Method for detecting and analyzing printing quality of decorative paper

A printing quality and analysis method technology, applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of material waste, low production efficiency, unstable color reproduction quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

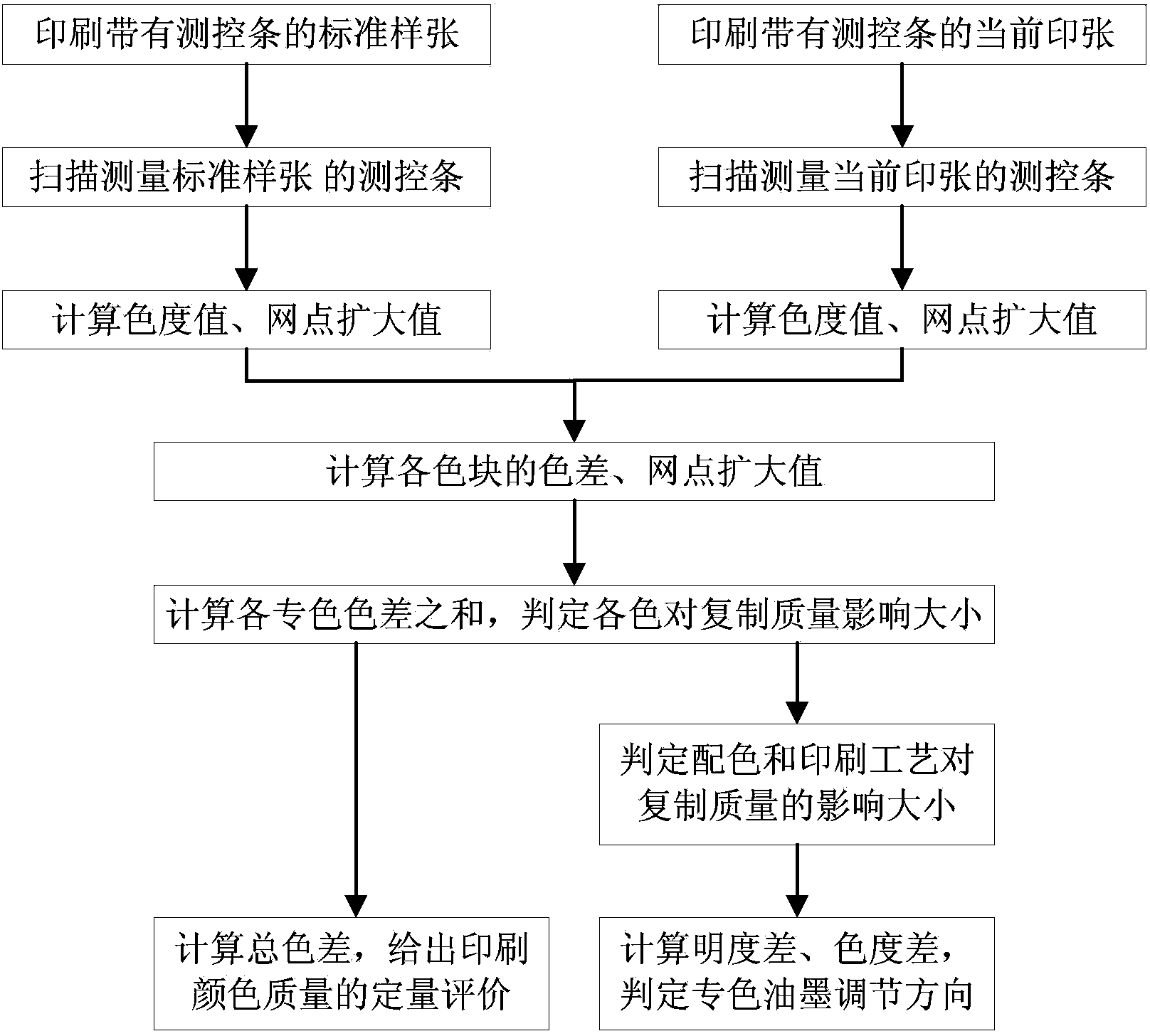

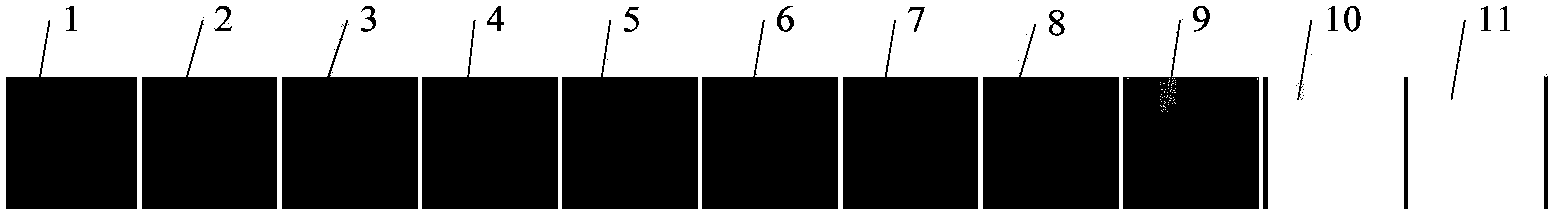

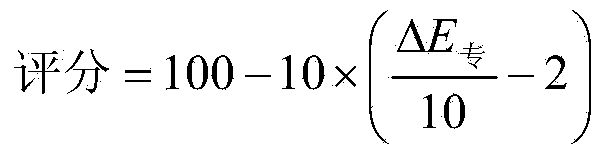

[0020] Decorative paper generally uses gravure and water-based inks to reproduce patterns such as colored wood grains in the form of multiple spot color screening and overprinting. During the printing process, printing workers take sample sheets, mainly relying on visual experience to evaluate the difference between the pattern color of the current printed sheet and the pattern color on the standard sample sheet, estimate the cause of the difference based on experience, and then take corresponding adjustment measures. Since the color pattern is overprinted by multiple spot colors, relying on human experience, it is difficult to judge which color difference of the printed product is caused by improper reproduction of one or several spot colors; even if it is determined that a certain spot color is improperly reproduced , It is also difficult to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com