin preferably adopts a resin with good anti-corrosion performance to form an anti-seepage, anti-corrosion and smooth inner wall lining layer of the top head of the storage tank.

[0029] 2. Make bamboo strip rolls.

[0030] Moso bamboo is opened into bamboo strips, length 2000mm, width 5mm and thickness 0.8mm. Then dry to a moisture content of 5%-8%, and finally the bamboo strips are connected into a continuous strip of bamboo strips by means of mesh cloth bonding, and rolled into rolls.

[0031] 3. Make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com